Plumbing installation, Initial start up, Pump operation – Davey СxxxA/AB/TB CELSIOR SPA BATH PUMPS User Manual

Page 2: Trouble shooting, Activating air bleed

– 7 –

– 4 –

Plumbing Installation

This product is supplied with barrel unions which accept 40mm PVC pipe.

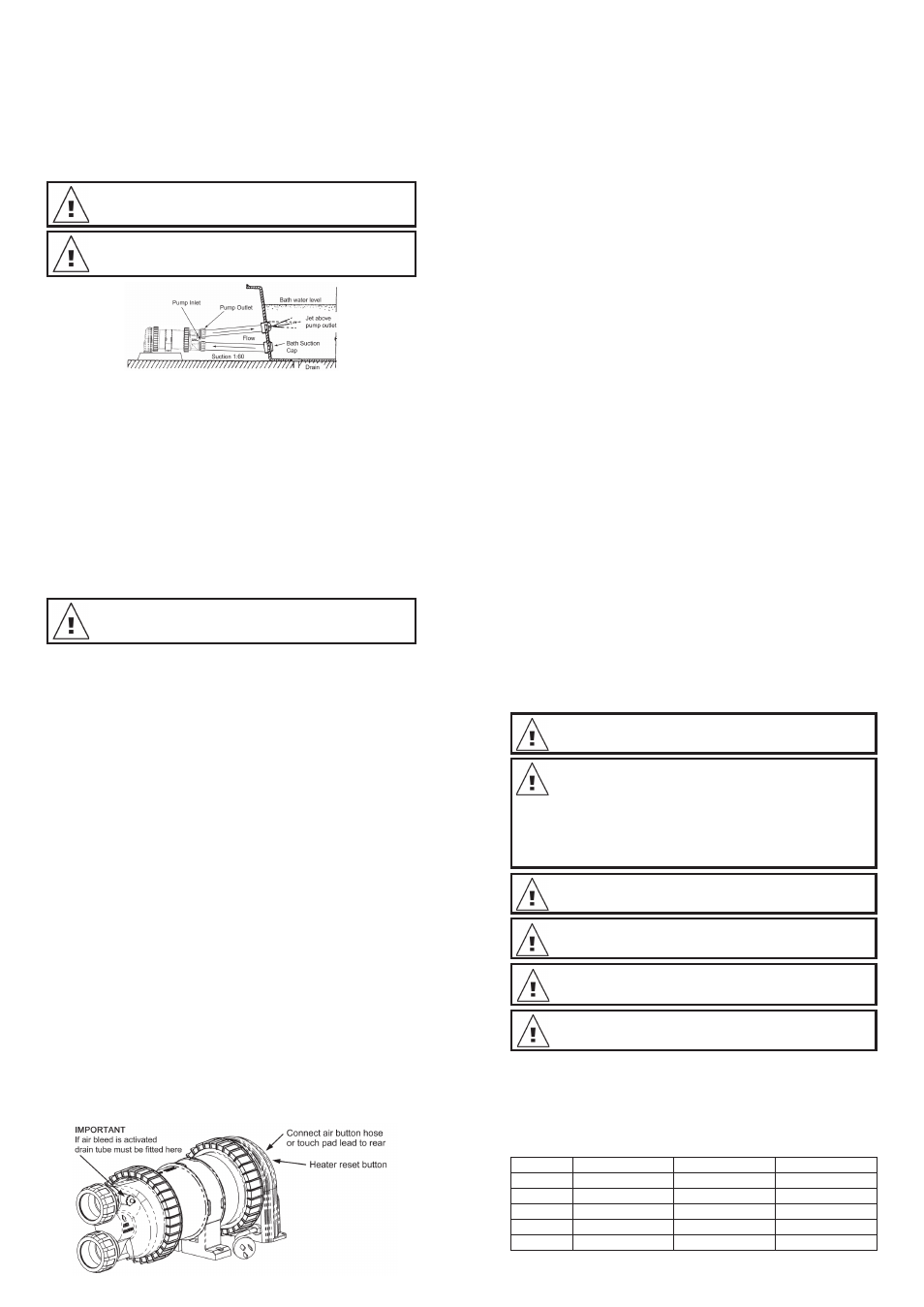

In all cases, the pump must be installed so that the suction line

of the pump slopes from the pump to the bath suction cap with a

recommended minimum gradient of 1:60 or 1 degree. This enables

water to drain out of the pump when it is switched off.

The pump must be installed at a height ensuring the pump discharge

outlet is always below the water level in the bath. This prevents the

pump from getting an air lock (which causes the pump to not fully

prime).

Initial Start Up

Before operating the pump, be sure that no debris or materials are left in

the pipework which may enter the pump and cause an obstruction to flow

or damage to the pump.

1. Check all pipework is properly sealed and firmly fixed (only hand tighten

barrel unions).

2. Fill the bath to the correct level and check pipework for leaks. Activate

the pump, by pushing the air button or touchpad switch. Check for

leaks in the pipe work again.

3. Switch off the pump by pushing the air button or touchpad again.

Pump Operation

Fill the bath to the correct level.

Air Switch Models

Depress the air button to operate the pump. Depress the air button again to

switch off the pump.

– 5 –

Electronic Models

“Spa” button

- turns pump and heater on/off together.

“Boost Heat” button - enables the heater to be turned off/on while pump is

running.

CAUTION

To operate efficiently and prevent pump damage there must be a free flow

of water to and from the pump. Ensure that any valves are appropriately

positioned and there is nothing else preventing the flow of water through

the system.

If the pump stops due to power failure or overheating, turn the pump off

otherwise it will automatically restart when power supply resumes or the

motor cools down.

Avoid filling the bath with very hot water as this may cause “nuisance

tripping” of the element in heated models (refer TROUBLE SHOOTING

section part C). Nuisance tripping can be prevented by partially filling

the bath with cold water and then adding hot water for a comfortable

temperature.

Avoid foreign objects such as tissues or large amounts of hair entering the

bath water as they may be drawn into the pump causing it to jam.

Trouble Shooting

A) If the pump runs, but does not deliver water, the following may be

the cause:

1. The pump is mounted too high relative to the jets in the bath, causing

it

to air lock.

Usually this can be rectified by activating the air bleed (refer to section

ACTIVATING AIR BLEED)

If this fails, the pump will have to be lowered 10 - 15 mm at a time until

it primes (refer to section PLUMBING INSTALLATION).

2. Leak in the suction pipework allowing air to be drawn in.

3. Pipework is blocked.

B) If the motor does not run, the following may be the cause:

1. Power is not connected or a fuse has blown.

2. Overload has been tripped.

The motor is fitted with an automatic re-set overload which is

designed to protect the motor from damage under overload

conditions. Allow the motor to cool and the overload will re-set

automatically to start the pump again. Determine the cause of

overload if possible and rectify. Constant stopping indicates a

problem to be rectified before permanent damage occurs.

– 6 –

3. Air operated switch is in “OFF” condition.

4. The air button on the bath is defective.

5. The electronic touchpad system is defective.

6. The bath water is too hot - add cold water to the bath.

(C) On heated models, if the pump runs but does not maintain water

temperature, the following may be the cause:

Heated pump models feature a back-up protection device which cuts

out the heater and pump if the water temperature exceeds 50°C.

The heater may be cut-out by a thermostat malfunction. However, it is

far more likely to be “nuisance tripped” by filling the bath with very hot

water.

To re-set the heater, press the button on the rear of the pump control

box. If the heater continues to cut-out service attention will be required.

In the event of installation or operation difficulties with your Davey Spa Bath

Pump, contact the supplier from whom the pump was purchased or your

nearest Authorised Davey Pool Equipment Service Centre. For assistance

in locating your nearest dealer contact the Davey Customer Service Centre.

Activating Air Bleed

NOTE:

1. To overcome priming difficulties it may be necessary to activate the

air bleed. To do this, cut end off air bleed valve with a sharp hacksaw.

Connect PVC drain tube to air bleed valve after activation.

2. When air bleed is activated, it is essential that a PVC drain tube

(supplied with pump) is fitted to the barb. Direct tubing up in a loop

above the water level of the bath and then back down again into a

drain or outside of the building, so that any water passing through the

tube will not cause damage.

NOTE: Barrel unions need to be hand tightened only. Do not use tools,

sealants, solvents, lubricants or thread tape. Use of these methods is not

required and may cause damage to the unions or the pump which is not

covered by warranty.

NOTE: Suction and discharge piping, from the pump to the bath, MUST be

installed such that all water drains back to the bath when emptied, and must

be in accordance with local Health Department Regulations (refer to the

following diagram for correct installation).

Never run the pump dry. Running the pump with no water may damage the

mechanical seals, causing leakage and flooding. Dry running damage and

associated damage is not covered under warranty.

Features of this pump are the subject of patent protection in various coun-

tries, as follows :-

PCT/AU01/00490 PCT/AU01/00569 PCT/AU02/00270

Australia 2001254510 2001259939 2002238279

China 01810738.9 01809766.9

*

Europe 01927483.6 01933461.4

*

India -

IN/PCT/2002/01143/DEL

*

USA 10/275,166 10/276,896

*

* national phase entries in progress.

WARNING: Davey Spa Bath Pumps (heated and non heated models)

are capable of pumping water with temperatures up to 50°C. However,

medical authorities recommend that the average temperature of spa water

should not exceed 40°C.

Spa bath pump & pipework hygiene - soap residue and body oil deposits

must be regularly flushed from the spa pipe work to ensure that the spa

does not foster bacteria growth and promote unhygienic conditions.

We recommend that this is preformed at least every month.

1. Fill bath with cold water above jets.

2. Open all jets and air controls.

3. Add a degreaser or sanitiser to the bath water, following

manufacturer’s directions.

4. Run pump for 5 minutes.

5. Stop pump and drain spa. Wipe off any excess deposits on interior of

bath and flush with fresh water.

Commercial or multi-user baths should be flushed between each user.

The appliance is not intended for use by young children or infirm persons

without supervision.

Young children should the supervised to ensure that they do not play with

the appliance.

DANGER - Harzardous suction. Do not block water entry into filtration

system with any part of your body as the pressure can trap hair or body

parts, causing severe injury or death. Do not block suction. Turn off

pump immediately if someone becomes trapped.

Small children using the pool or spa must ALWAYS have close adult

supervision.