Pressure switch, Adjustment – Davey 165S SHALLOW WELL PRESSURE PUMPS & SYSTEMS User Manual

Page 6

to check for correct operation as automatic pressure system

Close all outlet taps except one which should be turned on to allow small flow. Pump should build up pressure until it switches

off automatically at the cut-out pressure setting of the pressure switch (standard setting 380kPa, refer Table for others).

Pressure should then fall slowly as water flows from the one outlet tap until pump switches on automatically at cut- in setting of

pressure switch (standard setting 260kPa).

pressure switch

The pressure switch fitted to your Pressure Pump is required to function only if your pump is to operate automatically, in

conjunction with a Davey Supercell Pressure Tank.

adjustment

(if applicable)

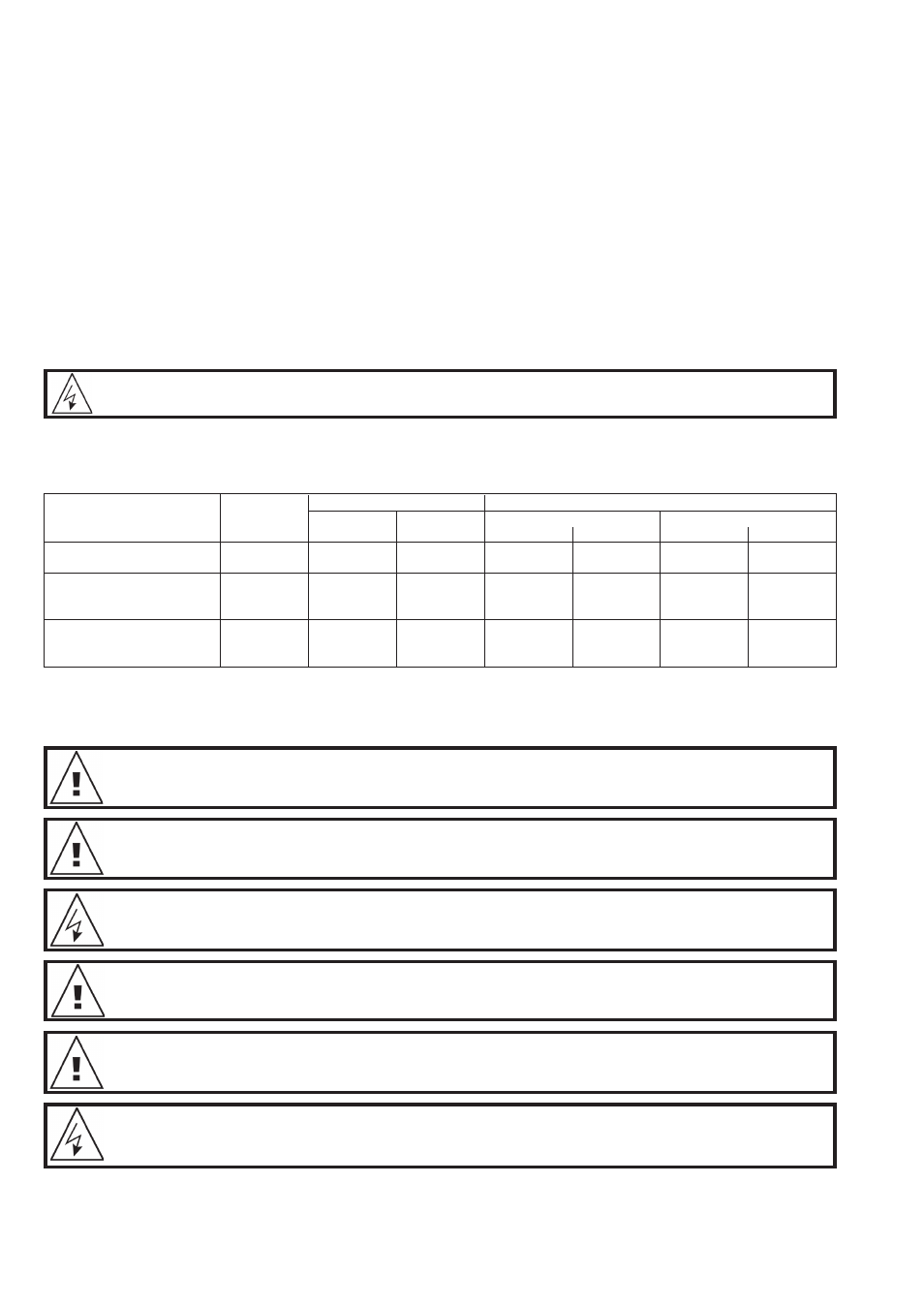

The standard operating pressure and respective pressure switch setting for each Model is denoted by an asterisk (*) in the

Table below. Performances at pressures higher than standard are obtainable by fitting alternative shallow well jet kits, and for

these installations it is necessary to reset the pressure switch according to the Table below. Instructions for altering the pressure

switch setting are under the cover of the switch itself.

pressure switch setting when installed as automatic pressure system

pressure system

pressure switch settings

Model Jet

kpa psi

kit

kpa

psi

cut-In cut-out cut-In cut-out

95S

690*

260*

38*

260

380*

38

55*

691 340 49 340 510 49 74

125S

693*

260*

38*

260

380*

38

55*

694 340 49 340 510 49 74

695 410 59 410 590 59 85

165S

697*

260*

38*

260

380*

38

55*

698 340 49 340 510 49 74

699 480 70 480 660 70 96

*Standard configuration. NB: ‘psi’ figures are an approximation of the kPa figures.

WarnIng: do not use hydrocarbon based or hydrocarbon propelled sprays around the electrical

components of this pump.

*NOTE: For protection, the Davey pump motor is fitted with an automatic reset thermal overload, constant

tripping of this overload indicates a problem e.g. low voltage at pump, excessive temperature (above 50°C)

in pump enclosure.

WarnIng: Automatic reset thermal overloads will allow the pump to restart without warning. Always

disconnect the pump motor from the electrical supply before maintenance or repairs.

IMportant:

DO NOT USE petroleum based fluids or solvents (e.g. Oils, Kerosene, Turpentine, Thinners,

etc) on the plastic pump components or seal components.

Care should also be taken when servicing or disassembling pump to avoid possible injury from hot pressurised

water. Unplug pump, relieve pressure by opening a tap on the discharge side of the pump and allow any hot

water in the pump to cool before attempting to dismantle.

WARNING: When servicing or attending pump, always ensure power is switched off and lead unplugged.

Electrical connections should be serviced only by qualified persons.

power connections and wiring must be carried out by an authorised electrician.

- 6 -