Davey Compact Series Underwater Pool Lights User Manual

Page 5

Fibreglass & Above Ground Pool Installations

For Compact Series Underwater Pool Light installations in fibreglass or above ground pool

installations, a light adaptor kit is required as shown below.

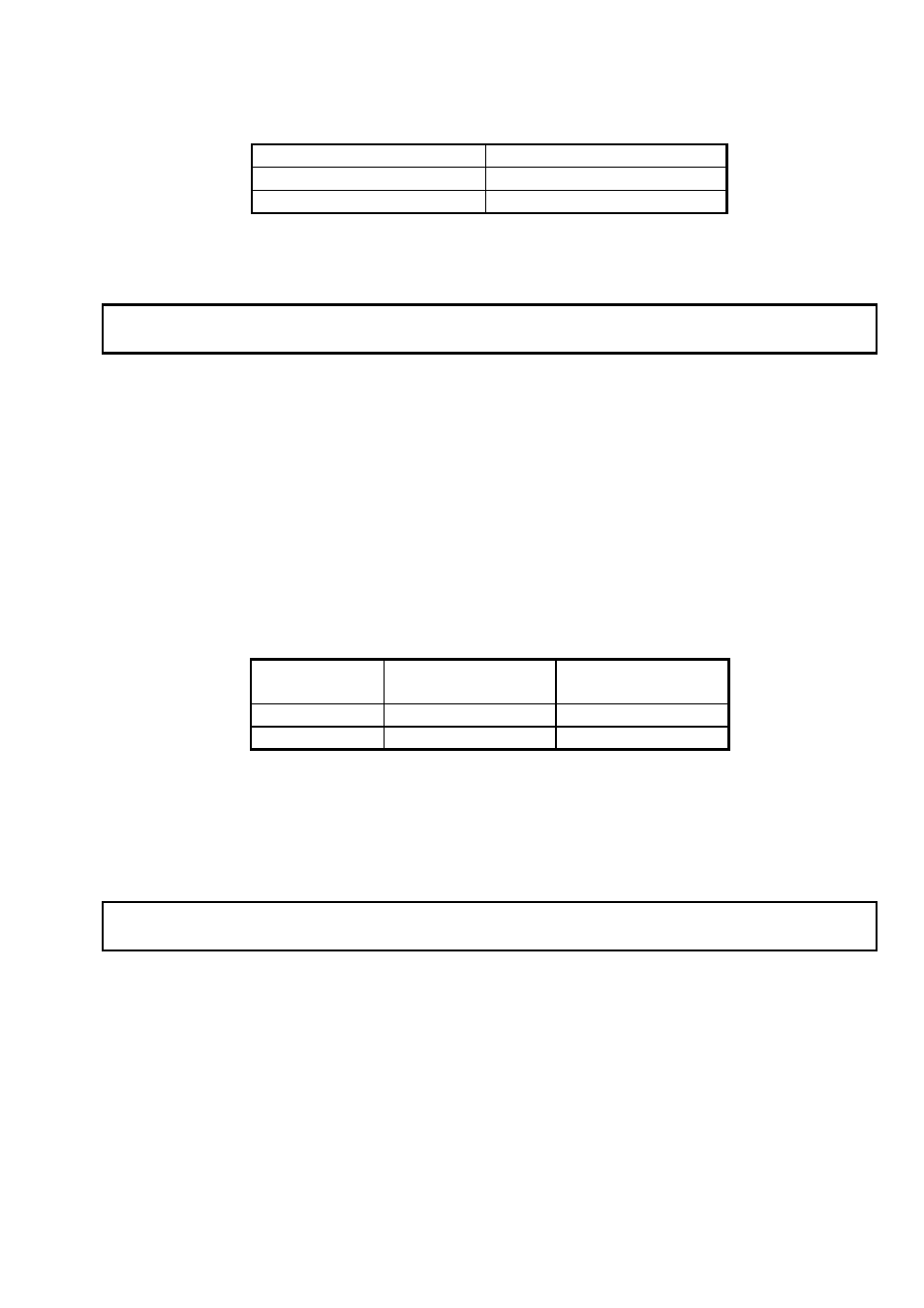

Pool Type

Adaptor Kit Model #

Fibreglass

MS7061100

Above Ground Vinyl

MS7061200

Pool Light Operation

WARNING: DO NOT operate the underwater light unless the unit is completely submerged

in water, otherwise damage will result and warranty voided.

Be sure on completion of the installation that your electrician checks all electrical

connections. Your electrician should also check and verify the voltage supply on the

primary and secondary side of the transformer.

To ensure maximum performance and benefit from your new Compact Series Underwater

light, we recommend that the light be used on a regular basis, i.e. a minimum usage of

once a week. More frequent use will prevent “tracking”, thereby providing longer lamp life.

To ensure a longer lamp life, do not operate the light for short periods.

Maintenance

Lamp Globe Replacement. –

Type

Globe Model

Number

Volts

C100

MS2575400

12

C150

MS2575500

28-32

Unscrew the stainless steel screw at the top of the mounting skirt.

Insert screwdriver blade into the top slot and twist. Unit can then be removed by unwinding

the cable from the special retaining brackets mounted on the rear of the light. Remove rear

reflector plate and unscrew old lamp.

NOTE: Care should be taken when fitting new lamp to avoid direct hand contact with the

glass component. If accidentally touched, clean with Methylated spirit before re-assembly.

Replace lamp, ensuring that the broad face of the filament faces outwards. If the unit has

been in service for more than 12 months we recommend that the lens “O” ring seal should

also be replaced when replacing the globe.

Replace the reflector plate making certain that the lamp is in a vertical position relative to

the lens and top of the face ring.

Replace nuts on screws and tension until finger tight. Final tensioning is on a diagonally

opposite method to ensure even pressure. DO NOT over tighten. The return edge on the

reflector plate should just contact the bosses on the rear of the face ring.