Trouble shooting guide – Versa-Matic N25 AIR OPERATED AIR OPERATED DOUBLE DIAPHRAGM PUMP User Manual

Page 5

HG-CF-998 Rev. D - 03/27/03

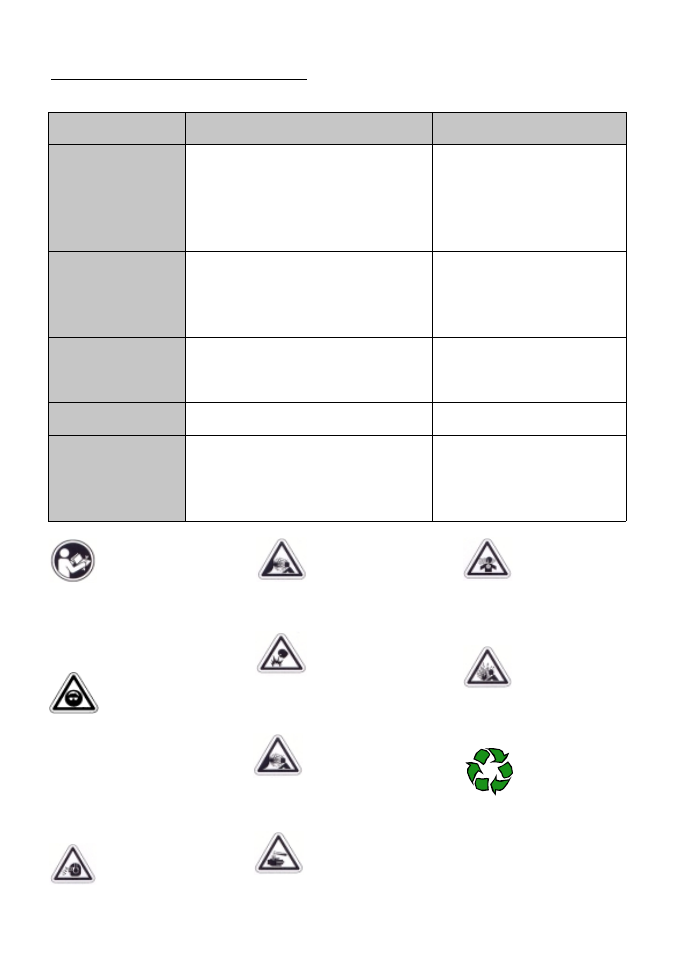

TROUBLE SHOOTING GUIDE

NOTE :- Check all solutions before dismantling the pump.

PROBLEM

CAUSE

SOLUTION

Pump will not start

Air valve assembly malfunction/Siezure

Obstructed fluid line.

Obstructed diaphragm chamber.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Air connected to exhaust.

Check carrier for freedom of movement. -

Clean, oil & replace.

Clean line or increase line size.

Remove obstruction.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Re-connect to air inlet.

Erratic flow

Diaphragm failure on one side.

Valve ball not seating.

Suction leakage.

Diaphragm failure causing fluid & excessive air to be

expelled through the exhaust.

Diaphragm seal failure.

Air valve system malfunction.

Replace diaphragm.

Check and remove obstruction.

Check and correct.

Replace diaphragm.

Replace shaft seals.

Check all seals in valve chest assembly.

Pump strokes but will not

discharge

Excessive suction lift.

Suction line leakage.

Valve ball not seating correctly or damaged.

Suction line or strainer clogged.

Diaphragm failure.

Shorten suction line.

Check and correct.

Check and remove obstruction / replace.

Clear.

Replace diaphragm.

Fluid discharged from air

exhaust

Diaphragm Failure.

Loose frontplate.

Replace diaphragm.

Re-Torque to manual specifications.

Intermittent stroke rate

Over lubrication

Diaphragm shaft seal failure.

Air valve system malfunction.

Valve ball not seating / partially obstructed.

Shut-down pump. Remove air connection

into pump & introduce a small quantity of de-

greasing agent into air valve and replace

line. Run pump until clear.

Replace seals.

Check all seals in valve chest assembly.

Clear obstruction.

Page 4

RECYCLING

Many components of KREMLIN

air operated double diaphragm

pumps are made of recyclable

materials. We encourage pump users to recycle

worn out parts and pumps whenever possible,

after any hazardous pumped fluids are

thoroughly flushed.

Read these safety warnings and

instructions in this manual

completely, before installation

and start-up of the pump. It is the responsibility

of the purchaser to retain this manual for

reference. Failure to comply with the

recommendations stated in this manual will

damage the pump, and void factory warranty.

WARNING!

Before maintenance or repair,

shut off the com-pressed air line,

bleed the pressure, and discon-

nect the air line from the pump. The discharge

line may be pressurized and must be bled of its

pressure.

WARNING!

In the event of diaphragm rup-

ture, pumped material may enter

the air end of the pump, and be

discharged into the atmosphere. If pumping a

product which is hazardous or toxic, the air

exhaust must be piped to an appropriate area for

safe disposition.

WARNING!

Before pump operation, inspect

all gasketed fasteners for loose-

ness caused by gasket creep. Re-

torque loose fasteners to prevent leakage. Follow

recommended torques stated in this manual.

CAUTION!

This pump is pressurized

internally with air pressure

during operation. Always make

certain that all bolting is in good condition and

that all of the correct bolting is reinstalled during

assembly.

IMPORTANT!

Take action to prevent static

sparking. Fire or explosion can

result, especially when handling

flammable liquids. The pump, piping, valves,

containers or other miscellaneous equipment

must be grounded.

WARNING!

Airborne particles and loud noise

hazards. Wear ear and eye protec-

tion.

WARNING!

When used for toxic or

aggressive fluids, the pump

should always be flushed clean

prior to disassembly.

WARNING!

Before doing any maintenance

on the pump, be certain all

pressure is completely vented

from the pump, suction, discharge, piping, and

all other openings and connections. Be certain

the air supply is locked out or made

non-operational, so that it cannot be started

while work is being done on the pump. Be

certain that approved eye protection and

protective clothing are worn all times in the

vicinity of the pump. Failure to follow these

recommendations may result in serious injury or

death.

WARNING!