Val-matic’s 1/2”-3” well service air valve, Operation, maintenance and installation, Introduction – Val-Matic 1/2-3 Well Service Air Valve With Dual Port Throttling Device User Manual

Page 2: Receiving and storage

VAL-MATIC’S 1/2”-3” WELL SERVICE AIR VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information

to properly install and maintain the valve to

ensure a long service life. The Well Service Air

Valve has been designed with stainless steel

trim to give years of trouble free operation. The

purpose of the valve is to automatically

discharge and admit air into the discharge pipe

of a vertical turbine or well pump.

The Size, Maximum Working Pressure, and

Model No. are stamped on the nameplate for

reference.

NOTE:

While Well Service Air Valves will

exhaust large quantities of air upon start-up,

they will not continuously release air during

system operation. For that function, a

Combination or Air Release Valve is required in

the piping system.

Also, this valve is not intended for fluids

containing suspended solids such as

wastewater. For wastewater and other high

turbidity applications, use Val-Matic Series 300

Wastewater Air/Vacuum Valves.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in

shipment. Unload all valves carefully to the

ground without dropping.

Valves should remain boxed, clean and dry until

installed to prevent weather related damage. Do

not expose seat to sunlight or ozone for any

extended period.

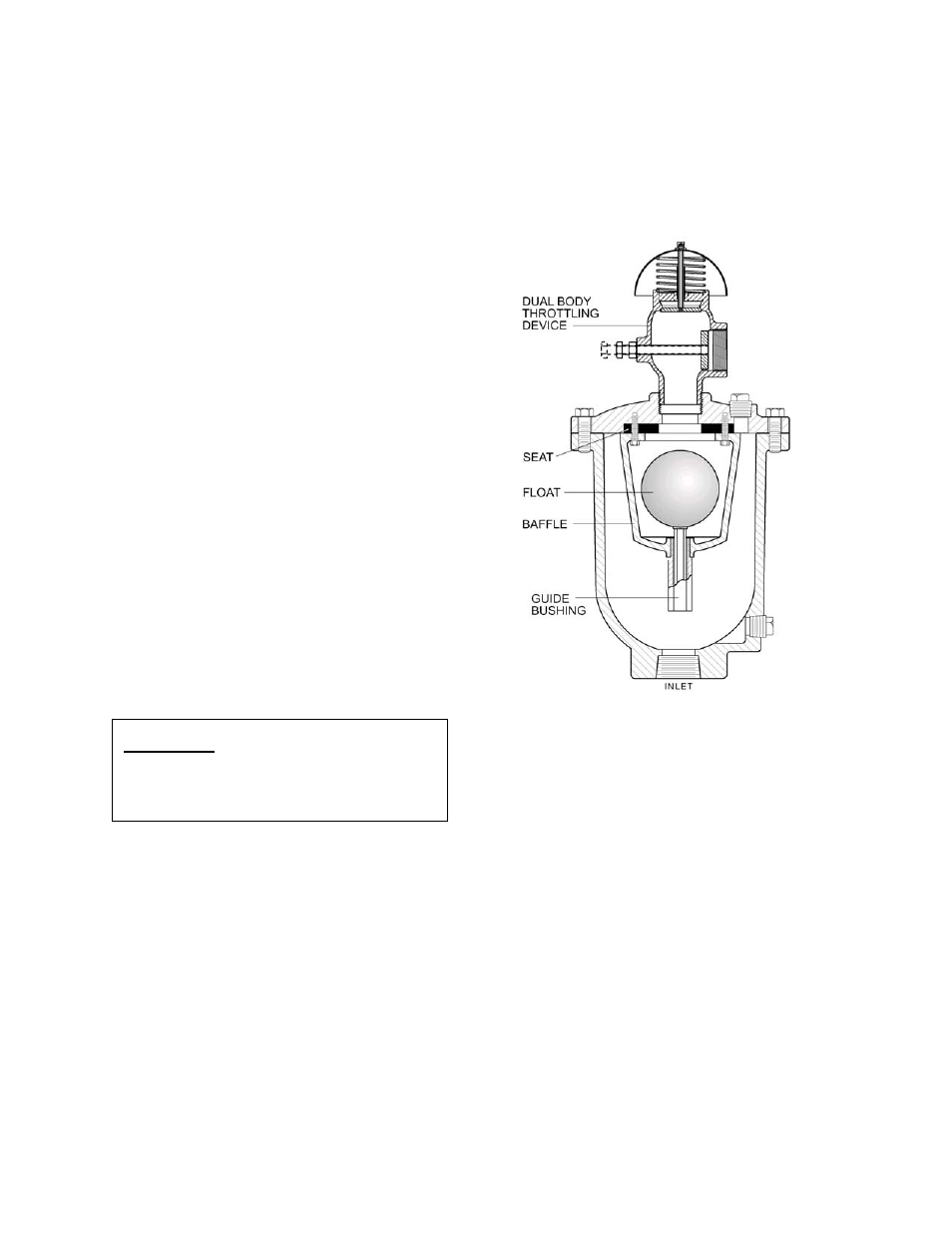

Figure 1. 1/2”-3” Well Service Air Valve

CAUTION:

This valve is not intended

for fluids containing

suspended solids or

hazardous gases.

DESCRIPTION OF OPERATION

The valve is designed to exhaust large

quantities of air upon pump start-up and allow

air to reenter the line upon pump shutdown. As

water enters the valve during startup, the float

will rise and close the outlet port. The exhaust

rate is controlled by the throttling device and

helps reduce surges in the pump column. The

valve will remain closed while the pump is

running.

The only moving parts in the valve are the float

and the float guide. The float guide assures that

the float makes contact with the resilient seat at

the optimum angle.

The external bolt in the throttling device allows

field-adjustable control of the air exhaust rate.

1