Val-Matic 1-16 in. FloodSafe Inflow Preventer User Manual

Page 3

2

ITEM

DESCRIPTION MATERIAL

1A, 1B

Chamber

Ductile Iron

2

Cover

Ductile Iron

4A, 4B

Seat

Resilient

5A, 5B

Float Check

T316 Stainless Steel

7A, 7B

Bolts, Nuts

T316 Stainless Steel

8

Basket Retainer T316 Stainless Steel

12

Basket

T304 Stainless Steel

14

Pipe Plug

Carbon Steel

80*

Mounting Bracket Carbon Steel

80A*

Mounting Bolt T316 Stainless Steel

* Optional

INSTALLATION

Remove the packing from the top and bottom of

the FloodSafe

®

that is used to protect the floats

during shipping. Install the basket per step 6 in

the REASSEMBLY section on page 3. The

installation of the FloodSafe

®

is important for its

proper operation. The FloodSafe

®

should be

installed plumb in the vertical position with the

basket facing downward. Thread or bolt the

FloodSafe

®

to the outlet of an air valve using

standard connection practices. The bolting for 6"

and larger devices conforms to ANSI B16.1 for class

125# flanges. An optional mounting bracket (80)

may be used to mount the device to wall supports.

Flanged connections should only be mated with flat-

faced pipe flanges equipped with full-face or ring

type resilient gaskets. The bolts should be tightened

in gradual steps using the crossover method.

Recommended torque values are given in Table 1.

Table 1. Flange Bolt Torques

FLOODSAFE

®

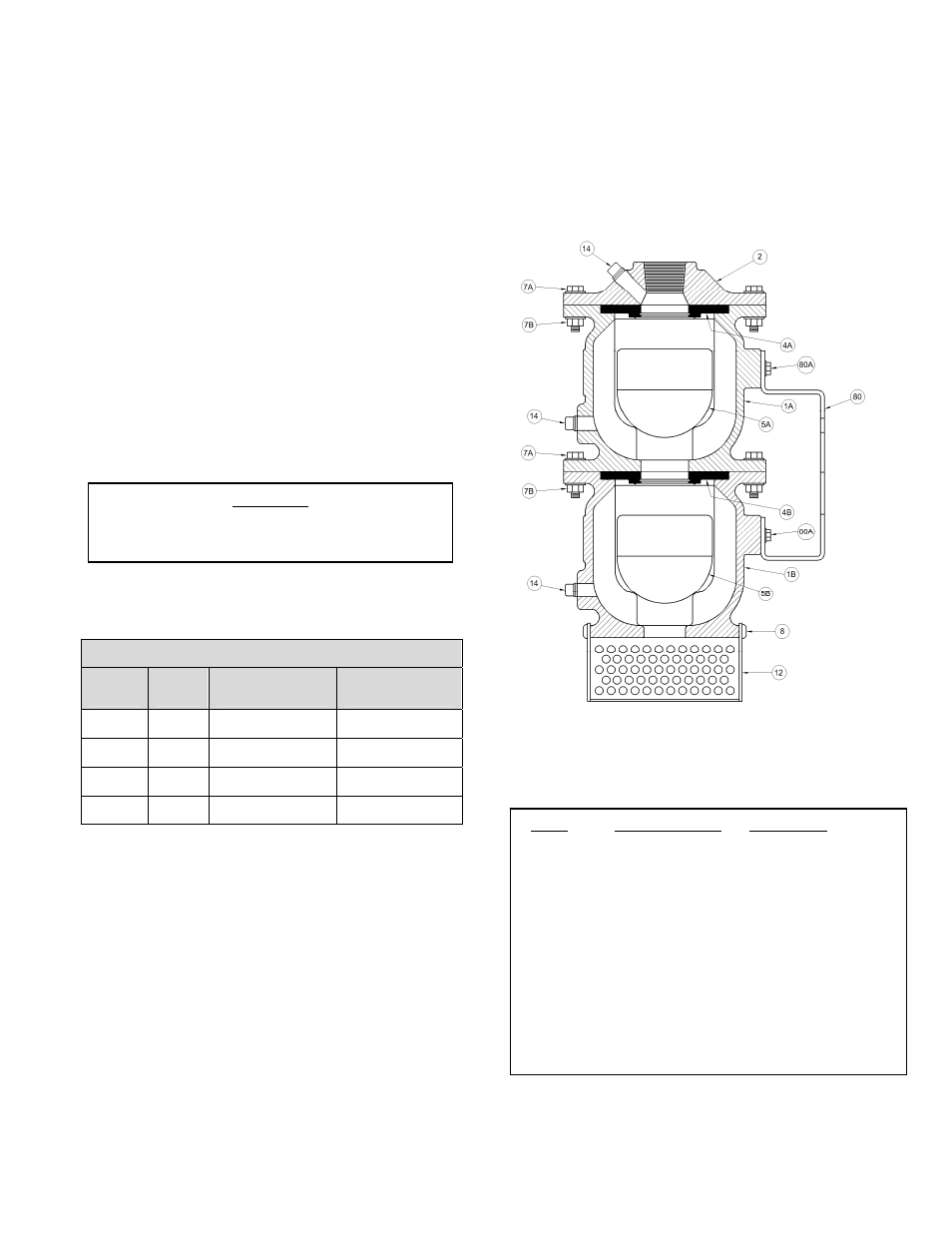

CONSTRUCTION

The standard FloodSafe

®

is constructed of ductile

iron. Stainless steel type 316 float checks are the

only moving elements and seal against a low

hardness resilient seat. The general details of

construction are illustrated in Figure 3 and identified

in Table 2.

Figure 3. FloodSafe

®

Components

Table 2. FloodSafe Parts List

Mounting Flange Bolts (ANSI B16.1 Class 125)

Device

Size

Bolt

Size

Recommended

Torque (ft-lbs)

Maximum

Torque (ft-lbs)

6 3/4"

30

150

8 3/4"

40

150

12 7/8”

45

200

16 1”

90

300

CAUTION:

The use of excessive bolt torque may damage

the device.