Val-Matic Rubber-Seated Ball Valve User Manual

Page 11

11

REASSEMBLY

All parts must be cleaned and gasket surfaces should

be cleaned with a stiff wire brush in the direction of the

serrations or machine marks. Worn parts, gaskets and

seals should be replaced during reassembly. Valve

and actuator mounting bolts should be lubricated and

torqued per Table 7 during reassembly.

TABLE 7. LUBRICATED BOLT TORQUES

1. Place the long body half (1A) on the floor or

bench. Insert the grit seals (10) in the bores.

2. Apply a bead of loctite 680 on new sleeve

bearings (5) and insert into both ends of the valve

body (1A) until flush with grit seal. Insert the

shafts (4) through the body and grit seals (10).

3. Lower the ball (3) into place with a nylon strap and

lower the taper pins (9) into their bores so that the

flat portion is toward the shaft.

4. Push the shafts until their flat portions are aligned

with the taper pin flats. Lift the taper pins with

threaded rod. Apply food-grade anti-seize

compound to the threads and secure with the

taper pin bolts (11) and washers (12).

5. Install new seat (6), retaining ring (7) and seat

bolts (8) into ball. Apply thin film of food-grade

grease such as Dow Corning #7 to rubber surface.

Lightly tighten seat bolts until bolt heads touch

body ring.

6. Install thrust bearing cap (15), thrust bearing (18)

and, thrust shims (17) with the o-ring seal (20).

7. Lubricate ID and OD of packing set with food-

grade grease and install in packing bore one ring

at a time taking care to keep lips pointing down

toward valve.

8. Install body o-ring (24) and short body half (1B)

with body bolts (19).

9. With valve fully closed, torque seat bolts in a

cross-over pattern to torque given in Table 4.

10. Insert key (24) into shaft and place actuator over

valve. Reinstall actuator mounting bolts and

torque per Table 7. Install cover on actuator.

Cycle valve. Apply pressure to valve and check

for seat leakage. Tighten seat bolts ½ turn at a

time as necessary.

11. If valve does not shut off tight, adjust the closed

position stops as described on page 6 under

"Closed Position Adjustment". so that ball face is

parallel to body flange within 1/8 in.

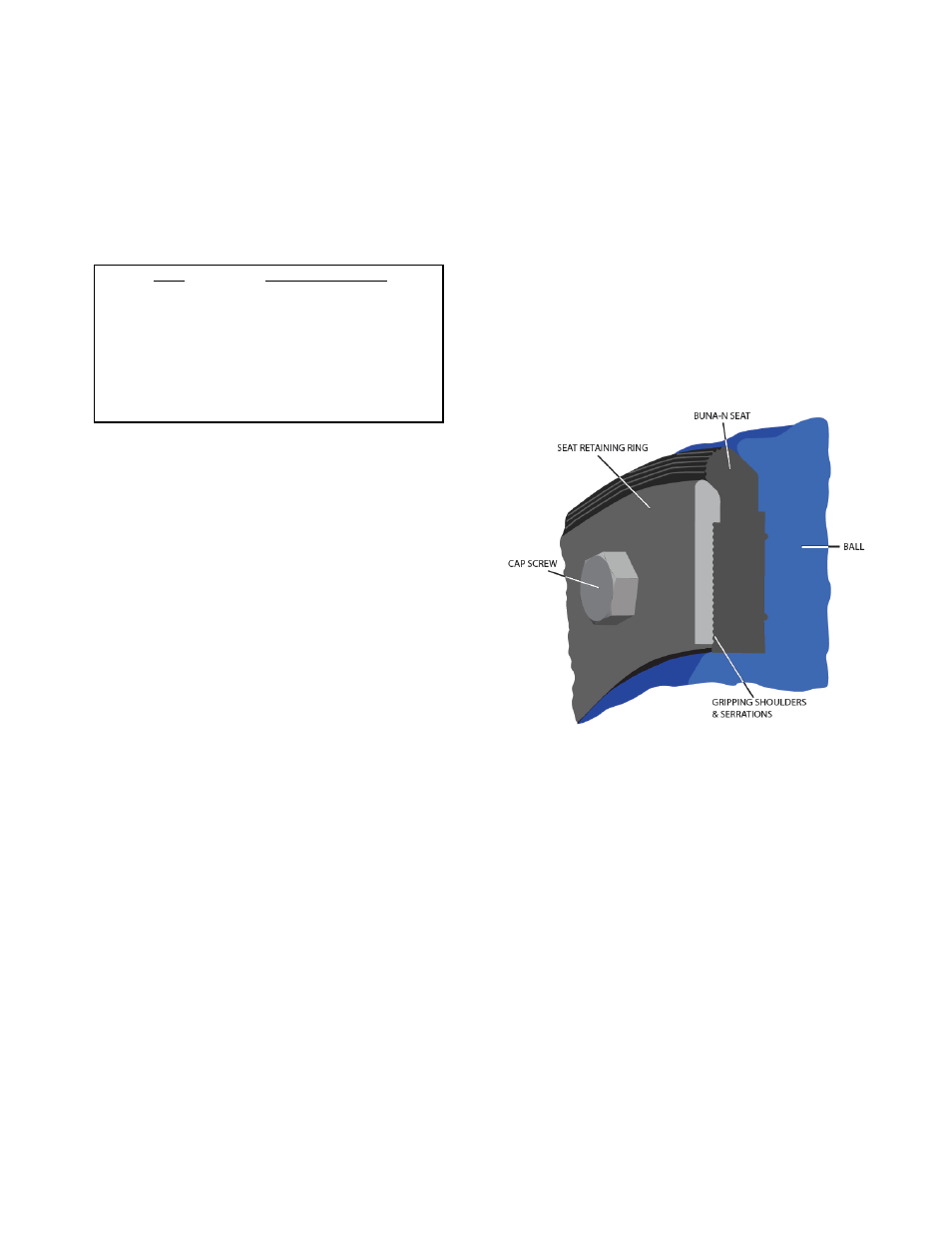

FIGURE 9. RUBBER SEAT

SEAT REPLACEMENT

If the seat is badly worn or damaged, gain access to

valve interior and remove existing cap screws, seat

retaining ring, and seat.

1. Clean mating surfaces of body seat, ball and

retaining ring with stiff wire brush in the direction of

the machine grooves.

2. Install new seat (6) onto ball so that the o-ring

bead side is against the disc with the holes

aligned.

3. Start at the top of the ball and install a section of

retaining ring (7) with three new seat bolts (8) and

lightly tighten seat bolts until the bolt heads touch

the retaining ring.

SIZE

TORQUE

(FT-LBS)

1/2"-13

45 - 75

5/8"-11

100 - 150

3/4"-10

150 - 250

7/8"-9

200 - 350

1"-8

300 - 500

1 1/8"-7

450 - 700

1 1/4"-7

650 - 1000