Application, Capacity, Features – Burcam 300526 1/2HP 115V EFFLUENT PUMP VERTICAL SWITCH C.I. /S. STEEL User Manual

Page 3: Installation steps

APPLICATION:

This submersible effluent pump is

designed for a permanent installation for

domestic use homes, cottages and farms.

Multi-purpose effluent pump will fill the

need in most sump applications.

To pump water as a permanent

installation pump.

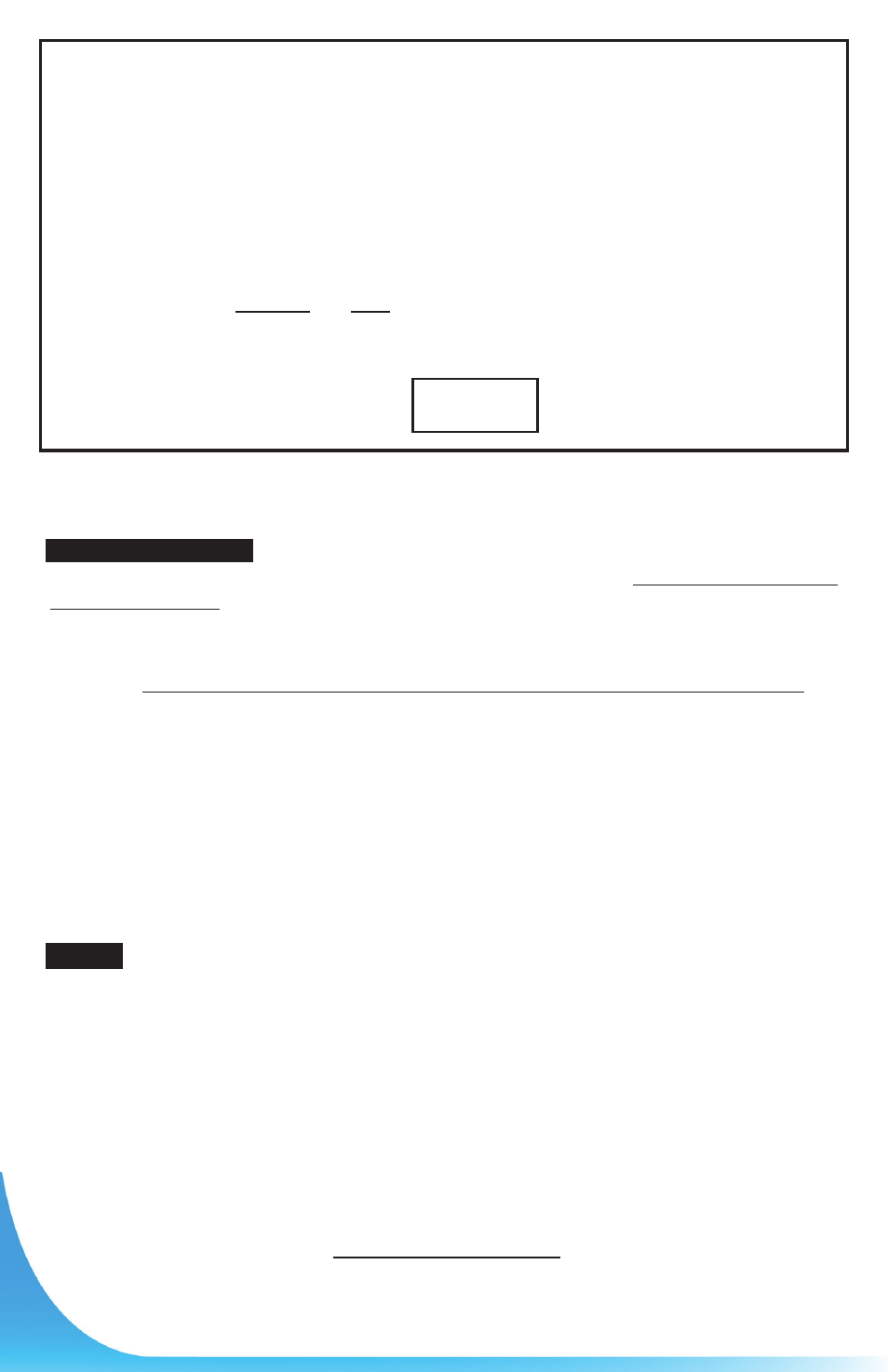

Capacity:

US GPH

LPH

5’ 4400 16600

10’ 3600 13600

15’ 2700 10200

20’ 2000 7550

25’ 600 2250

FEATURES:

Cast iron pump housing.

Stainless steel motor body.

Noryl vortex impeller, clog free type.

Piggyback grounded cables.

1/2HP, 115VAC, 60Hz, 5A (10A at start).

INSTALLATION STEPS:

IMPORTANT NOTICE

: Please note before you proceed with the installation of this

product that the manufacturer’s guideline has to be respected. Failure to comply may

void your warranty.

The following are minimum requirements in order to protect your residence from flooding.

It is a small investment but it is your personal responsibility to protect your home, family and

valuables. Failure to comply with the following requirements may also void your warranty:

- Two (2) pumps have to be installed in the sump pit. The first pump as a primary pump

and the second pump as the backup unit.

- Burcam alarm system model 450454 has to be installed to advise you of any malfunctions.

- As sump pumps are electrically powered and activated so to prevent flooding, a Burcam

battery powered back up pump model 300403 has to be installed to evacuate the water.

Pump selection, proper and adequate installation are a must to comply with local

by-laws and need to be adhered to.

STEP 1

We recommand that you install your pump in a clean location where there

is adequate room for servicing at a later date. Protection from freezing

temperatures and good ventilation should be considered as well, to provide

the pump an environment for long life.

Do not use to pump gas or toxic

fuels. This submersible sump pump is designed to pump water only.

Friction losses in the discharge pipe must be taken into consideration when

the horizontal offset is greater than 50 feet. The discharge pipe should be

increased from 1 1/2” to 2”. This will reduce friction losses and allow the

pump to give maximum performance. More friction losses must also be

taken into consideration when many elbows and fittings are installed in the

discharge line. Each elbows and fittings must be considered as 1 feet of head.

The float switch of your pump has been pre-set at the factory and does not

need any adjustment.

Never run the pump dry. Damage to the seal may occur.

Fill pump pit or sump basin with water before turning on the power.

Friction loss

not included.