Installation steps, Step 1 important notice step 2 step 3 – Burcam 300530 THERMOPLASTIC BASE COLUMN SUMP PUMP 1/3HP 115V User Manual

Page 2

Material required for

sump pump application

• Desired length of 1 1/2” ABS pipe.

• Elbows and fittings to run discharge pipe.

• ABS cimentz

• 1 1 1/2” ABS coupling to connect the pipe

to the check valve.

• 1 vertical check valve (350353).

APPLICATION

• This domestic sump pump is suitable for application where the

total vertical distance (head) does not exceed 15’. It is designed

as an economic and efficient means of protecting homes

agains water damage through seepage, where there is no natural

drainage.

• Capacity: 3000 GPH/ 5’ 2400GPH/10’ 1500GPH/15’

Locate the rod, the float and the rubber washers in the pump carton. Secure rod’s quide to pump’s

column. Push the rod through the rod guide, then push a rubber washer about six inches from top rod

end. Insert rod end through the top mount switch opening and place the second rubber washer over the

top rod end. Thread the float into the bottom rod end about six to eight turns. Depth of pumping level may

be adjusted by changing the position of the lower rubber rod washer.

Install the required (350353) check valve in the 1 1/4” discharge of the pump’s base. Thread in tightly.

Using 1 1/2” ABS coupling and ABS pipes, connect the discharge line to the check valve, and run it to the

desired waste location throught the basement wall of your house. Otherwise, drain hose kits are available

(350354). You may also connect a kit to the check valve with a clamp and run the pipe to the same

location. Be advised that restriction in these kits is important and increase the head of the discharge line.

Position the sump pump in centre of the sump pit (18” diameter X 25” deep). Plug the pump motor three

prong plug/cord into a grounded electrical outlet. Fill the sump pit with water to check pump operation.

Pump should start automatically when the switch lever is activated by the rubber washer and stop when

the water has been discharged and the float returns to the bottom of the sump pit.

Please note before you proceed with the installation of this product that the manufacturer’s

guideline

has to be respected. Failure to comply may void your warranty.

The following are minimum requirements in order to protect your residence from flooding. It is a small investment but it is

your personal responsibility to protect your home, family and valuables. Failure to comply with the following requirements

may also void your warranty:

• Two (2) pumps

have to be installed in the sump pit. The first pump as a primary pump and the second pump as the

backup unit.

• Burcam alarm system model 450454

has to be installed to advise you of any malfunctions.

• As sump pumps are electrically powered and activated so to prevent flooding, a Burcam battery powered back up pump

model 300403

has to be installed to evacuate the water.

Pump selection, proper and adequate installation are a must to comply with local by-laws and need to be adhered to.

STEP 1

IMPORTANT NOTICE

STEP 2

STEP 3

FRICTION LOSS IN PIPE NOT INCLUDED

NOTICE

This unit is not designed for applications involving salt

water or brine. Use with salt water or brine will void

warranty.

This product has been designed as a

dewatering pump for flood protection in a

residential home. The application of this

product is for permanent installation. Do not

use this pump to pump liquids (water)

in excess of 100 degrees F.

To the end consumer

If you have any problems with the product, before

advising the store, where you’ve purchased the pump,

please contact us at 514 337-4415 , and ask for our

sales department, and they will be pleased to help you

with any questions you might have, concerning your

installation.

INSTALLATION STEPS

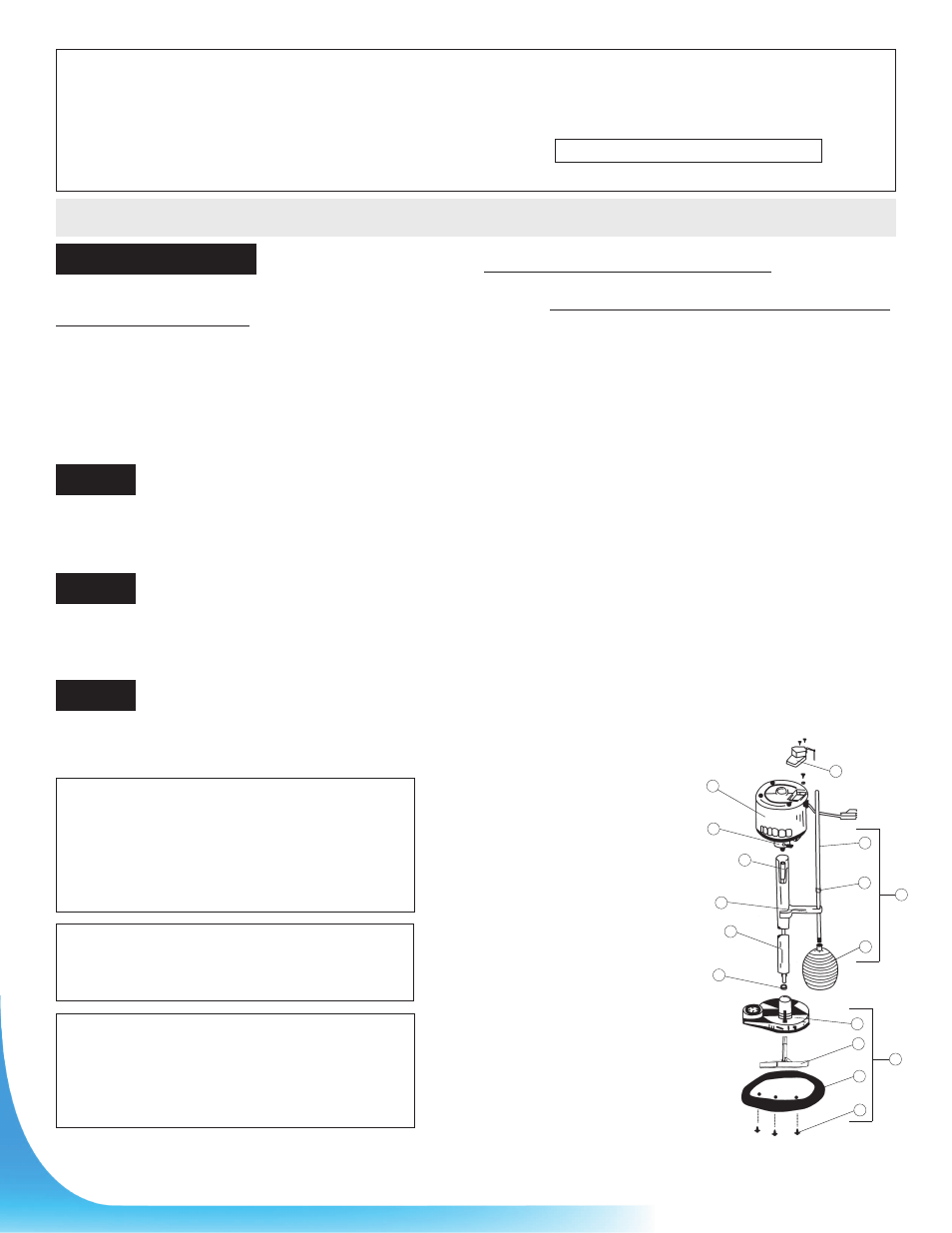

REPAIR PARTS

REF. PART

DESCRIPTION

1

350445

Top mount switch

2

350350A 1/3 HP 115V motor

3

350453

PVC main shaft with coupling

4

350450

Float rod

5

350447

Rubber stop (2)

6

350449

Float

7

350443

Float guide

8

350444

PVC column

9

350200

Volute suction

10

350202

Impeller

11

350201

Round base plate

12

350460

Base plate screws (12)

13

350446.1 Float/rod assembly

14

350468

Base assembly

15

350456

Motor bolts (3)

16

350461

Snap ring

15

16

1

2

3

4

8

6

7

5

9

10

11

12

14

13