Watlow ind – Watlow FIREBAR Flange Heater User Manual

Page 3

WATLOW IND.

FIREBAR® Flange Heater Installation & Maintenance Manual

I&M NUMBER: 316-42-2-1

Page: 3

Date: 6/11/2008

Rev: 2.00

________________________________________________________________________________________________________________________________________________________________________________________________________________________

WATLOW IND.n # 6 INDUSTRIAL LOOP RD. n HANNIBAL MO, 63401n PHONE 573-221-2816 n FAX 573-221-3723

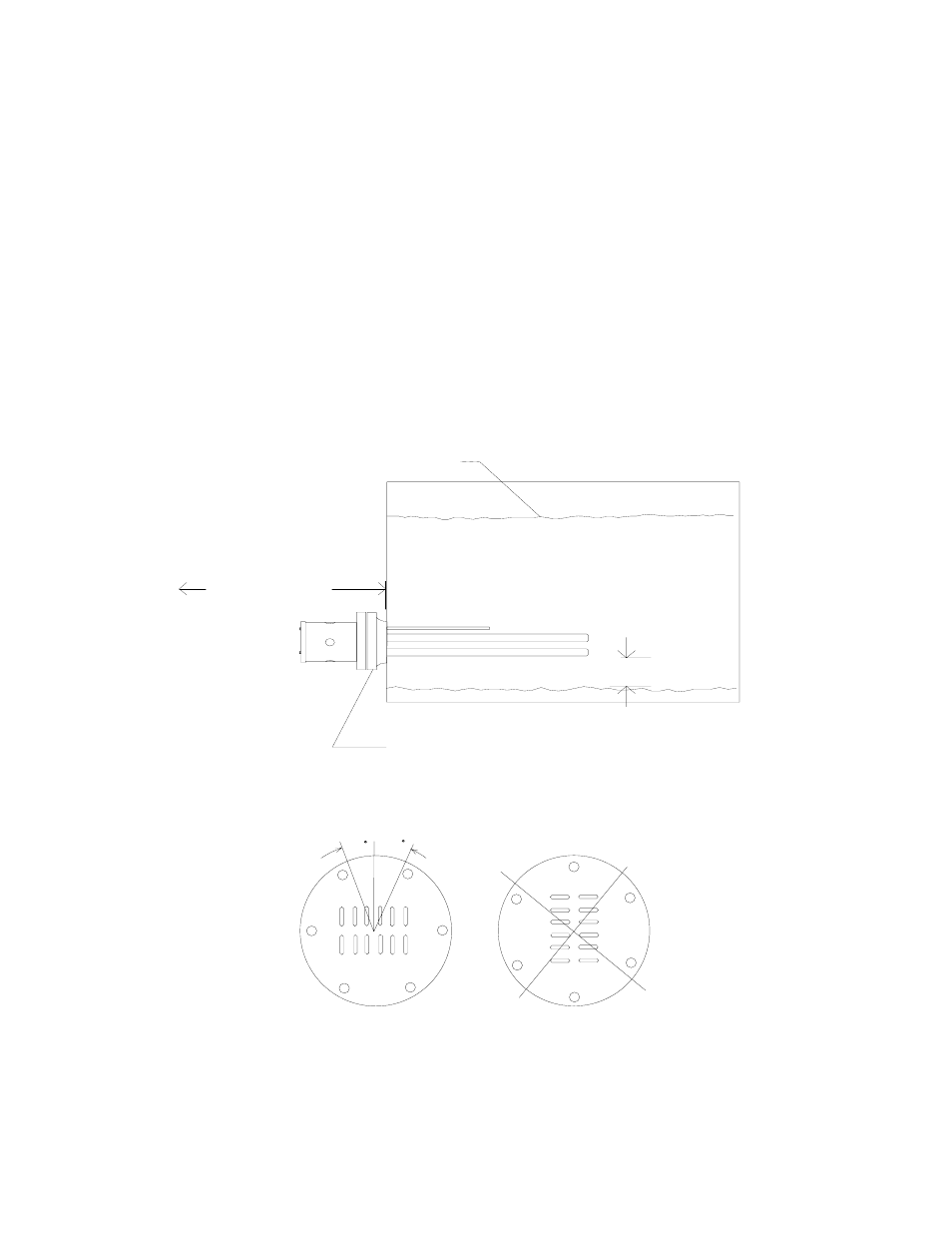

The recommended location for open tank heating is shown in Figure #1. The heater should be installed

as low as possible in the tank to take advantage of natural convection. Attention should be given to

sludge build-up and low liquid level. Location in either of these situations could cause premature failure.

During installation of the heater it is important that special attention be given to the final orientation of the

element. The flat side of the element must be positioned vertically as shown in Figure #2. Maximum

advantages are realized when the element is within +/- 25° of vertical. Positions outside this range are

not recommended, and 90° from vertical should always be avoided.

Each flange is marked with "TOP" to help clarify the preferred orientation. For open tank heating, this

marking should normally be on top of the final plug position. If this is not practical, it may be positioned

on the bottom, which will also orient the flat element vertical.

If heater is being installed in customer supplied circulation tank, a FIREBAR® Flange Circulation I&M

manual should be obtained from the factory to ensure safe installation of heater in tank. Failure to do this

could result in premature heater failure due to improper fluid flow over elements

SLUDGE

LIQUID LEVEL

2" MIN

ANSI WELD NECK FLANGE

TO MATCH HEATER FLANGE SIZE

HEATER REMOVAL

ALLOWANCE FOR

Figure # 1

25

25

TOP

TOP

CORRECT ORIENTATION

INCORRECT ORIENTATION

Remove terminal enclosure to see element position

Figure # 2