Val-Matic 1/2-3 Well Service Air Valve With Dual Port Throttling Device User Manual

Page 3

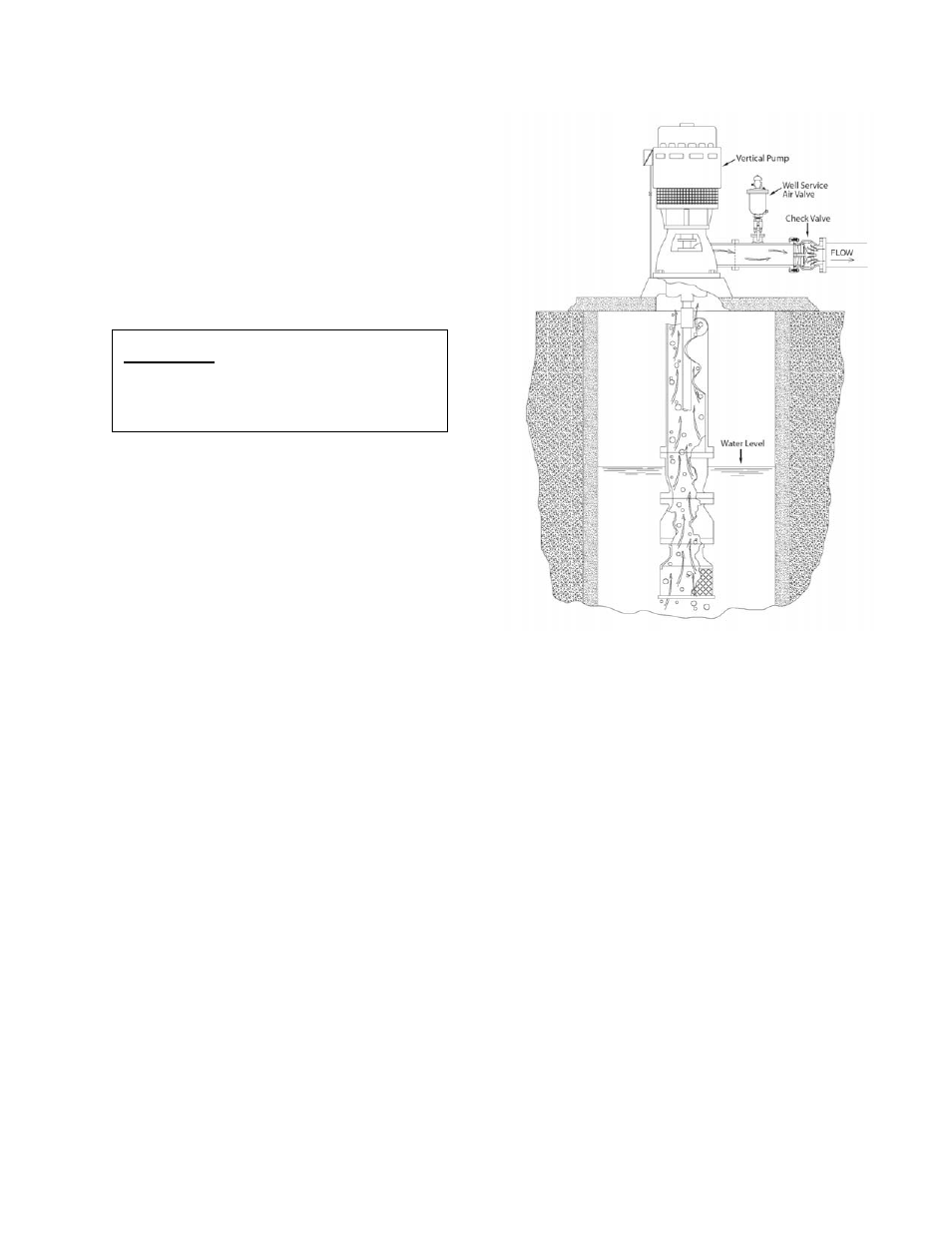

INSTALLATION

The installation of the valve is important for its

proper operation. The valves must be installed

in the vertical position with the inlet down on the

discharge pipe between the pump and check

valve, see Figure 2. During closure, some fluid

discharge will occur so vent lines should extend

to a safe location or open drain for in-plant

installations. A shutoff valve should be installed

below the valve in the event servicing is

required.

THROTTLING DEVICE: The throttling device

should be screwed into the outlet of the air

valve. The outlet connection of the device

should be piped to a safe location or open drain.

Install the device with the adjustable screw in

the mid position.

If there is a sudden pressure spike in the pump

discharge line during pump startup, then throttle

the device closed until the pressure surge is

reduced. NOTE: Even when fully throttled,

there is still 5% flow area through the throttling

device.

If air is driven through the main check valve

during pump startup, then open the throttling

device further to allows a faster rate of air

discharge. A lock nut is provided to lock the

final setting.

CAUTION:

Remove packing from

outlet and install valve

with “INLET” port down or

leakage will occur.

Figure 2. Pump Installation

2