Exhaust safety when pumping hazardous liquids, High temperature instructions – SANDPIPER X50 Full Flow User Manual

Page 9

b50ffaa_x50ffaa_manual-rev0911

HG-CF-1087 rev.G 09.01.2011

HG -CF -1087 Rev. E – 15.02.10

PAGE 9

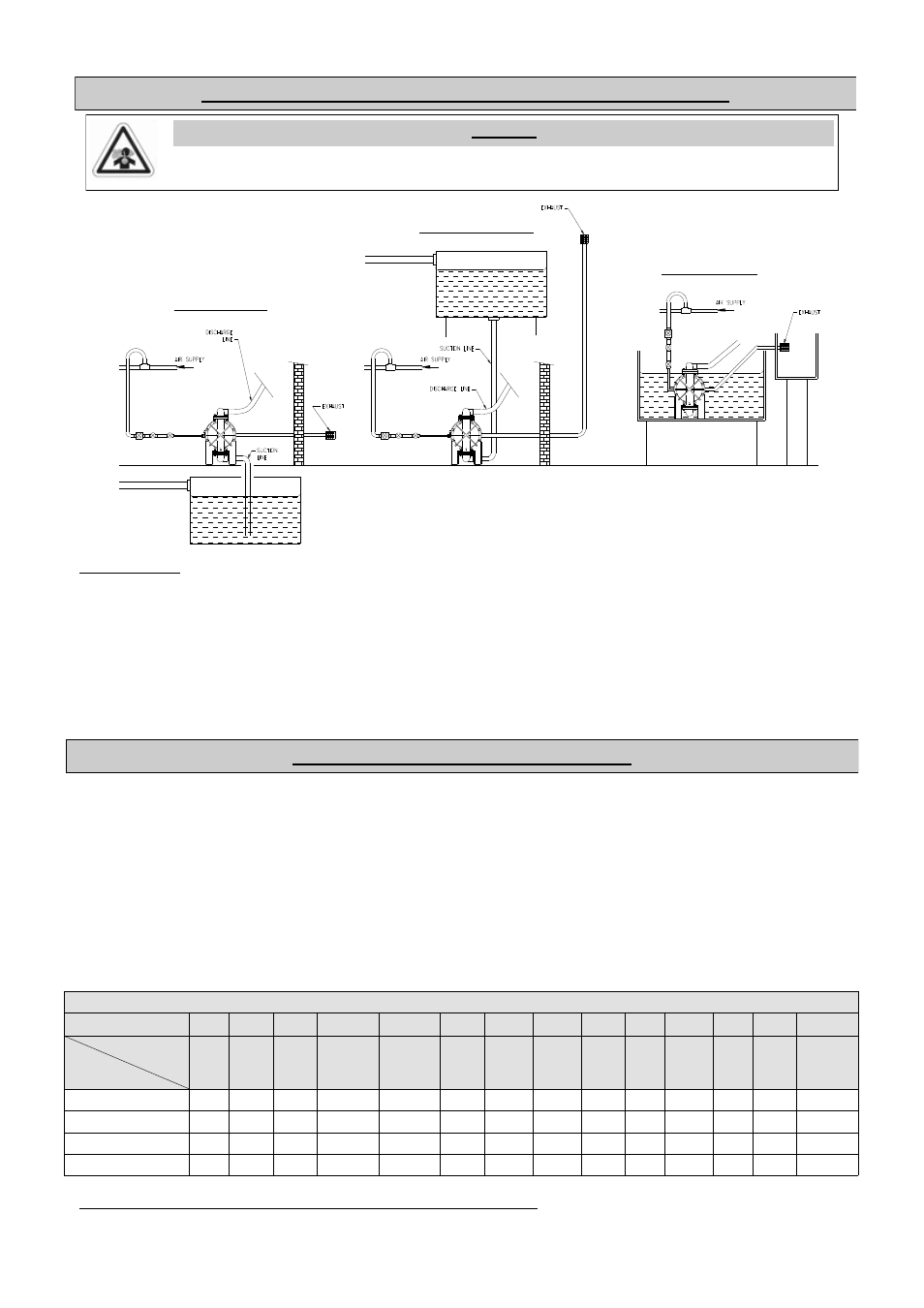

EXHAUST SAFETY WHEN PUMPING HAZARDOUS LIQUIDS

Suction Lift Installation

Flooded Suction Installation

Submerged Installation

Exhaust Safety :

-

When a diaphragm fails during operation, pumped liquid can enter and contaminate the air side of the pump. If diaphragm failu

re is not

severe, i.e. a small split or hole, then the pump can continue to run, with air being forced into the product being pumped. I

f however the

failure is more serious, then the pump may stop, with fluid or fumes being expelled through the exhaust. Under these conditio

ns it is

recommended that the exhaust is piped away to a safe area. In standard suction lift conditions this can simply be done by pip

ing from the

exhaust connection to a safe area. Multiple installations can be piped to a common connection, then to a safe area. In floode

d s uction

conditions the exhaust must be taken to a point higher than the fluid level to prevent any siphoning away. In submerged condi

tions ensure

exhaust is piped away above fluid level.

In all conditions ensure exhaust outlet is not expelling across a non

-conductive surface. The exhaust must not be placed less th

an 100mm

from any non -conductive surface, as this may generate a propagating brush discharge resulting in a possible ignition source.

In the event of diaphragm rupture, pumped material may enter the air end of the pump, and be discharged into the atmosphere.

If pumping

a product which is hazardous or toxic, the air exhaust must be piped to an appropriate area for safe disposition.

WARNING!

HIGH TEMPERATURE SPECIFICATION

REF. NO

7

13

35

37

38

39

40

41

43

44

45

46

51

28

MATERIAL

DESCRIPTION

BUMP

STOP

O-RING

O-RING

DIAPHRAGM

SHAFT

BUSH

LIP SEAL

(DIA.

SHAFT)

O-RING

LIP SEAL

SPACER

BUSH

SPACER

BUSH

O-RING

BUMP

STOP

VALVE

BLOCK

SEAL

PLATE

SEAL

O-RING

SUPPORT

DIAPHRAGM

VITON

-

-

-

-

-

-

-

-

1B177

50-282

1B176

G329

1B003

PHOSPHOR BRONZE

-

-

-

-

-

-

-

-

NOTE! For part numbers not shown please refer to manufacturer for spec.

In situations where the temperature of the fluid to be pumped is likely to exceed 100°C, a high temperature pump

code must be specified. This is signified using an ‘X’ in the last part of the pump code as shown.

“XTS” in place of “TTS”.

This indicates the following specification amendments :

-

Certain seals and o -rings will be changed from Buna -N to Viton and back -up diaphragms and any bump -stops will

be changed to Viton.

See table below for parts effected : - (refer to main table for quantities / pump)

These items are available in recommended spares kit :

- ASK5005HT

HIGH TEMPERATURE INSTRUCTIONS