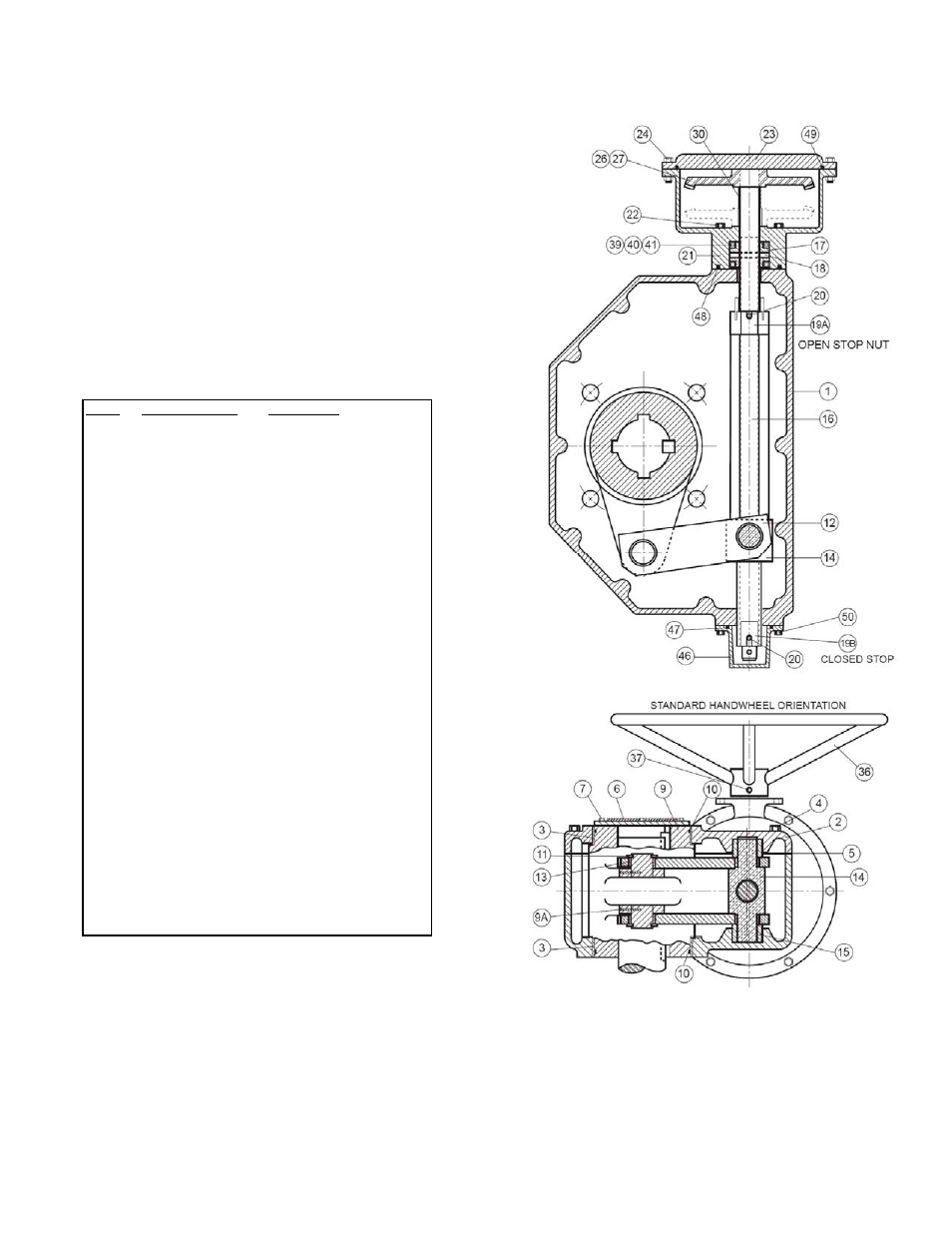

Val-Matic 30 and Larger Butterfly Valve With LSA Actuator and External Stops User Manual

Page 9

8

ITEM DESCRIPTION MATERIAL

1

Housing

Cast Iron

2

Cover

Cast Iron

3

Bushings

Teflon / Fiberglass

4

Cover Bolts

Stainless Steel

5

Gasket

RTV Sealant

6

Indicator

Cast Iron

7

Indicator Bolts

Stainless Steel

8

Gasket

RTV Selant

9

Lever

Ductile Iron

9A

Locking Pin

Alloy Steel

10

O-Ring

Buna-N

11

Retaining Ring

Steel

12

Link

Steel

13

Link Bushing

Teflon / Fiberglass

14

Crosshead

Bronze

15

Guides

Bronze

16

Shaft

Steel

17

Thrust Collar

Bronze

18

Thrust Collar Pin Steel

19

Stop Nuts

Steel

20

Stop Nut Pins

Steel

21

Bevel Gear

Cast Iron

22

End Cap Bolts

Alloy Steel

33

Stem O-ring

Buna-N

36

Handwheel

Steel or Cast Iron

37

Pin

Steel

39

Ball Bearings

Steel

40

Bearing Race

Steel

46

Stop Cover

Cast Iron

47

Cover O-Ring

Buna-N

48

End Cap O-ring Buna-N

50

Stop Cover Bolts Stainless Steel

turn, drives a slotted lever (4) through 90 degrees of

travel. The lever (4) drives the valve shaft with a

square key. The rotation of the shaft is displayed by

the top indicator (19). The full open and closed

positions are controlled by the stop nuts (6). The

stop nuts can be adjusted by pounding out the pin (7)

with a drift punch and rotating the stop nut ½ turn. The

gear box is factory lubricated and sealed. No regular

maintenance is required. If difficult operation is

observed, the cover can be removed and the unit

inspected for wear. All moving parts should be coated

with grease. The grease should have an even and

smooth consistency. If needed, coat all moving parts

with an EP-2 grease such as Mobil Mobilux EP2.

Buried units should be packed 90% with grease.

TABLE 6. TRAVELING NUT ACTUATOR PARTS

FIGURE 9. TRAVELING NUT ACTUATOR

CONSTRUCTION