Installation steps, Maintenance, Step 1 step 2 step 3 step 4 – Burcam 300308P MINIVAC UTILITY PUMP 115V 1/12HP C/W ACCESSORIES User Manual

Page 4

INSTALLATION STEPS

Fill liquid inlet and outlet of pump with one (1) table spoon of vegetable oil.

Install suction and discharge line

Plug cord into a 3 prong 115 VAC receptacle.

Unplug pump when liquid supply is exhausted. The overheat due to dry running will

damage impeller or weld it to the pump body.

STEP 1

STEP 2

STEP 3

STEP 4

MAINTENANCE

POUR INFORMATION TEL: 514.337.4415 FAX: 514.337.4029

4

❏ Verify for collapsed suction hose or plugged suction line

❏ Verify for liquid supply too far away or too far below pump (more than 20 feet)

❏ Worn out or damaged impeller

❏ Severe abrasive wear of volute plate or pump body. Remove pump cover to access these parts. Proceed

carefully to avoid damaging the “0” ring.

Spring

and brush

Cap

❏ The shaft motor seal is generally good for the life of the pump. When shaft seal leaks, it is because

enough abrasives have been pumped to wear deep grooves in the shaft under the seal. In this

situation, the purchase of a whole unit will cost less than repairs (motor and pump).

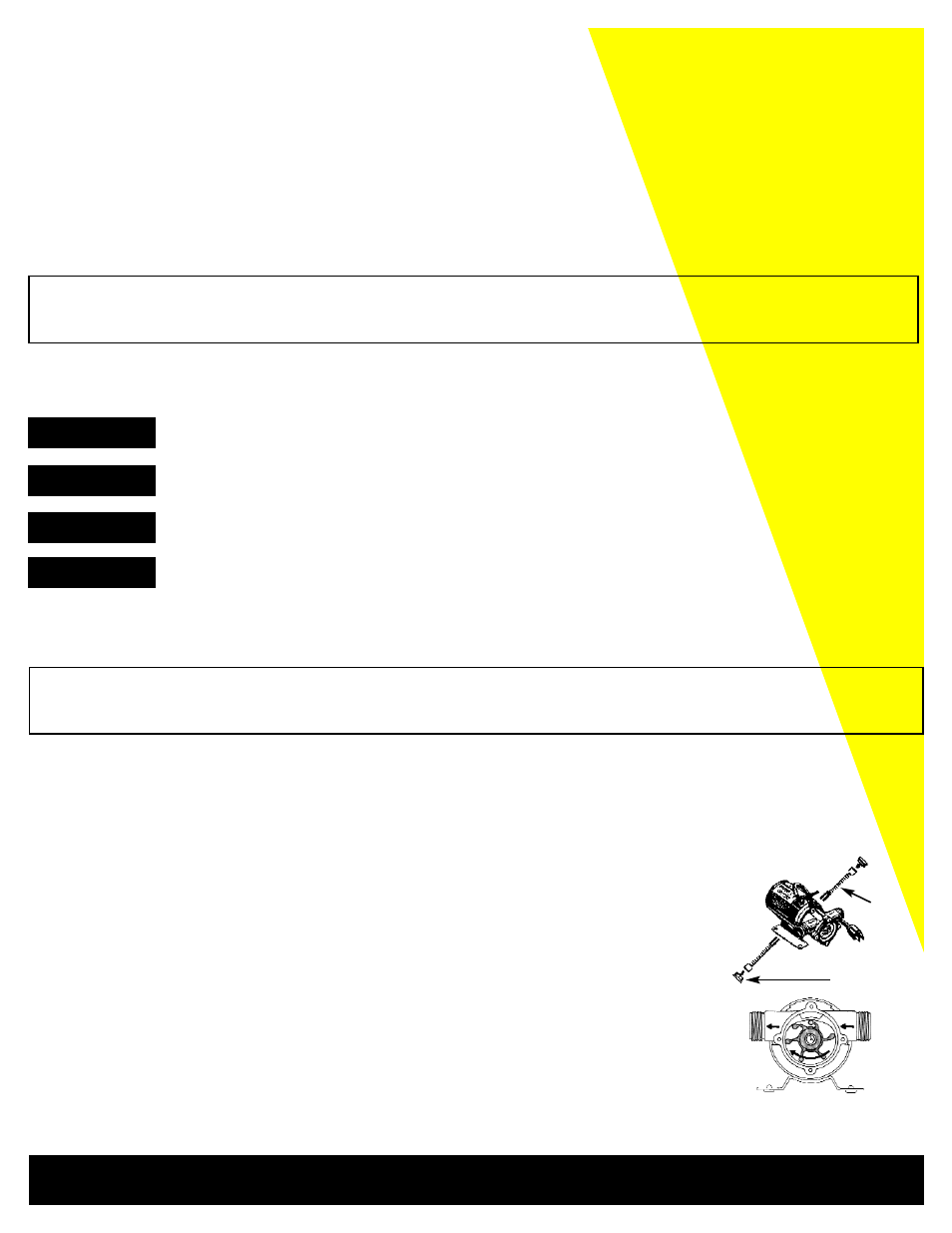

❏ Brush replacement is done quickly and easily. Unscrew brush cover, then

remove spring and worn brush. Insert the replacement brush and spring kit in

the same position and replace brush cover. Never drop oil in brush area. This

may damage the motor and void warranty.

❏ Impeller replacement is also easy to do. Remove pump cover screws and

cover. Remove worn impeller. Clean out inside of pump body and examine the

volute plate. If worn, turn over. Wipe a small quantity of oil and install the

replacement impeller by twisting in clockwise direction. This will blend the

blades in place. Using screws, replace pump cover. Do not overtight.