B0ard components and troubleshooting, Air feed progression set-up – Rapid-Air MULTI-STROKE CONTROL User Manual

Page 4

There.are.two.switches.on.the.

board.for.changing.the.operation.

of.the.cut-to-length.

1. The first switch is a bat or toggle

switch. It is located just above

the transformer on the board.

when the switch position is to the

left of the board, then the air feed

will run at a normal speed.

when the switch position is to

the right of the board or facing

the board connector, then the

speed of the cycle with the feed

rate potentiometer set at “low”

would be equal to the normal

setting with the feed rate

potentiometer set at “high”.

A. Set bat switch left and turn

feed rate potentiometer to

high. Record cycles per

minute.

B. Set bat switch right and

turn feed rate

potentiometer to low. Cycles

per minute should be

about the same as in “A”.

Turn feed rate to high and

record cycles per minute.

2. The second switch is a slide

switch. It is located in the upper

middle of the board. when the

switch is set to the lower

position, the control can be

started by turning the selector

switch from stop to start and then

releasing it, or by an input from

the feed switch to start the cycle.

If the slide switch is set to the

upper position, the control can

only be started by a machine

movement and that is not possible

on an economy cut-to-length unit.

There.are.5.lights.on.the.board.for.

trouble.shooting.purposes.

1. light (l1) is the cycling light,

whenever it is on, the air feed

solenoid should be energized.

2. light (l2) is the selector switch

in run mode light. whenever the

selector switch is in the run

b0Ard comPonents And troubleshootinG

position this light will be on.

3. light (l3) is the selector switch

in start mode light. whenever

the selector switch is in the

start position this light will

be off.

4. light (l4) is the reset signal

device input. If the unit is in run

mode and the reset signal is

activated, the light will be out

for as long as the reset signal

is present.

5. light (l5) is the preset count

complete. whenever the preset

count, set with strokes.per.cycle

selector switch has been

reached, the light will be on and

stay on until the reset signal has

been activated.

There.are.2.fuses.on.the.board

1. fuse (f1) is the fuse for the air

feed solenoid and is a 5 amp

Pico fuse.

2. fuse (f2) is the main board fuse

and is a 5 amp Pico fuse.

The feed guide rollers are adjustable

by loosening the machine screws and

moving the rollers to the desired posi-

tion. for best results the stock should

be centrally located in the feed.

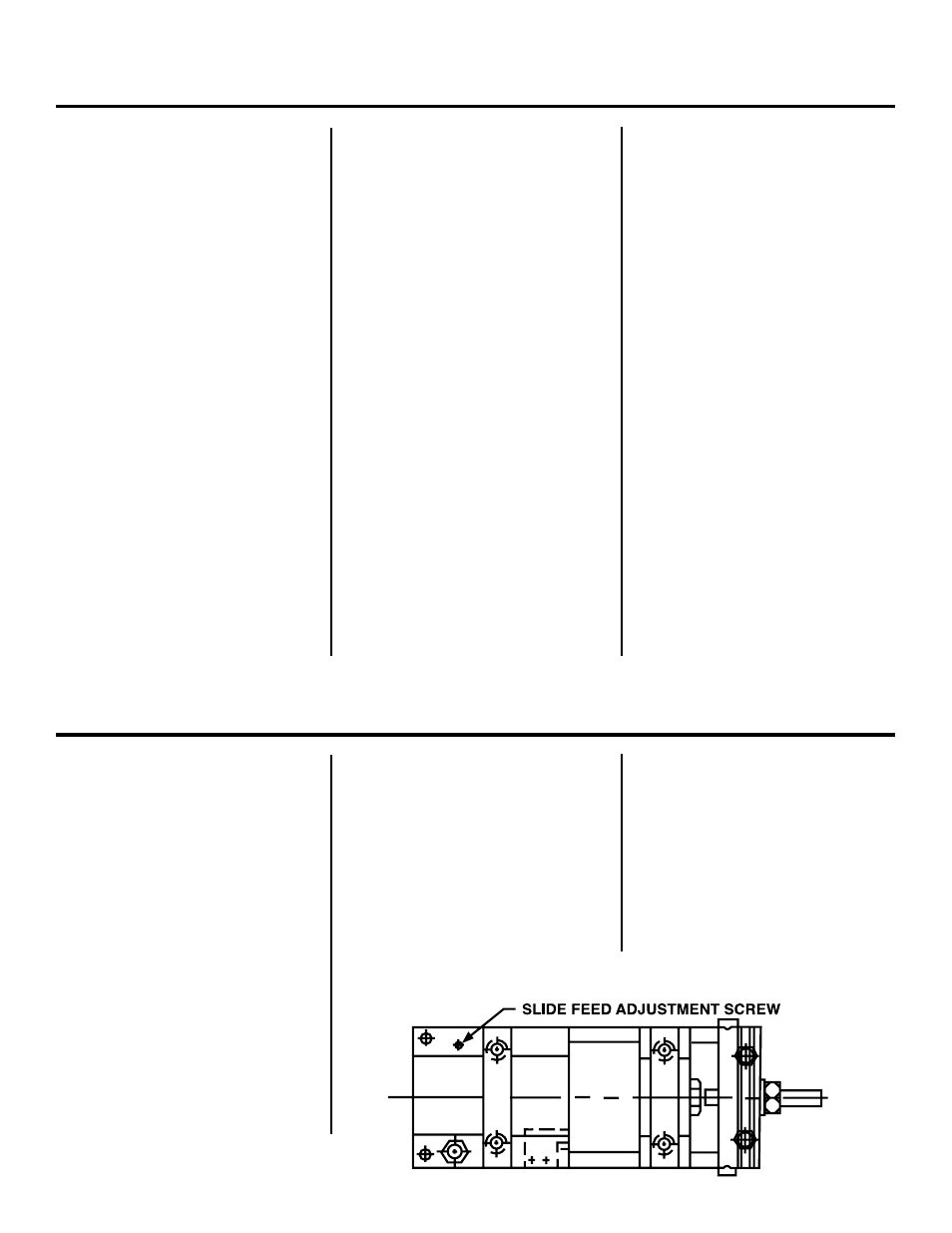

The notches in the guide rails provide

for coarse feed adjustment of the stop

block. The final feed adjustment for

stroke length is made by the screw in

the center of the stop block. The final

feed adjustment is aided by the use

of accurately dimensioned spacers

or gage blocks placed between

the adjusting screw and the main

cushion bolt. The air pressure should

be turned on to keep the slide block

tight against the main body.

with the air pressure turned off, the

material is then inserted between the

guide rollers and passed under the

feed clamp. lift the stock clamp and

push the material through to the start-

ing position. Turn on the air (75-120

PSI) and the feed is ready to operate.

The last adjustment, if necessary,

would be the speed adjusting

valve. The valve adjustment is

located on top of the main body

on the opposite side of the actuating

valve. Adjust the screw for

minimum impact by turning

clockwise. for faster speed

turn counterclockwise.

when the impact is high, slippage

is possible resulting in poor

repeatability as well as part fatigue.

Refer to the diagram below.

Air feed ProGression set-uP