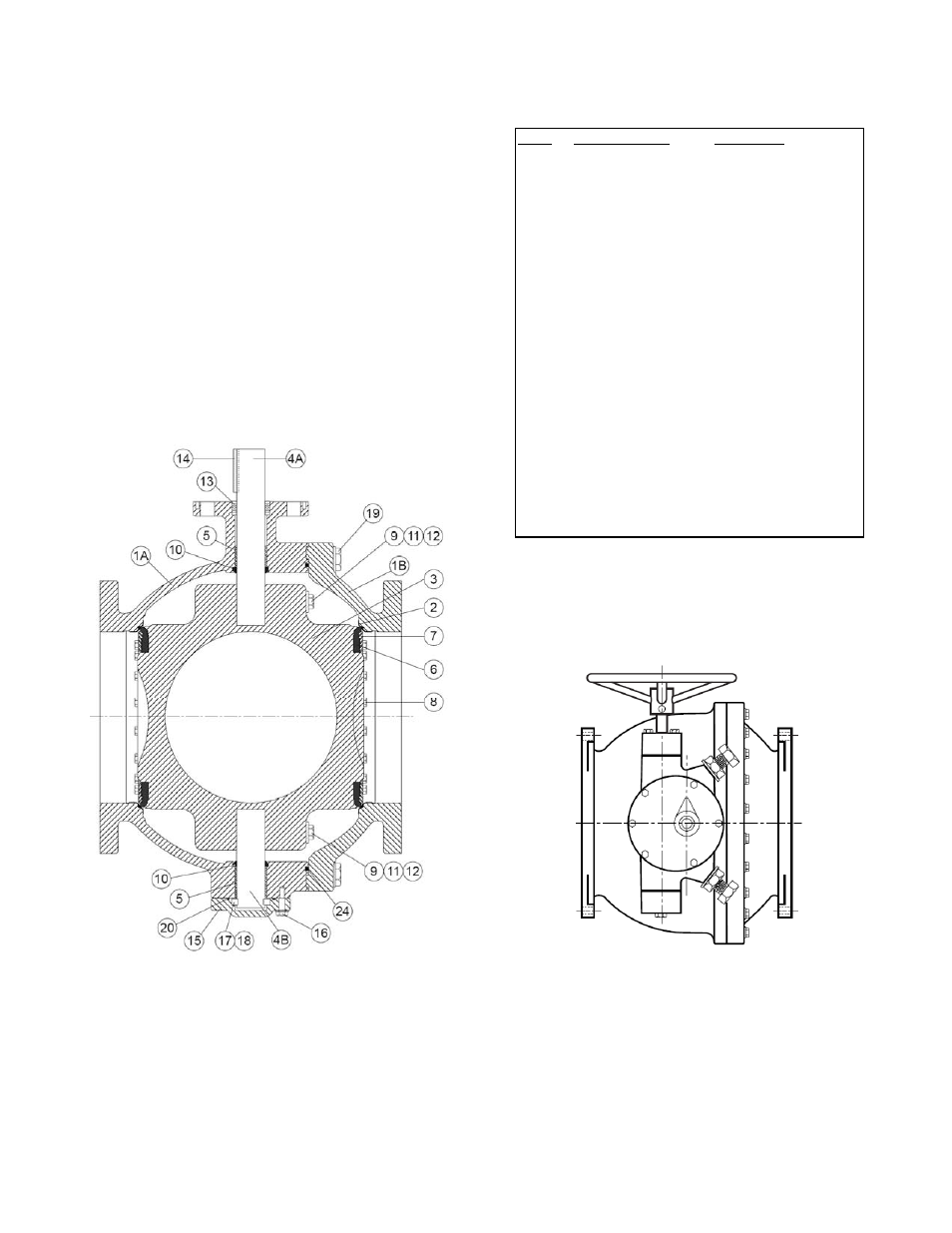

Valve construction – Val-Matic Rubber-Seated Ball Valve User Manual

Page 3

3

ITEM DESCRIPTION MATERIAL

1

Body

Gray or Ductile Iron

2

Body Seat

Stainless Steel

3

Ball

Gray or Ductile Iron

4

Shaft

Stainless Steel

5

Sleeve Bearing*

Teflon/Fiberglass

6

Resilient Seat*

Resilient

7

Seat Retaining Ring Stainless Steel

8

Ret. Ring Screws* Stainless Steel

9

Taper Pin

Stainless Steel

10

Grit Seal *

Molythane

11

Taper Pin Bolt

Stainless Steel

12

Taper Pin Washer Stainless Steel

13

Packing*

Buna-N

14

Key

Carbon Steel

15

Thrust Bearing Cap Ductile Iron

16

Cap Screws

Carbon Steel, Plated

17

Thrust Brg. Shims

Brass

18

Thrust Bearing

Bronze

19

Body Bolts

Carbon Steel, Plated

20

Cap O-ring

Resilient

24

Body O-ring

Resilient

*Recommended Spare Part

VALVE CONSTRUCTION

The standard Series 4000 Ball Valve is constructed of

rugged cast iron with stainless steel shafts and resilient

seat. See the specific Materials List submitted for the

order if other than standard cast iron construction. The

details of construction are illustrated in Figure 2.

The body (1) is available with Class 150# or Class

300# flanged ends for connection to the pipeline. The

body is equipped with a stainless steel seat (2). The

1/4 turn ball (3) is guided by a stainless steel shaft (4)

which rotates in non-metallic bearings (5) fixed in the

body. Leak-tight closure is made when the resilient

seat (6) located on the ball. If the valve is labeled as a

“Single” seat valve, the seat will be on the right end

and this is the end that is installed toward the pump.

FIGURE 2. BALL VALVE PARTS LIST

TABLE 1. STANDARD VALVE PARTS LIST

FIGURE 3. VALVE WITH MANUAL ACTUATOR