Introduction, Specifications, Inspection of pump – Davey ISOSPEC CF Series ISO2858 Heavy Duty Industrial Centrifugal Pump User Manual

Page 2: Driving options, Installation location, Foundations, Suction piping, Discharge piping

~ 2 ~

Introduction

Thank you for purchasing a quality Davey product. It

is our commitment to satisfy our customers by offering

our very best service.

This manual contains instruction for installation,

operation and maintenance of ISOspec

®

CF

bareshaft, single stage, non-self priming, centrifugal

pumps. Therefore, please read it carefully before use

to obtain a long satisfying service life of the purchased

unit.

Davey ISOspec

®

CF bareshaft centrifugal pumps are

designed with high efficiency and low maintenance

features.

Specifications

Model designation (example) :-

CF 200×150-500

Nominal dia. of impeller (mm)

Dia. of outlet (mm)

Dia. of inlet (mm)

Series code of pump

Inspection of Pump

Always check on receipt of delivery you have

received the correct pump unit. To identify, see above

specifications and label below. Check correct motor

kW & speed on motor nameplate (attached to motor)

prior to installation.

Driving Options

Your ISOspec

®

pump can be driven by a variety of

means. The best option is to direct drive via a suitable

coupling. If you must belt drive your ISOspec

®

pump,

lower speed (rpm). Limits may apply - see below:

Pump Size

Direct

Belt

50x32-160

3600 2900

65x50-160

3600 2900

80x65-160

3600 2900

100x80-160

3600 2850

50x32-200

3600 2900

65x40-200

3600 2900

80x50-200

3600 2900

100x65-200

3600 2250

125x100-200

3600 2060

65x40-250

3600 2480

80x50-250

3600 2050

100x65-250

3600 2180

125x100-250

3000 1620

150x125-250

2350 1440

65x40-315

3000 1800

80x50-315

3000 1800

100x65-315

3000 1450

125x100-315

3000 1380

150x125-315

2350 1420

200x150-315

1800 1150

250x200-315

1800 920

125x80-400

2350 1450

125x100-400

2350 1240

150x125-400

2350 1060

200x150-400

1800 920

125x100-500

1800 1240

150x125-500

1800 1060

200x150-500

1800 920

250x200-400

1800 920

Installation Location

It is important to select a site as close to the

liquid source as possible. When a suction lift is

unavoidable, install the pump as near to the water

level as possible (see suction piping). You should

always check the maximum permissible lift of the

pump from its performance curve.

Foundations

The pump unit should be mounted on a foundation

that is substantial enough to withstand the weight of

the unit & large enough to accommodate all mounting

feet so they can be securely fixed to avoid movement.

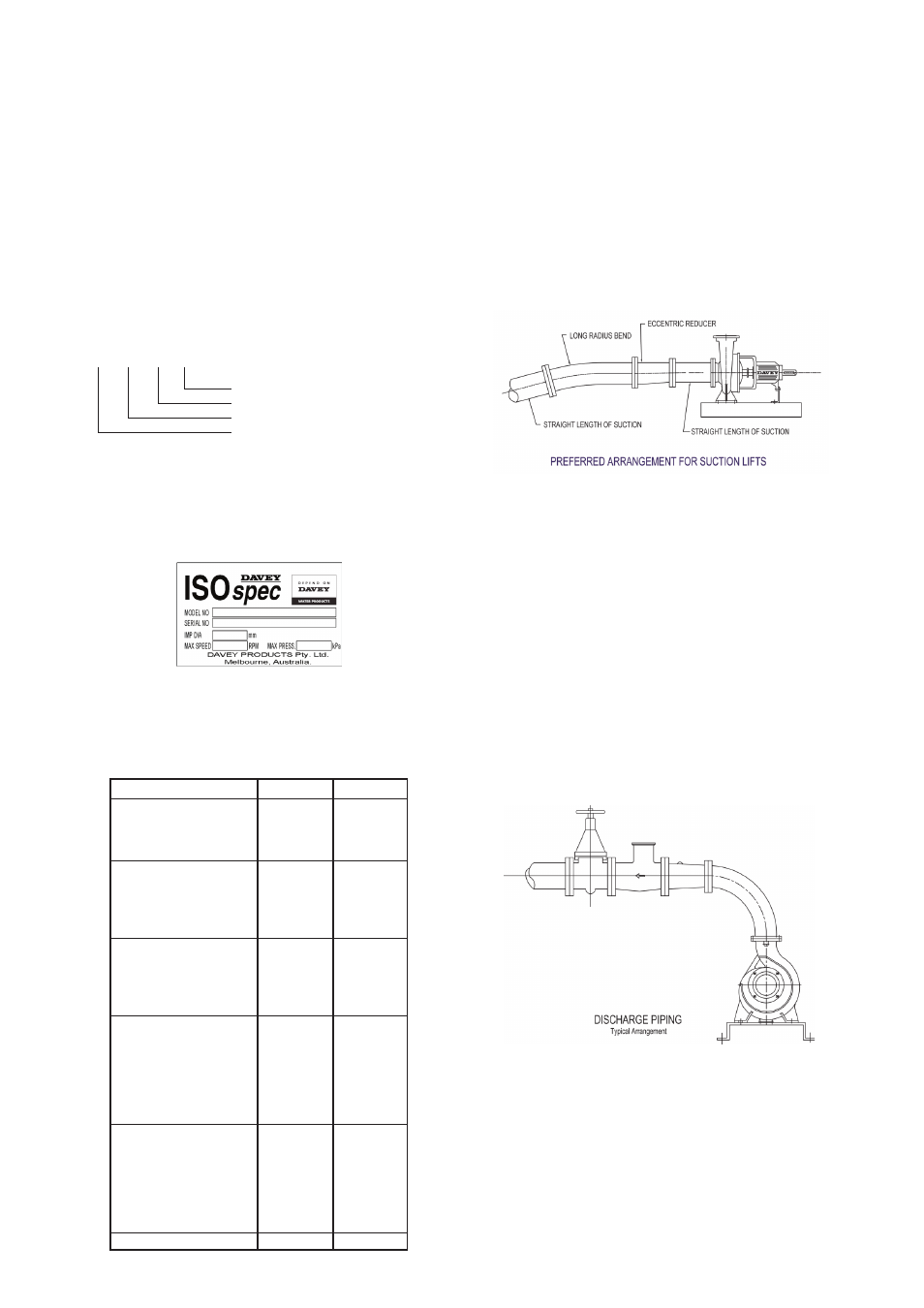

Suction Piping

All fittings & suction piping should be free of air leaks.

When a suction lift or long suction lengths are

unavoidable, consideration should be given to over

sizing the suction line to reduce suction losses. On

suction lifts a foot valve will be required, sized equal to

the suction line size. For applications on creek beds

or dams, please install a foot valve & strainer, well

submerged below the surface, to reduce whirlpools

& air inclusion. Air inclusion can result in cavitation

reducing the pump performance & eventually

destroying the pump or its components.

Long radius bends should be installed & a straight

length of piping equal to 2.5, the impeller diameter,

should be observed. Supporters should be equipped

to the inlet pipeline and outlet pipeline to avoid the

pump flange bearing too much tension force.

Discharge Piping

Discharge piping must be selected of a size that

would equal the discharge of the pump. For long

discharge lengths, consideration should be given to

oversize to minimize discharge losses reducing flow.

Talk to your nearest Davey dealer to calculate all

system losses. To avoid air pockets in discharge

lines at high points, vent cocks may be required to

release air blocks accumulated within the system. Air

pockets may affect the performance of the pump. A

throttling valve should be installed in the discharge

line to ensure the pump works within the performance

curve.