5 changing spindle speeds(fig.13) – RIKON Power Tools 70-200EVS User Manual

Page 9

- To adjust tailstock arm in or out, loosen locking arm and turn

handwheel. When the tailstock arm is in a desired position,

tighten locking arm. (See FIG.12)

Handwheel

Tailstock arm

Locking arm

Locking lever

FIG. 12

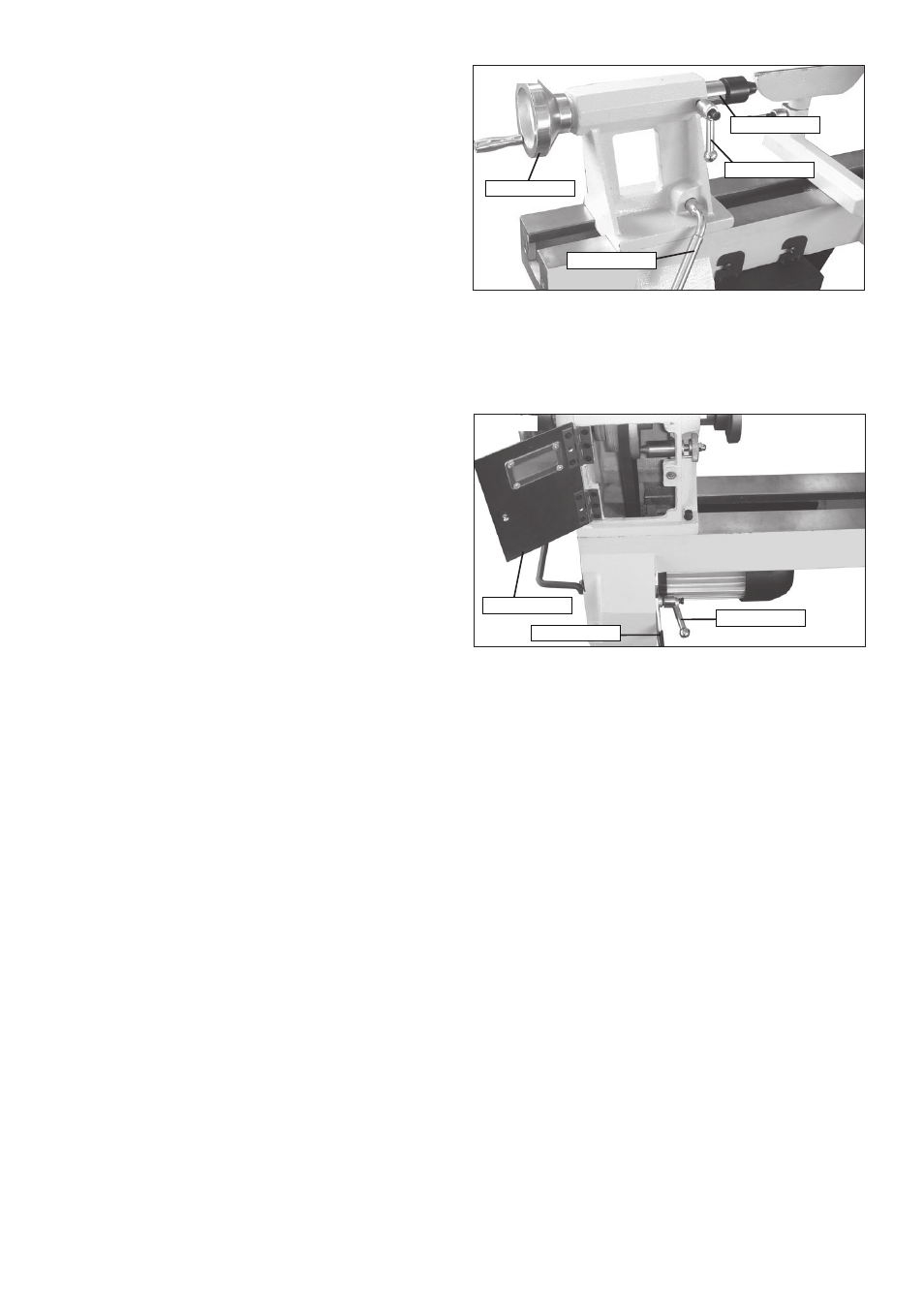

4.5 CHANGING SPINDLE SPEEDS(FIG.13)

- The lathe features three step motor and headstock spindle

pulleys. These three drive ratios are used in conjunction with the

electronic variable speed control to provide maximum power and

speed when required.

- Open both motor pulley and Headstock pulley access doors.

Loosen motor locking arm and raise motor.

Move drive belt to selected drive ratio.

Lower motor for adequate belt tension and tighten locking arm.

(Do not apply excessive load onto the belt prior to locking, as

damage may result.)

-

High ratio range - (small diameter Headstock pulley / large

diameter motor pulley) This ratio is for faster speeds - eg.

Spindle turning and small Faceplate projects.

-

Medium ratio range - (center Headstock / Motor Pulley

diameters) This ratio is suitable for most general woodturning

work such as Spindle and Faceplate projects.

-

Low ratio range - (large diameter Headstock pulley / small

diameter motor pulley) This range will provide maximum lower

speed power ideally suited for larger Bowl turning projects.

- Once the desired ratio has been selected, firstly ensure the

project is fixed to the machine in a strong and safe manner and

fully supported by the Tailstock where possible.

Make sure the speed control knob is set on the slowest "o"

position.

The machine can now be started with the speed control knob

being slowly increased until a suitable and safe cutting speed is

achieved.

NOTE:

For operator safety, always return speed control knob to "O"

position when stopping the machine.

FIG. 13

Access cover

Locking arm

Tension lever

9