Installation – Val-Matic 2-12 in. (DN 50-300 mm) Wafer Style Dual Disc Check Valve User Manual

Page 3

INSTALLATION

The installation of the valve is important for its

proper operation. The flow arrow on the valve body

must point in the direction of flow when the system is

in operation. The valve can be installed in horizontal

lines with the disc hinge pin in the vertical position,

or in vertical lines with the flow up. Valves for air

service (Series 8900) require special springs to allow

full valve opening.

CAUTION: When installed in horizontal lines,

the check valve must be installed

with the disc hinge pin in the

vertical position

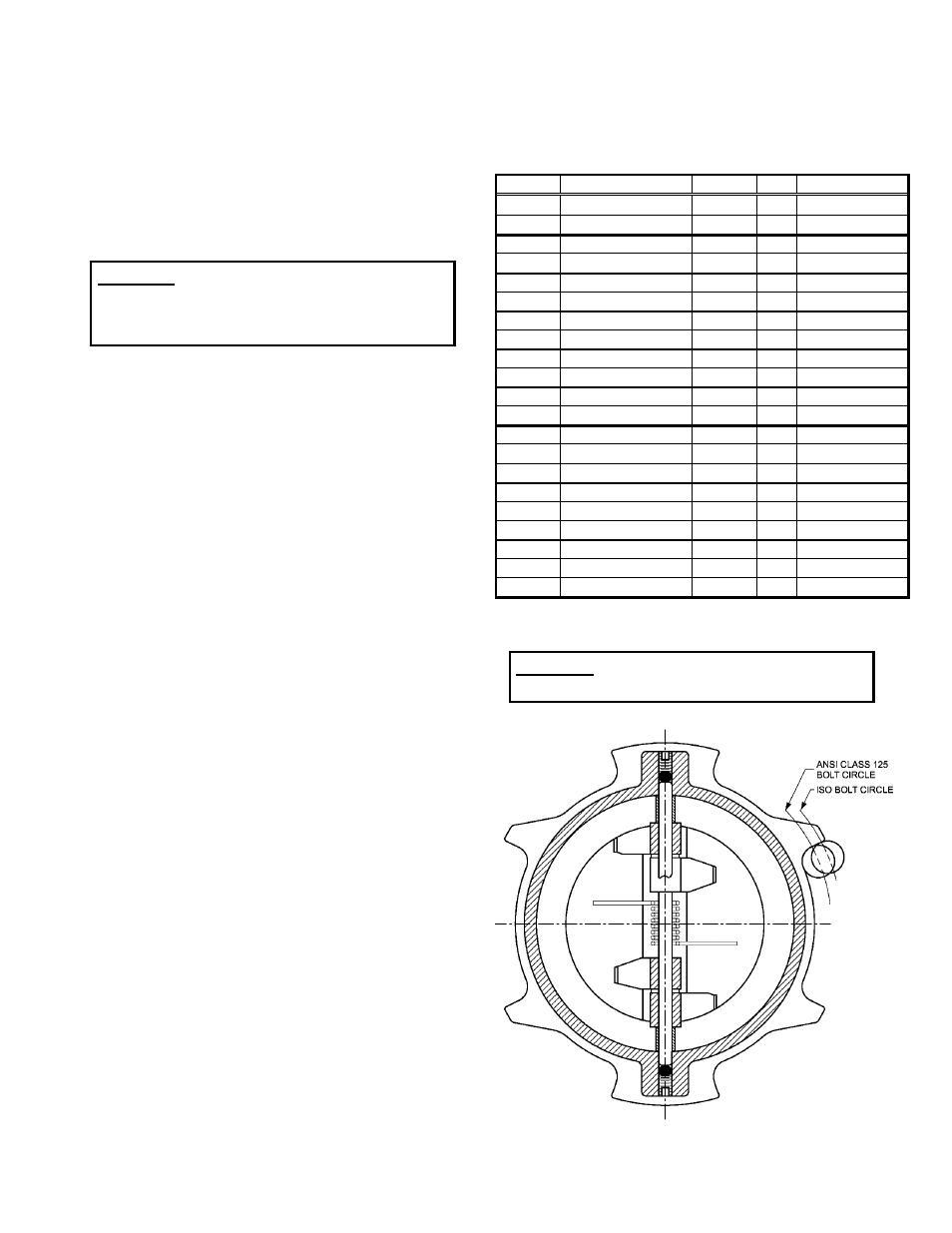

The valve should be installed between standard

flanges that correspond to the dimensions given in

ANSI B16.1 for 125# flanges or to those given in

ISO 7005 for PN10 and PN16 flanges (See Table 1).

Special integrally-cast locating tabs are provided

around the exterior to enable the valves to fit

between these different bolt patterns. (See Figure 2)

The number of tabs varies by valve size. (Note: for

some sizes tabs are not provided because the

desired universal fit is accomplished without them)

The gasket can be rubber or compressed fiber.

Ring gaskets are appropriate for this wafer style

check valve, but full-face flange gaskets may be

substituted. The studs or bolts used should span

the full length of the valve.

Three diameters of straight pipe upstream of the

valve are recommended to prevent turbulent flow

streams through the valve, which can cause

vibration and wear.

When mating the check valve with butterfly isolation

valves, the isolation valve must be installed at least

one diameter downstream of the check valve,

because, in most sizes, the check valve discs

extend beyond the downstream flange face and may

interfere with the operation of adjacent valves. In

these sizes, a short run of pipe or spacer is needed

between the check valve and the isolation valve.

INSTALLATION PROCEDURE: Lower valve

between mating flanges. NPS 10-12 (DN 250-300)

valves are provided with a lifting eyebolt to aid in this

process. Lubricate the flange bolts or studs and

insert them around the flange. Lightly turn bolts or

nuts until gaps are eliminated. The tightening of the

nuts should then be done in graduated steps using

the cross-over tightening method. Recommended

lubricated torques for use with resilient gaskets are

given in Table 1.

If leakage occurs, allow gaskets to absorb fluid and

check torque and leakage after 24 hours. Do not

exceed bolt rating or crush gasket more than 50 per

cent of its thickness.

Size

Class

Bolt size Qty

Bolt Torque

NPS 2

ANSI 125#

5/8 in.

4

25-75 ft-lb

DN 50

ISO 7005 PN16

M16

4

40-120 N-m

NPS 2.5

ANSI B16.1 125#

5/8 in.

4

25-75 ft-lb

DN 65

ISO 7005 PN16

M16

4

40-120 N-m

NPS 3

ANSI B16.1 125#

5/8 in.

4

25-75 ft-lb

DN 80

ISO 7005 PN16

M16

8

40-120 N-m

NPS 4

ANSI B16.1 125#

5/8 in.

8

25-75 ft-lb

DN 100

ISO 7005 PN16

M16

8

40-120 N-m

NPS 5

ANSI B16.1 125#

3/4 in.

8

40-120 ft-lb

DN 125

ISO 7005 PN16

M16

8

40-120 N-m

NPS 6

ANSI B16.1 125#

3/4 in.

8

40-120 ft-lb

DN 150

ISO 7005 PN16

M20

8

65-200 N-m

NPS 8

ANSI B16.1 125#

3/4 in.

8

50-150 ft-lb

DN 200

ISO 7005 PN10

M20

8

65-200 N-m

DN 200

ISO 7005 PN16

M20

12

65-200 N-m

NPS 10

ANSI B16.1 125#

7/8 in.

12

60-180 ft-lb

DN 250

ISO 7005 PN10

M20

12

65-200 N-m

DN 250

ISO 7005 PN16

M24

12

100-300 N-m

NPS 12

ANSI B16.1 125#

7/8 in.

12

65-200 ft-lb

DN 300

ISO 7005 PN10

M20

12

80-240 N-m

DN 300

ISO 7005 PN16

M24

12

125-375 N-m

TABLE 1. FLANGE BOLT TORQUES

CAUTION:

The use of excessive bolt torque

may damage valve.

FIGURE 2. INTEGRALLY-CAST LOCATING TABS

2