Valve construction, Maintenance – Val-Matic Wafer and Globe Style Silent Check Valve User Manual

Page 5

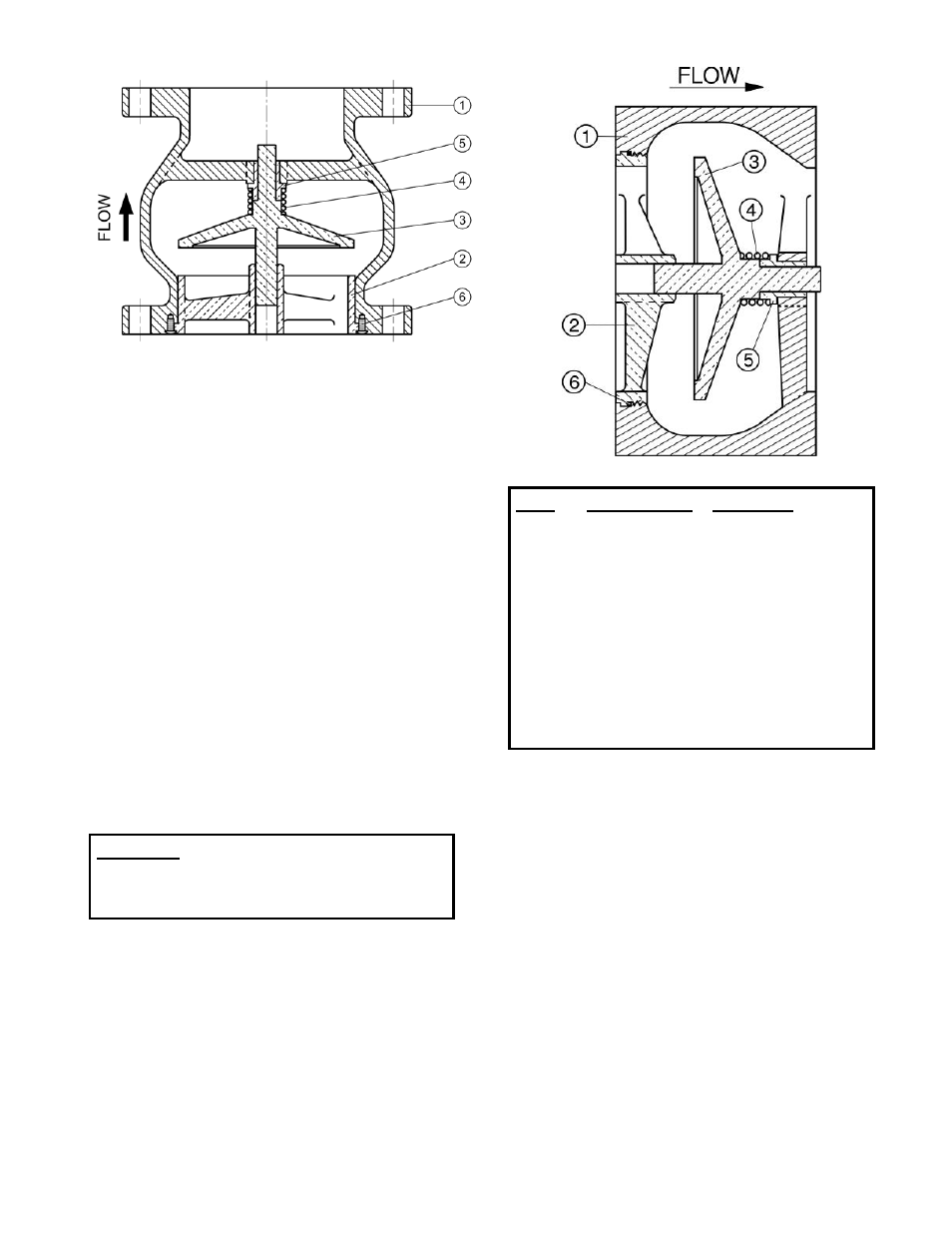

FIGURE 3. GLOBE STYLE CHECK VALVE

VALVE CONSTRUCTION

The standard check valve body (1) is constructed of

iron. See the specific Materials List submitted for

the order if other than standard iron construction.

The internal metal components are bronze or

stainless steel. The disc (3) and spring (4) are the

only moving parts and require no maintenance or

lubrication. The general details of construction are

illustrated in Figures 2 and 3.

The body (1) is either compact wafer style to fit

between two pipe flanges or flanged style for

connection to two pipe flanges. The globe style

valve seat (2) is retained in the body (1) with screws

(6) to allow assembly in the pipeline. The wafer

style valve seat and the 2-1/2” globe style seat are

threaded seats where no seat screws (6) are used.

The seat screws will not retain the seat against full

pressure. The mating flange must properly retain

the seat. Do not remove the upstream flange while

the pipeline is full of water or the seat (2) may

become dislodged from the body.

FIGURE 4. WAFER STYLE CHECK VALVE

TABLE 2. CHECK VALVE PARTS LIST

MAINTENANCE

Silent Check Valves require no scheduled lubrication

or maintenance.

INSPECTION: Periodic inspection for leakage can

be performed by listening for leakage noise from the

valve while the pump is shut down. If leakage is

heard, drain the pipeline, remove the valve, and

inspect the seating surfaces for wear or mineral

deposits. Clean, lap, or repair trim as needed.

WARNING: Removal of mating flanges

without draining the pipeline may

cause injury or damage to the

valve.

ITEM

DESCRIPTION

MATERIAL

1 Body

Cast

Iron

2 Seat

1

Bronze or SS

3 Disc

1

Bronze or SS

(Optional

Resilient)

4 Spring

1

Stainless

Steel

5 Bushing

1

Bronze

6

2

Screw

1

Stainless

Steel

6

3

O-Ring

1

EPDM

1. Recommended Spare Part

2. Globe style valve

3. Wafer style valve

4