Val-Matic 30 and Larger Butterfly Valve With LSA Actuator and External Stops User Manual

Page 8

7

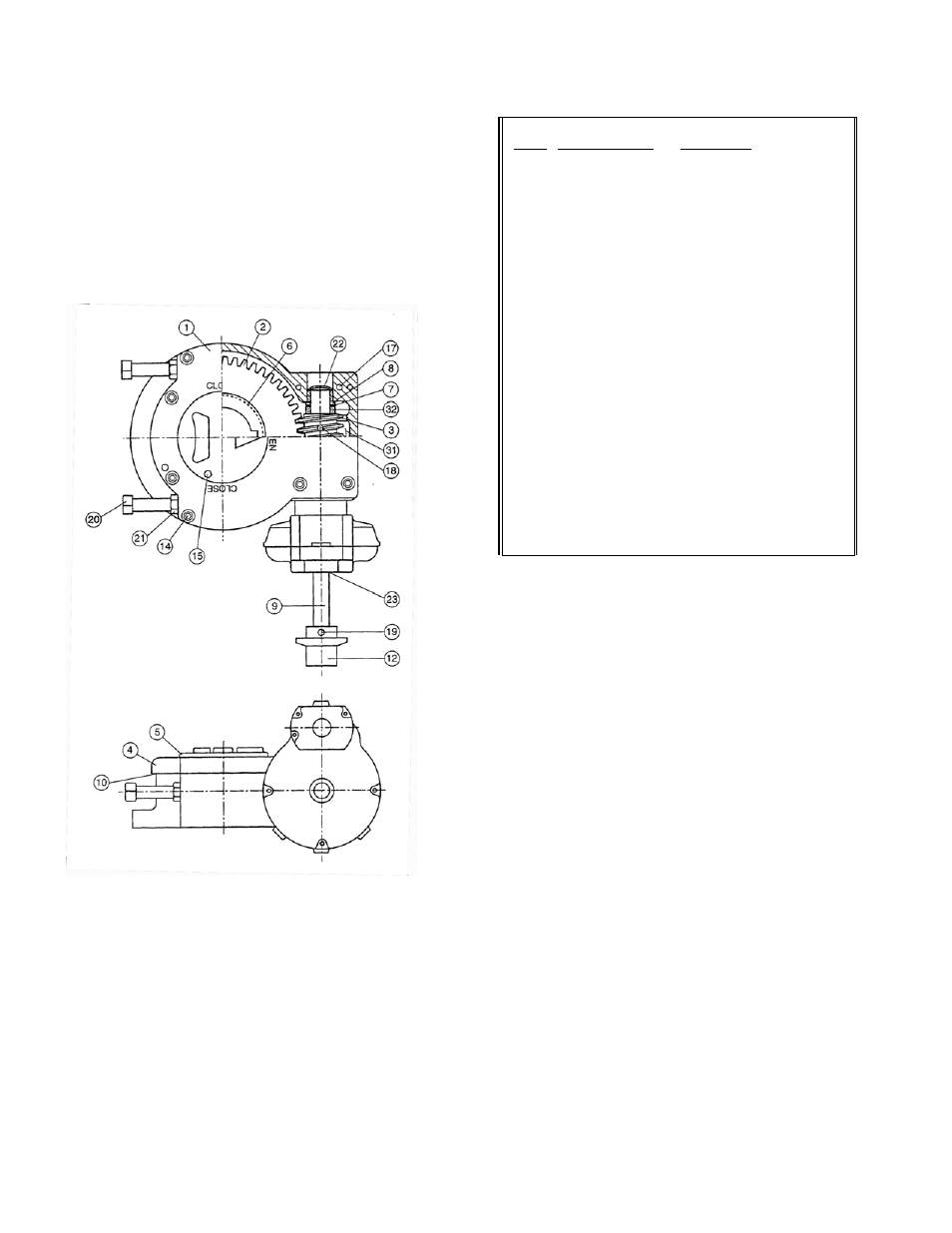

ITEM DESCRIPTION MATERIAL

1

Housing

Cast Iron

2

Segment Gear

Bronze or DI

3

Worm

Alloy Steel

4

Cover

Cast Iron

5

Indicator

Cast Iron

6

O-Ring

Buna-N

7

Thrust Bearing

Carbon Steel

8

Bearing

Bronze

9

Shaft

Carbon Steel

10

Gasket

Non-Asbestos

12

Operating Nut

Cast Iron

14

Cover Bolt

Carbon Steel

15

Indicator Bolt

Steel

17

Locating Pin

Steel

18

Worm Pin

Steel

19

Spring Pin

Steel

20

Stop Screw

Steel

21

Jam Nut

Steel

22

Plug

Steel

23

Oil Seal

Steel & Rubber

30

Spur Gear

Cast Iron

31

Grease

EP-2

32

Worm Spacer

Steel

8. Reinstall actuator mounting plates. Clean off all

grease from the surfaces of the actuator mounting

surfaces.

9. With valve in the closed position, place actuator

over valve and reinsert key (14).

10. Finally, with valve closed, install cover on actuator

indicating “Closed".

FIGURE 8. GEAR ACTUATOR CONSTRUCTION

TABLE 5. WORM GEAR PARTS LIST

WORM GEAR ACTUATOR MAINTENANCE: A typical

worm gear actuator is shown in Figure 8 and consists

of a worm (3) mounted on an input shaft (9). The

worm engages a segment gear (2). When the worm is

turned, it drives the segment gear through 90

of

rotation. The rotation of the segment gear is displayed

by the top indicator (5). The gears are lubricated with

EP2 grease in a cast iron housing (1). The open and

closed positions of the segment gear (2) are controlled

by the end position stop bolts (20). The stops can be

adjusted by loosening the lock nut (21) and rotating the

bolts (20).

The gearbox is factory lubricated and sealed. No

regular maintenance is required. If difficult operation is

observed, the cover can be removed and the unit

inspected for wear. All moving parts should be coated

with grease. The grease should have an even and

smooth consistency. If needed, coat all moving parts

with an EP-2 grease such as Mobil Mobilux EP2.

Buried units should be packed 90% with grease.

TRAVELING NUT ACTUATOR MAINTENANCE: A

typical traveling nut actuator is shown in Figure 9 and

consists of a threaded nut (12) which travels back and

forth on a threaded stem (14). The stem is lubricated

with EP2 grease in a cast iron housing (1). The nut, in