Important – Versa-Matic SPA15-BSP3 Porta-Matic User Manual

Page 2

Model SPA15 and SPA15-BSP Design Level 3 Page 2

520-377-000 Rev C 8/02

TROUBLE SHOOTING

NOTE: Most common cause of failure to run is due to hardened mud and sand at

impeller. Remove strainer to check.

MOTOR WILL NOT RUN:

1. Poor connection at battery.

2. Impeller locked with foreign material.

3. Insufficient impeller clearance.

4. Damaged power cable or loose connection internally in motor assembly.

5. Bad switch or circuit breaker. Connect power leads direct to motor leads to check.

6. Worn motor brushes or out of position to make contact with armature.

PERFORMANCE LOW:

1. Strainer screen partially plugged.

2. Impeller rubbing. Check freeness of rotation with screwdriver inserted through

hole in base plated into slotted end of shaft.

3. Battery not fully charged.

4. Discharge restriction such as kinked hose or excessive discharge head.

Motor runs backwards:

1. Check wiring for correct polarity.

SERVICE AND REPAIR INSTRUCTION

DISASSEMBLY: Impeller and shaft seal can be inspected and serviced from

lower end of pump by removal of 4 capscrews securing base plate, strainer screen,

and suction cover. Screwdriver slot is provided in end of motor shaft to turn shaft while

holding impeller for removal. This permits removal of impeller without

disassembly of upper motor housing to hold motor shaft.

To service motor remove 4 hex nuts and bump top cover free from housing tube.

Raise sufficiently to disconnect power cable connections. Slide housing tube up from

pump casing and motor will be exposed for service or removal.

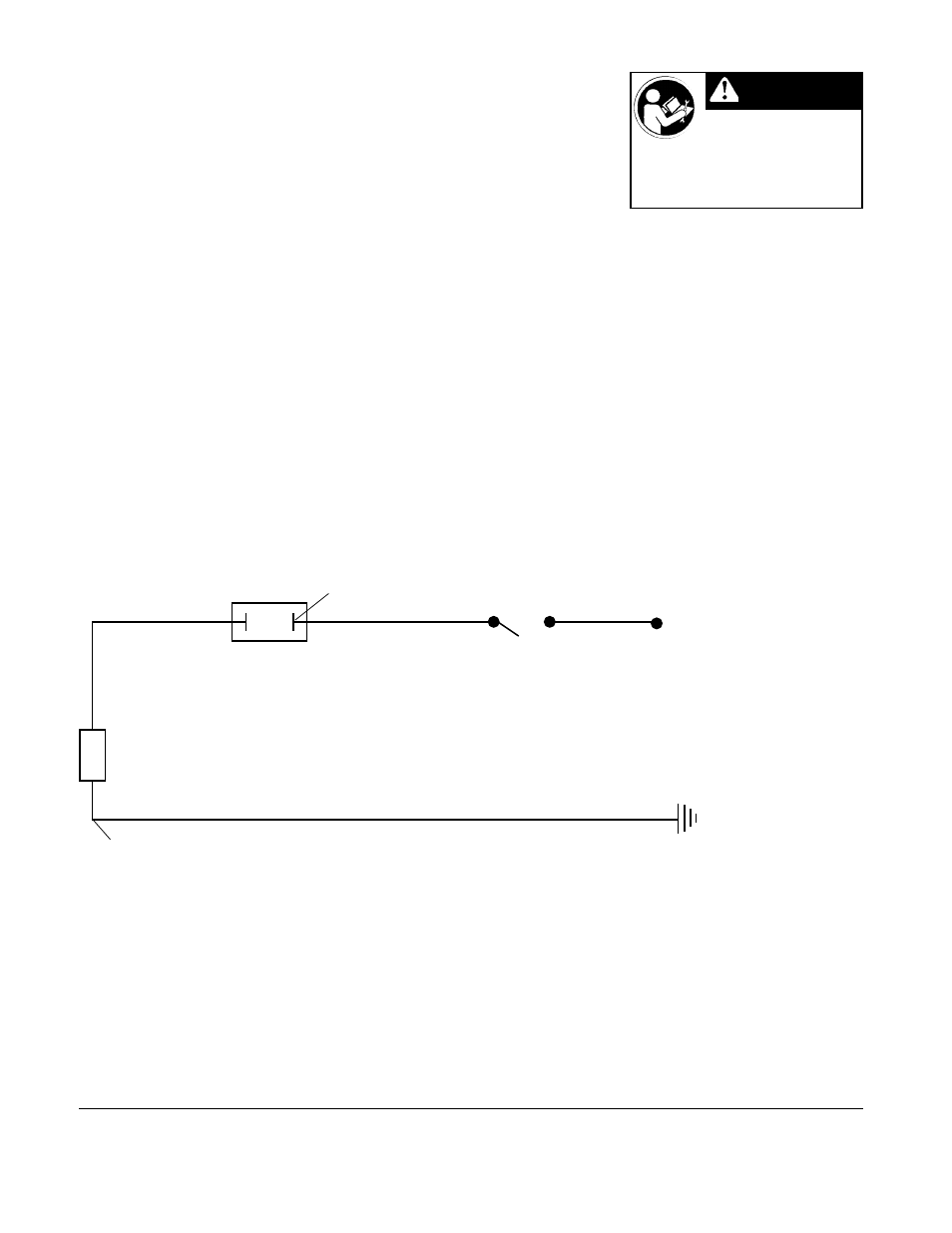

IMPORTANT: Make certain that wire leads are installed per diagram below.

Install top cover as indicated by arrow and instruction on top of cover.

WARRANTY

This unit is guaranteed for a period of 5 years against defective material and

workmanship.

©2002 Versa-Matic Pump All rights reserved.

Printed in U.S.A.

Red Battery

Clamp

Switch

Aux

Batt

Red

Motor

Black

Black Battery

Clamp

(Ground)

Circuit Breaker

510-003-000 Compression Lug

240-001-000 Twist Clamp

Should unit not operate,

always check freeness of

rotation of impeller by inserting

screwdriver through hole in base

plate into slot in end of shaft.

IMPORTANT