Troubleshooting, Continued) – Rapid-Air MULTI-STROKE CONTROL User Manual

Page 7

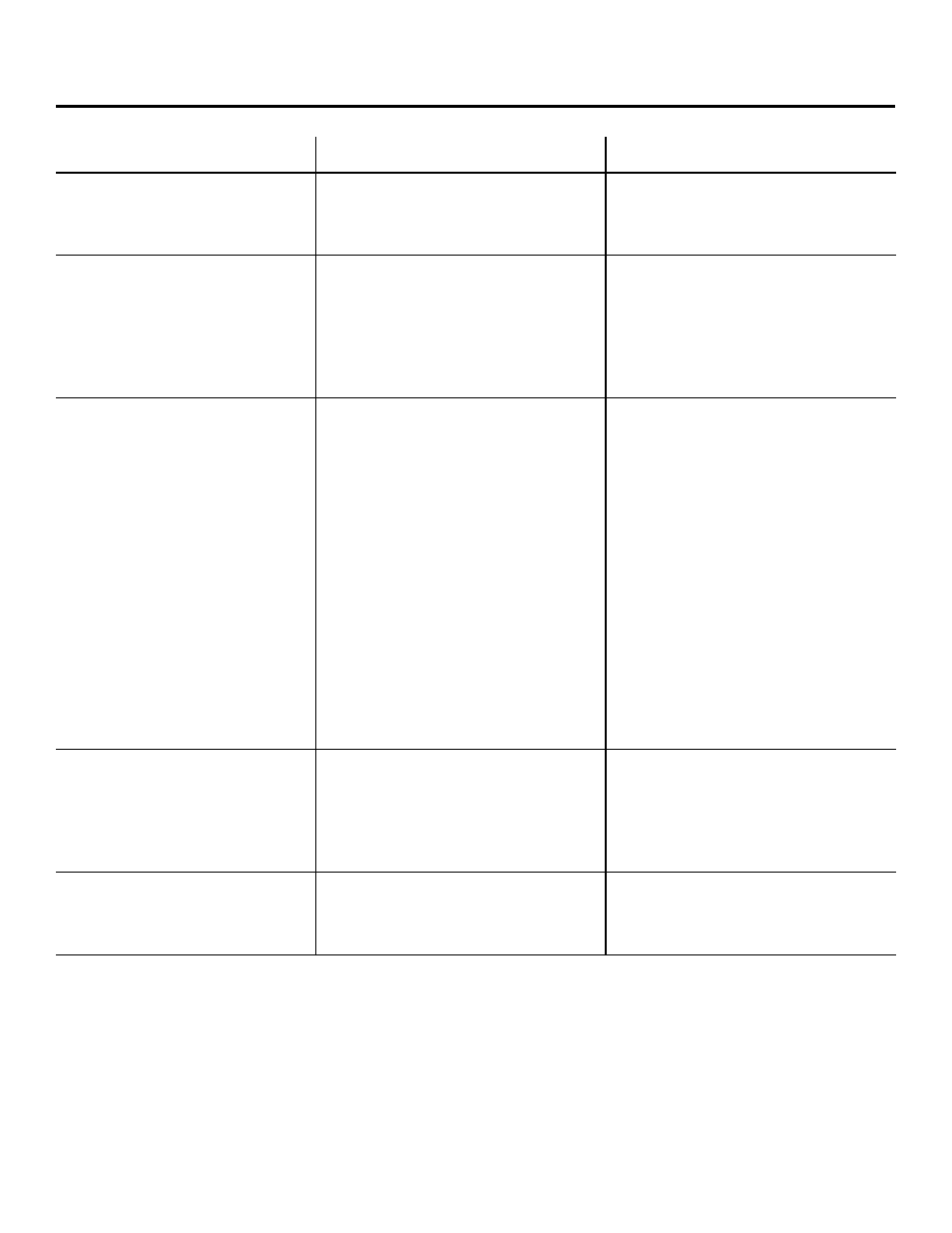

feed has difficulty pushing last

part of progression.

Over feeding.

under feeding.

Slide block will move out okay, but

will not return without hesitation.

feed acts sluggish on start up.

Okay after running for a while.

troubleshootinG

(continued)

Problem. .................................Probable.Causes. ..............................................Remedy

– feed is not inline with die.

– Stock excessively dirty or oily.

– feed is operating too fast.

– Stock and feed clamps may be loose.

– Insufficient air pressure.

– Stock has large slitting burr.

– Stock clamp and feed clamps

are loose.

– feed is not lubricated.

– Stock excessively dirty.

– feed may be feeding before

punches are clear from stock or die.

– feed may be operating too slow.

– Check speed adjusting screw.

– Check pilot operated valve.

Swollen “O” ring could be binding,

until pressure build up breaks it free.

Check poppet valve.

– Check pilot operated valve for

“O” rings binding. Valve should

move freely in cartridge

– A slight angular adjustment of the

feed will reduce the binding of the

stock on the die guides.

– Clean unit and stock. Run and retest.

– Turn speed adjusting screw clockwise

to slow down.

– Although nuts are self locking, they

can in time work themselves loose;

retighten the nuts.

– Adjust air pressure between 80

and 100 PSI.

– Check clearance between clamps

and stock.

– Although nuts are self locking they

can in time work themselves loose;

retighten them.

– Check lubricator in air inlet, there

should be oil in the bowl.

– Clean away dirt which may be

present between slide block and

main body area.

– Adjust the amount of depression of

the actuating valve.

– Turn speed adjusting screw counter-

clockwise to increase speed.

– Adjust for smooth operation.

– Check moisture content in air lines.

Change “O” rings.

– This usually occurs after a period

of non-running. After running unit for

a while the unit usually frees up okay.