Installation – Val-Matic 14 and Larger Wafer and Lug Style Dual Disc Check Valve User Manual

Page 3

INSTALLATION

The installation of the valve is important for its

proper operation. The flow arrow on the valve body

or nameplate must point in the direction of flow when

the system is in operation. The valve can be

installed in horizontal or vertical lines with the flow

up. Valves for air service (Series 8900) require

special springs to allow full valve opening.

The valve should be installed between standard

flanges per ANSI B16.1 or AWWA C207. The

gasket can be rubber or compressed fiber.

Three diameters of straight pipe upstream of the

valve are recommended to prevent turbulent flow

streams through the valve, which can cause

vibration and wear.

When mating the check valve with butterfly isolation

valves, the isolation valve must be installed at least

one diameter downstream of the check valve. The

check valve discs extend beyond the downstream

flange face and may interfere with the operation of

adjacent valves. A short run of pipe or spacer is

needed between the check valve and the isolation

valve.

2

LUG WAFER ENDS: Lug wafer valves should be

mated with flat-faced pipe flanges equipped with

resilient gaskets.

WAFER ENDS: Wafer valves should be mated with

flat-faced pipe flanges equipped with resilient ring

gaskets and full length studs.

INSTALLATION: Lower valve between mating

flange using slings or chains around the valve body.

The valves have a tapped hole for insertion of a

lifting eye if needed. Lubricate the flange bolts or

studs and insert them around the flange. Lightly turn

bolts or nuts until gaps are eliminated. The

tightening of the bolts should then be done in

graduated steps using the cross-over tightening

method. Recommended lubricated torques for use

with resilient gaskets (75 durometer) are given in

Table 1.

If leakage occurs, allow gaskets to absorb fluid and

check torque and leakage after 24 hours. Do not

exceed bolt rating or crush gasket more than 50 per

cent of its thickness.

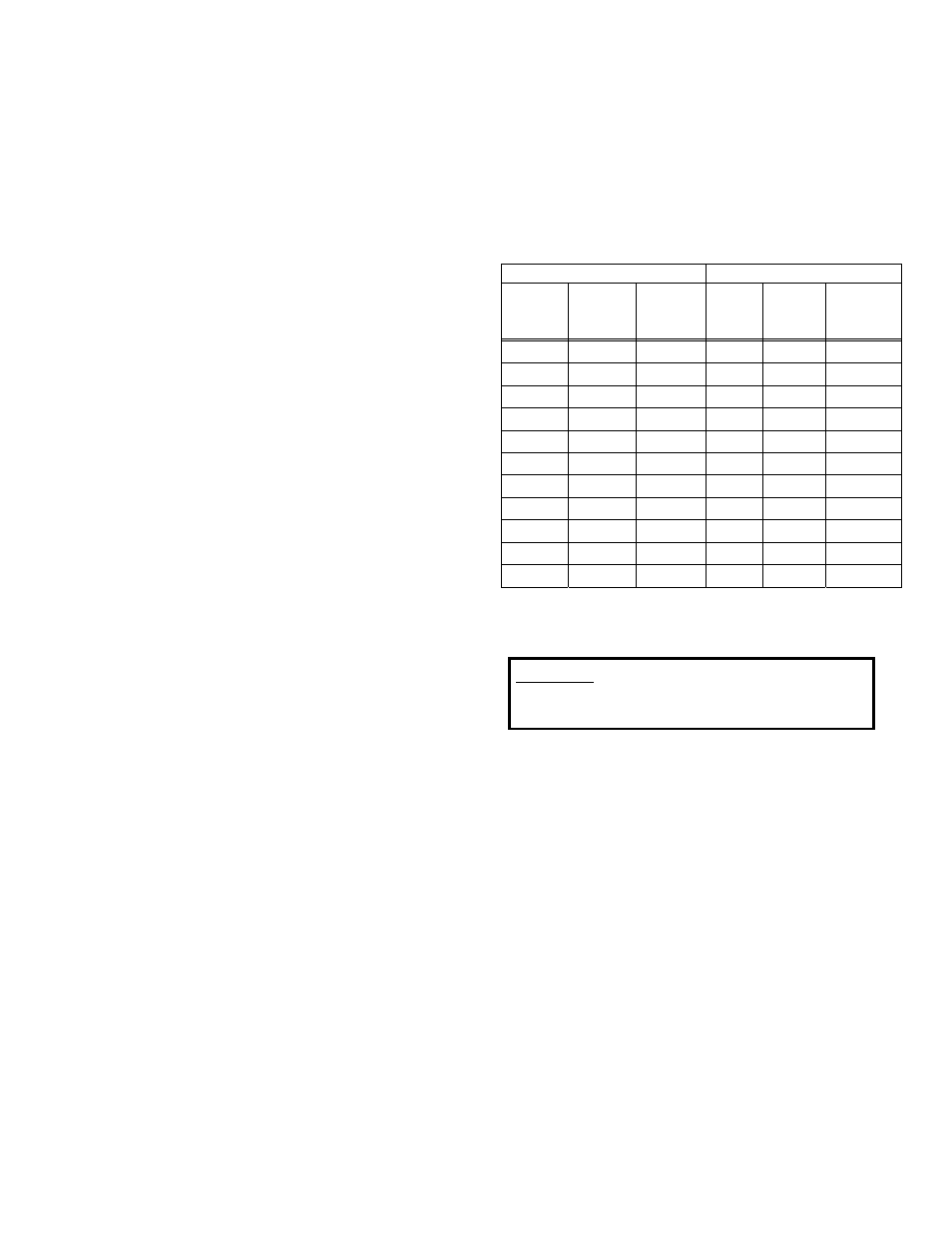

125# FLANGE DATA

250# FLANGE DATA

Valve

Size

(in)

Bolt

Dia.

(in)

Bolt

Torque

(ft-lbs)

Valve

Size

(in)

Bolt

Dia.

(in)

Bolt

Torque

(ft-lbs)

14 1

80-250

14 1

1/8

140-450

16 1

90-300

16 1

1/4

180-600

18 1

1/8

100-350

18 1

1/4

190-600

20 1

1/8

120-450

20 1

1/4

220-600

24 1

1/4

150-500

24 1

1/2

350-900

30 1

1/4

180-600

30 1

3/4

500-1200

36 1

1/2

250-700

36 2

700-1500

42 1

1/2

300-800

42 2

800-1600

48 1

1/2

400-900

48 2

900-1800

54 1

3/4

500-1200

60 1

3/4

700-1500

TABLE 1. FLANGE BOLT TORQUES

CAUTION:

The use of excessive bolt torque

may damage valve.