Floodsafe, Inflow preventer, Passed □ failed – Val-Matic 1-16 in. FloodSafe Inflow Preventer User Manual

Page 6

5

FloodSafe

®

Inflow Preventer

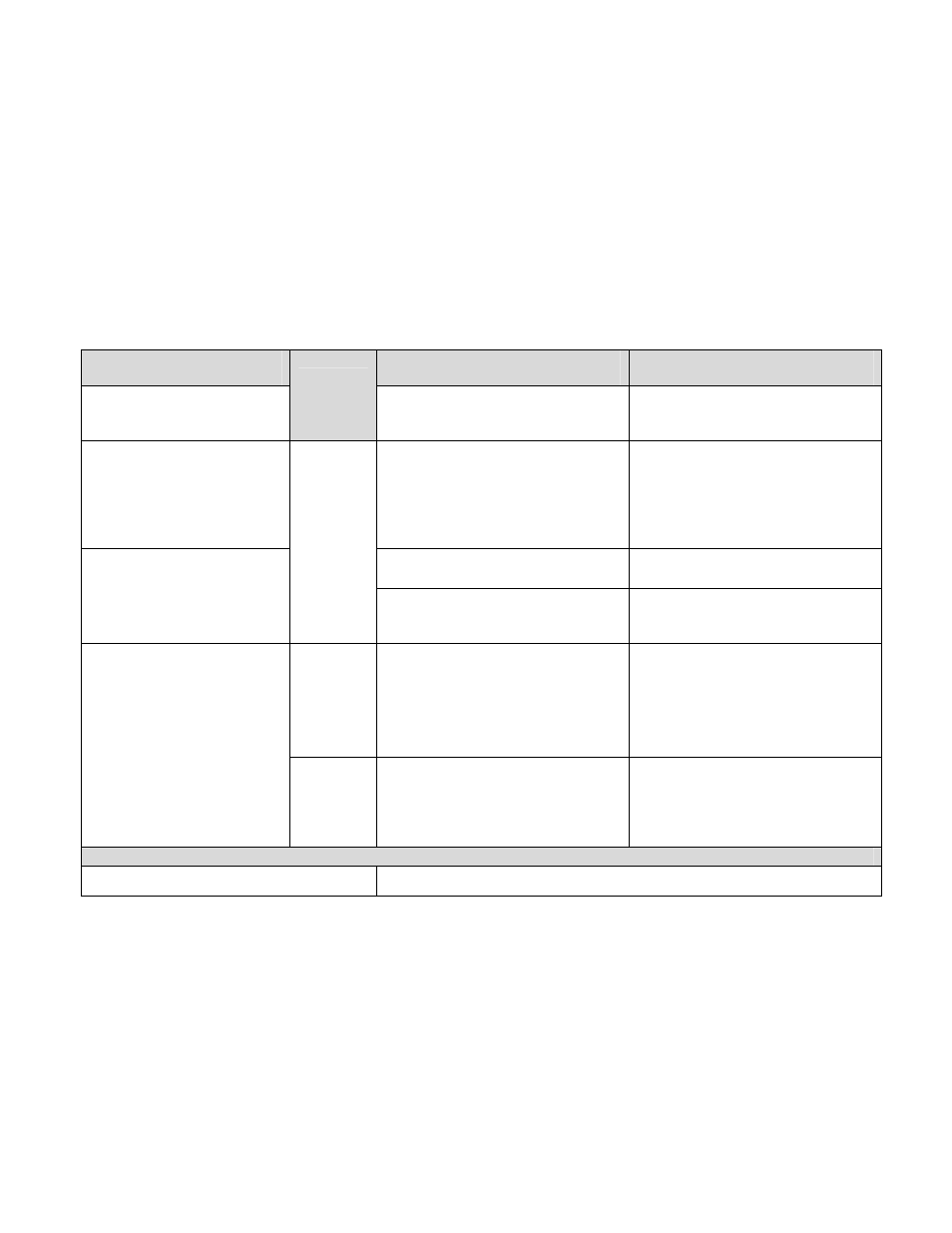

TEST AND MAINTENANCE REPORT

OWNER: _________________________________________________________________________________

ADDRESS: ________________________________________________________________________________

LOCATION OF ASSEMBLY: __________________________________________________________________

MANUFACTURER: _________________________ MODEL NO: ____________________________________

YEAR OF MANUFACTURE: _______________________ SIZE: ____________________________________

PROCEDURE: See “FIELD TESTING THE FLOODSAFE” in the Instruction Manual.

1. Isolation Valve

Under Air Valve

2. Inflow Preventer Test

Lower Chamber

3. Inflow Preventer Test

Upper Chamber

□ leaked or

□ closed off tight

□ test cocks OK or

□ test cocks replaced

□ open test cocks

□ test cock OK or

□ test cock replaced

Record any maintenance

performed:

Initial

Tests:

□ Connect test pipe assembly

to test cock A.

□ Fill lower chamber and test

pipe with clean water.

□ Maintain water level above

“Minimum Test Level”

□ Connect test pipe assembly

to test cock B.

□ Fill upper chamber and test

pipe with clean water.

□ Maintain water level above

“Minimum Test Level”

Inflow Preventer Basket

□ removed and cleaned

□ Observe test cock B for

leakage for 5 minutes.

□ Observe test cock C for

leakage for 5 minutes.

Any sign of leakage from test

cock is cause for rejection.

□ Pass □ Fail

Any sign of leakage from test

cock is cause for rejection.

□ Pass □ Fail

Bottom Plug

□ installed

Repairs:

Record maintenance

performed:

Record maintenance

performed:

Final

Tests

(when

needed):

If initial test failed, repeat 5

minute test. Any sign of

leakage from test cock B is

cause for rejection.

□ Pass □ Fail

If initial test failed, repeat 5

minute test. Any sign of

leakage from test cock C is

cause for rejection.

□ Pass □ Fail

IMPORTANT: □ After testing, reopen the isolation valve under the air valve.

NOTE: All repairs and final tests should be completed within five (5) working days.

COMMENTS: _______________________________________________________________________________

___________________________________________________________________________________________

I hereby certify that this data is accurate and reflects the proper maintenance of the assembly.

TESTER: _____________________________ CERT No. __________________ DATE: __________________

TIME: ___________________

THIS ASSEMBLY:

□ Passed □ Failed