Seed Hawk TOOLBAR 2011 User Manual

Page 55

Seed Hawk Manual

Tool Bar

Page 50

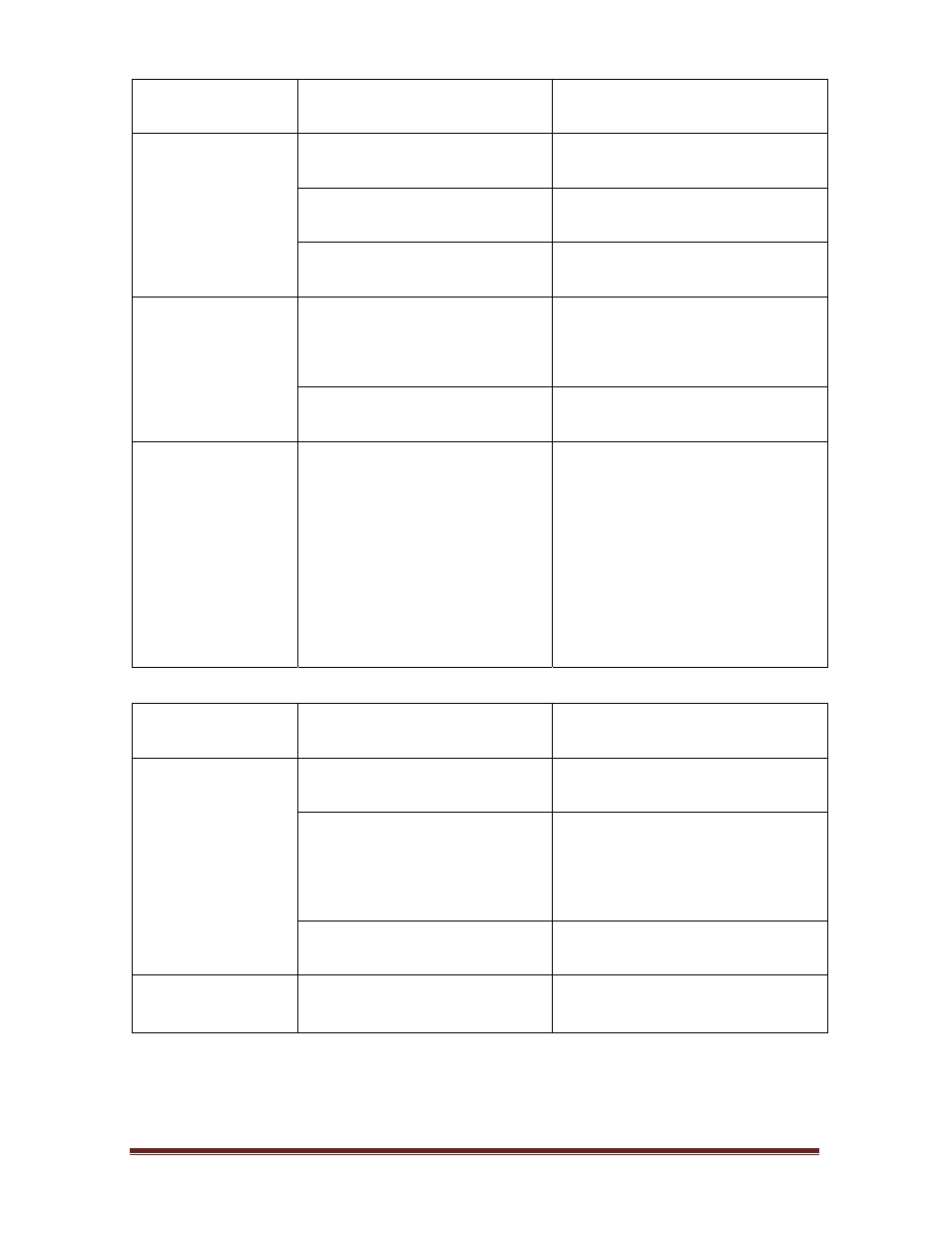

SYMPTOM

POSSIBLE CAUSE

SOLUTION

Wing hydraulic

system does not

maintain pressure.

The “IN” pressure gauge

indicates less than 1200 lb

f

/in

2

(8

275 kPa).

Inspect quick couplers to ensure

complete engagement.

Check 7plex wing down value.

(only on 7plex machines. 72 feet

and up)

Remove, inspect o-rings, clean and

replace cartridge if necessary.

Wing lift cylinder piston leaking.

Remove hose from rod end of

cylinder. If oil discharges, seal is

leaking. Remove and replace seal.

Wings do not raise.

The “IN” pressure gauge

indicates less than 1200 lb

f

/in

2

(8

275 kPa) for smaller implements

and less than 2100 lb

f

/in

2

(14.50

kPa) for larger implements.

Inspect quick couplers to ensure

complete engagement. Check to see

that the circuit is putting out enough

pressure.

Wing cylinder piston seal leaking.

Remove hose from rod end of

cylinder. If oil discharges, seal is

leaking. Remove and replace seal.

Cannot maintain

packing pressure or

shanks will not stay

up in transport.

Seal damaged in shank cylinder.

Check o-rings on meter engage

valve also make sure meter

engage switch is shut off.

Pressure shanks up and keep locked

on. Undo main bridle hoses on the

rod end of cylinder on both ports. If

oil is flowing out of a hose, then it is

that rank on that wing that has a seal

leak. Move down that rank, undoing

the hoses on the rod end of each

cylinder. When the oil quits flowing, it

is the previous cylinder with the

faulty seal. Replace cylinder seal(s)

and repeat process in case of more

than one faulty seal.

SYMPTOM

POSSIBLE CAUSE

SOLUTION

Shanks do not

maintain trip/packing

pressure in hilly

terrain.

The “IN” pressure gauge

indicates less than 1200 lb

f

/in

2

(8

275 kPa).

Inspect quick couplers to ensure

complete engagement.

Excessive field operating speed.

Reduce field operating speed.

Note: Trip/packing pressure may be

momentarily increased by activating

hydraulic Circuit #1 while passing

through a shallow dip in the terrain.

Intermittent electrical power

supply to shank solenoid coil.

Ensure all electrical connections are

fully engaged and no open electrical

circuits to coil.

Shanks will not go

down under pressure

Pivot points are too tight or

seized.

Loosen up pivot points about 1/8 of a

turn. Don’t over loosen them.