Operation, Maintenance, Impeller clearance adjustment – Davey MUKMOVA MANURE & TRASH PUMP User Manual

Page 3: Spare parts

Discharge Piping - The pump outlet is 2” BSP female and 2” or larger polythene piping or equivalent should be used,

particularly if sprinkler is to be operated.

Operation

When first installed the pump must be filled with water at the priming hole adjacent to pump outlet. A weighted flap valve

on the suction inlet retains the liquid within the pump for subsequent operation.

As this pump has excellent self priming characteristics, there is no need to fit a foot valve or fill the suction pipe.

An automatic float switch may be wired into the contactor coil to operate the pump.

Maintenance

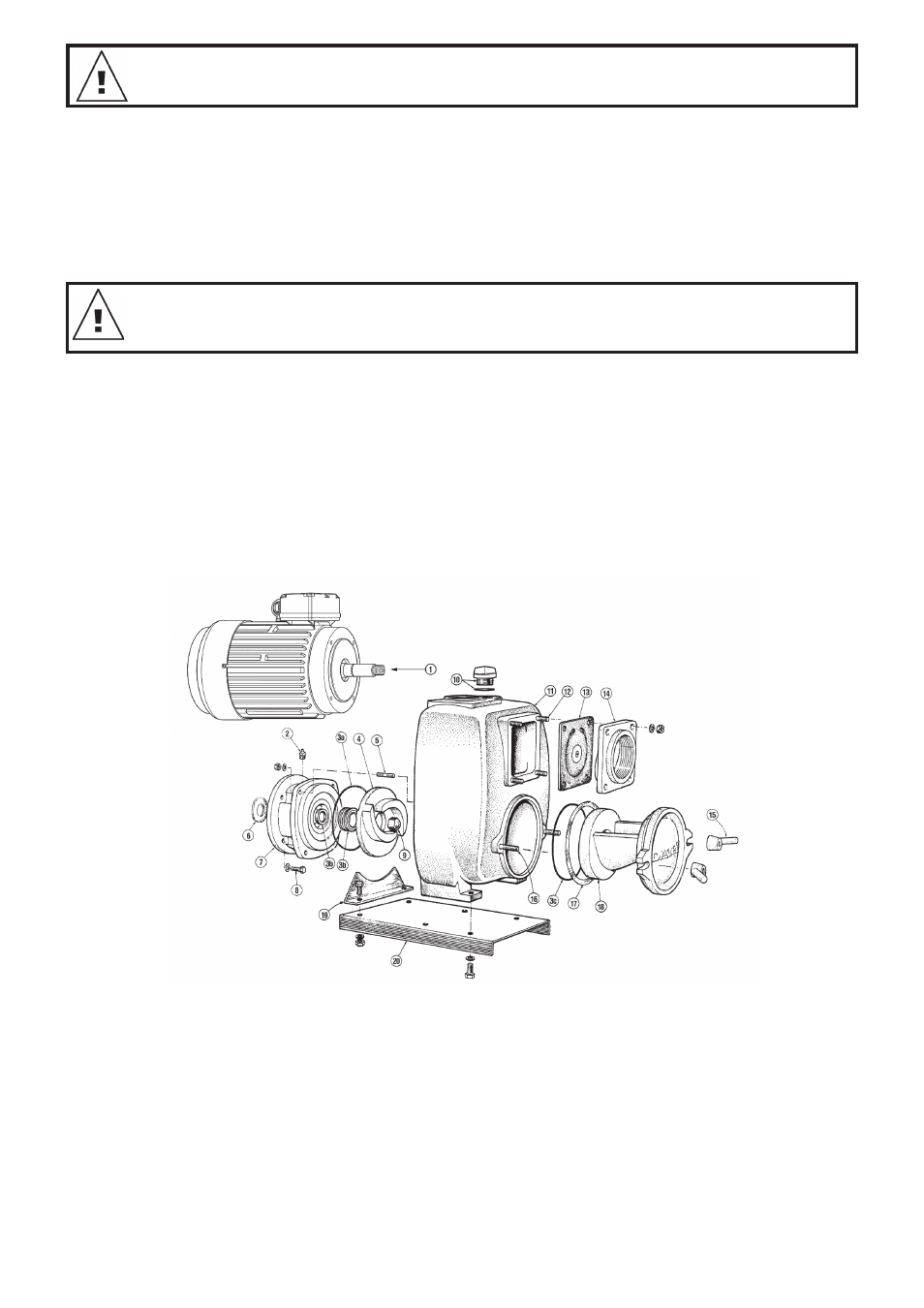

1. Monthly grease the seal area at the nipple (see exploded view - Item 2) located in the yoke (Item 7) joining pump

and motor. Use BP “ENERGREASE” multi purpose LS2 or equivalent.

2. Regular flushing of the pump with clean water is good practice when pumping dairy or piggery manure, and will

prevent build up and the need to unclog frequently.

3. If the pump has been idle for a long period, remove the inspection cover. (Item 18 located below the pump inlet),

and ensure pump impeller can rotate freely.

4. To clean any blockages, the large inspection hole provides excellent access to pump impeller area for cleaning.

Periodic cleaning out of the pump is good practice.

Impeller Clearance Adjustment

The Mukmova pump has an open face impeller (see the exploded view – Item 4). As this pump is used to pump manure

and “trash”, the impeller will wear over time.

The optimal performance of the pump is maintained by close fit of the inspection cover (Item 18) to the front of the

impeller. This close fit is maintained over the life of the pump by periodic removal of the impeller shims (Item 17).

When the pump is manufactured the correct number of shims will be inserted for peak performance. As this

performance declines over time, impeller shims will need to be removed to optimise the performance.

If all shims are removed and performance continues to decline, it is time to replace the impeller.

Spare Parts

Should any parts be required, be sure to quote Model and/or Build number from the nameplate on the pump.

NOTE: The use of suction piping smaller than 2

1

/

2

” I.D. will result in decreased pump performance. When

pumping dairy or piggery slurry, no inlet strainer should be fitted to the end of the suction hose as this may

easily be blocked.

The pump is capable of pumping up to 3/4” dia. solids in suspension, however pumping stones or hard

solids of any size for extended periods will shorten the pump’s life. A coarse screen should be installed

at the entrance to the collection pit to prevent large items including rocks, sticks and some straw from

entering.