Davey PowerMaster 200, 250, 350, 450 (INCLUDING 415V 3 PHASE MODEL) User Manual

Page 2

– 6 –

Water Quality

Maintaining balanced water chemistry is important to the life of your pool pump. This

pump is designed to be used with Pool & Spa water, balanced in accordance with

Langlier Saturation Index, with a pH level of between 7.2 and 7.8 and is regularly

treated with a chlorine sanitising agent with the level not exceeding 3000PPM.

Please consult your local pool shop regularly to have your water tested.

Three Phase Power Connection

Three phase models are designed for connection to a nominal 415V power supply,

but must be wired with a contactor with ‘quick-trip’ overloads set at 4.3 amps.

Davey recommend the use of overloads which also have the ability to detect “single

phasing” or “dropped phase” conditions in the power supply.

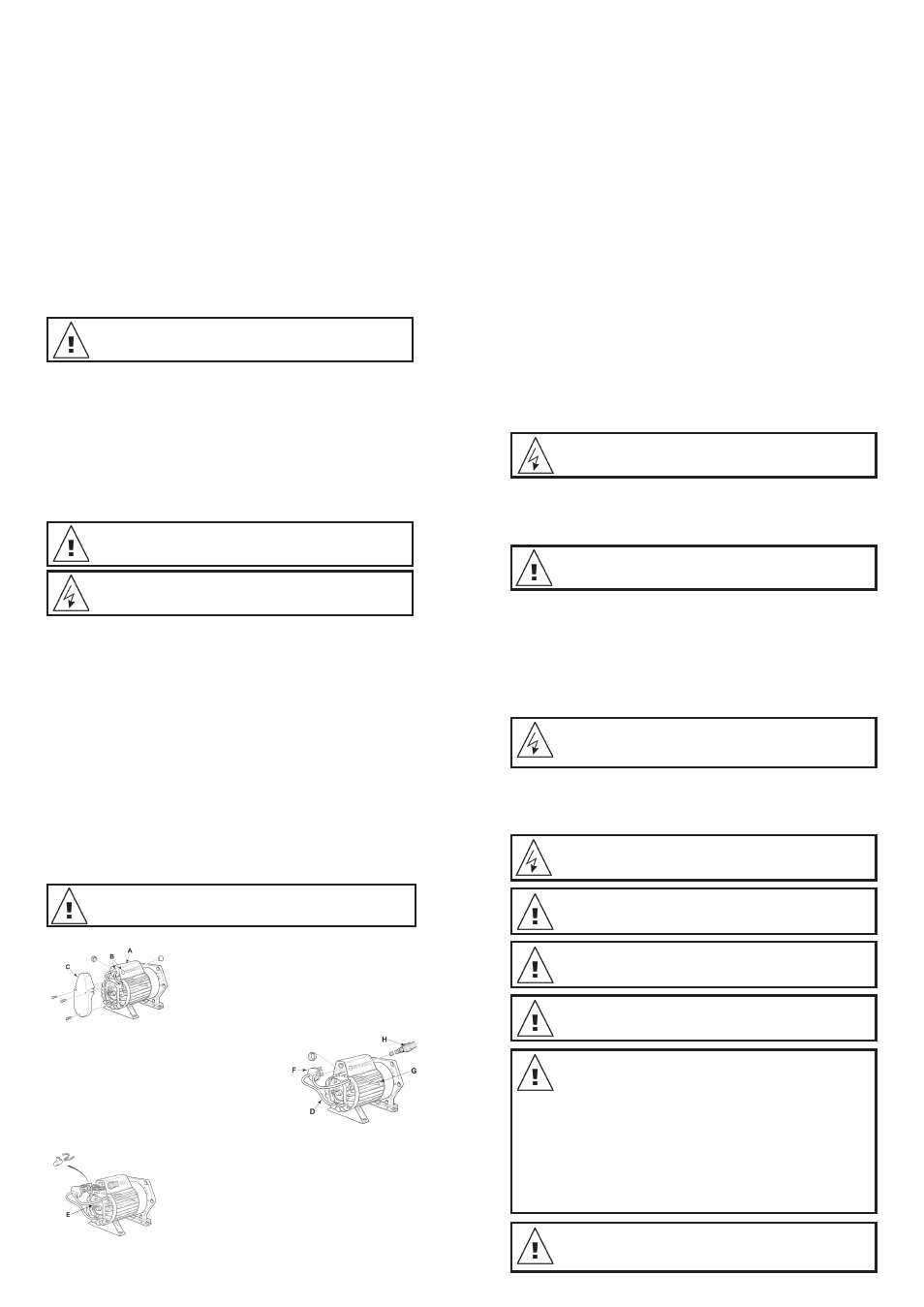

Three phase PM450 models have been designed to allow for connection either side

of the capacitor cover (marked “A” in figure one) on the motor.

This is achieved by way of either of the two 19mm

access holes (marked “B” in figure one). The

access holes are designed to accept most standard

cable grommets. The unused hole can be sealed

by inserting the plug enclosed with the pump.

To connect a three phase PM450 pump start by

removing the terminal cover (“C”)

Insert the blanking grommet (“F”) into the capacitor

cover (“A”). Fix the short lead (“D”) into the path

provided in the non-drive end-shield and replace the

terminal cover (“C”).

A short four core flex (“D”) is fitted from the motor

terminals (“E”). This lead is inserted through the

blanking grommet (“F”). Pressure switch or other

control leads (“G”) can be fitted as well. Incoming

power (“H”) can be fitted through the preferred access

hole, and terminated as shown in Figure Three. A

termination kit is available if required.

– 4 –

Starting the Pump

To operate efficiently and prevent pump damage there must be a free flow of water

to and from the pump. Before starting ensure that:

- all pipework is correctly sealed.

- the pool/spa water level is at the correct height.

- that all appropriate valves are open and there is nothing preventing the flow

of water through the system.

1. First prime the pump by removing the strainer basket lid and filling the strainer

basket area with water. Replace the lid, ensuring that it seals on the large oring.

2. Connect to the power supply and switch on.

3. Allow the pump to run, so that any air trapped may be expelled.

4. If prime is not established within approximately two minutes, as evidenced by a

strong flow of water, switch off the pump and repeat the procedure. Continued

evidence of air under the strainer basket lid indicates an air leak in the suction

piping which should be rectified to avoid pump damage.

Pump operation

For optimum pump performance, the strainer basket housing should always be full

of water and free from air bubbles. The water level of the pool should always be

maintained to at least halfway up the skimmer box ensuring water is in the pump at

all times. From time to time it may be necessary to re-prime the pump. This should

be carried out as described above.

Emptying the Strainer Basket

The strainer basket should be inspected frequently through the transparent lid

and emptied when a build up of rubbish is evident. The directions below should be

followed.

1. Switch off pump.

2. Unscrew the strainer basket lid anti-clockwise and remove.

3. Remove the strainer basket by lifting upwards from its housing.

4. Empty the trapped refuse from the basket. Hose out with water if necessary.

5. Check the strainer basket for cracks, replace the strainer basket in the pump if

OK.

6. Replace the lid and ensure that it seals on the large rubber oring.

Firm hand

tightness only is required. The oring & thread can be lubricated with Hydra

slip or equivalent products.

– 5 –

Trouble Shooting

If the pump runs but there is no water flow or water flow is reduced, the

following condition may apply:

1. The filter requires backwashing or it is blocked. Refer to the relevant section in

the Filter Manual.

2. The pump is not primed. Re-prime as per instruction in ‘Starting the pump’

3. There are air leaks in the suction piping. Check all piping and eliminate leaks,

also check for a loose strainer basket lid. Air bubbles in the water flowing back

to the pool would indicate a leak in the suction to the pump allowing air to enter

the pipework.

4. A leaking pump shaft seal may also prevent operating. Evidence of this would

be water on the ground under the pump.

5. The pump is not able to get water from the pool. Check that the valves to the

pump are fully open and that the pool water level is up to the skimmer box.

6. Blockage in the piping or pump. Remove the strainer basket and check for any

blockage to the pump impeller entry. Check the skimmer box for blockage.

If the pump does not operate, the following conditions may apply:

1. The power is not connected. For 240 volt only, check the power point by

plugging in a portable appliance to ensure power is available. Also check fuses

and the main power supply switch

2. Automatic overload is tripped. The pump has an in-built thermal overload which

will re-set automatically after the motor has cooled following an overheating

period. Determine the cause of the overload tripping and rectify.

3. Blockage is preventing the pump from rotating.

4. Motor is burnt out - burning smell is evident. Replacement is required.

If you are unable to resolve any installation or operation difficulties with your Power

Master

®

, contact the supplier from whom the pump was purchased or your nearest

Authorised Davey Pool Equipment Service Centre. If any further assistance is

required, contact the Davey Customer Service Centre at the address indicated in

this manual.

Removal of the Pump from Pipework

Should it be necessary to remove the pump, follow these instructions:

1. Switch off the power and remove the plug from the power source.

2. Close the water valves on the pool return and the pump inlet pipework.

3. Remove the discharge & suction barrel unions taking care not to lose the

orings.

4. Move the pipework with the barrel unions attached until the pump can be

pulled clear.

– 7 –

When the unit is connected and operating the phase balance should be checked.

This should be within 5% variation. “Rolling” the leads may help to improve a small

unbalance, but major phase unbalance will usually be attributable to an input power

unbalance. This must be addressed before the pump is used.

NOTE: If the pump is wired into a time clock or another automatic

control, the wiring should be removed by a qualified electrician.

NOTE: When making any enquiries about your Power Master

®

be

certain to quote the model number from the nameplate located on

motor.

IMPORTANT NOTE:- THREE PHASE MODELS ONLY

BEFORE FINALISING WIRING CONNECTIONS, CHECK THAT THE MOTOR ROTATES

IN DIRECTION OF ARROW (CLOCKWISE WHEN THE SHAFT IS VIEWED FROM THE

WIRING CONNECTION END). TO ALTER ROTATION, CHANGE ANY TWO POWER

LEADS AT MOTOR TERMINALS.

POWER CONNECTIONS AND WIRING MUST BE CARRIED OUT BY AN

AUTHORISED ELECTRICIAN.

NOTE: Three phase motors do not have capacitors fitted in the capacitor

cover.

Figure One

Figure Two

Figure Three

Never run pump dry. Running the pump with no water may damage the

mechanical seals, causing leakage and flooding. Dry running damage and

associated damage is not covered under warranty.

Failure to undertake regular maintenance may cause damage not covered

by warranty.

DANGER - Hazardous suction. Do not block water entry into filtration

system with any part of your body as the pressure can trap hair or body

parts, causing severe injury or death. Do not block suction. Turn off

pump immediately if someone becomes trapped.

Caution! Do not add chemicals directly to the pool skimmer. Adding undi-

luted chemicals may damage pump and filter and void warranty.

Small children using the pool or spa must ALWAYS have close adult su-

pervision.

Routine Maintenance tasks – to maximise the life of your pool equipment

& personal safety, use this checklist once a week. Turn pump off first.

a. Make sure that any pressure gauges are in working condition and the oper-

ating pressure is within limits as specified on the product.

b. Make sure that each suction inlet, and main drain has a cover that is secure-

ly attached and in safe working condition.

c. Make sure that all skimmer covers are securely attached and in safe working

condition. These should be replaced every 3 to 4 years.

d. Remove any obstructions or debris from the main drain cover.

e. Ensure the skimmer baskets and the pump hair and lint pots are free of

leaves and debris at least once a week.

f. Remove obstructions and combustibles from around the pump motor.

g. Make sure all wiring connections are clean and that all wiring and electrical

equipment is in good condition. Damaged wiring must be repaired or re-

placed by a qualified electrician as soon as damage is discovered.

h. Check water balance and sanitiser levels at your local pool shop.

WARNING! Pump suction is hazardous and can trap and drown or disem-

bowel bathers. Do not block suction. Do not use or operate swimming

pools, spas or spa baths if a suction cover is broken, missing or loose.

Two suction covers and inlets must be provided into every pump to avoid

suction entrapment.

Power supply to this pump needs to be through an isolating transformer

on RCD, having a rated operating current not exceeding 30mA.