Programming procedure – Rapid-Air SERVO FEED: 104CJ, 108CJ, 106CJ, 112CJ User Manual

Page 5

operator.input.section

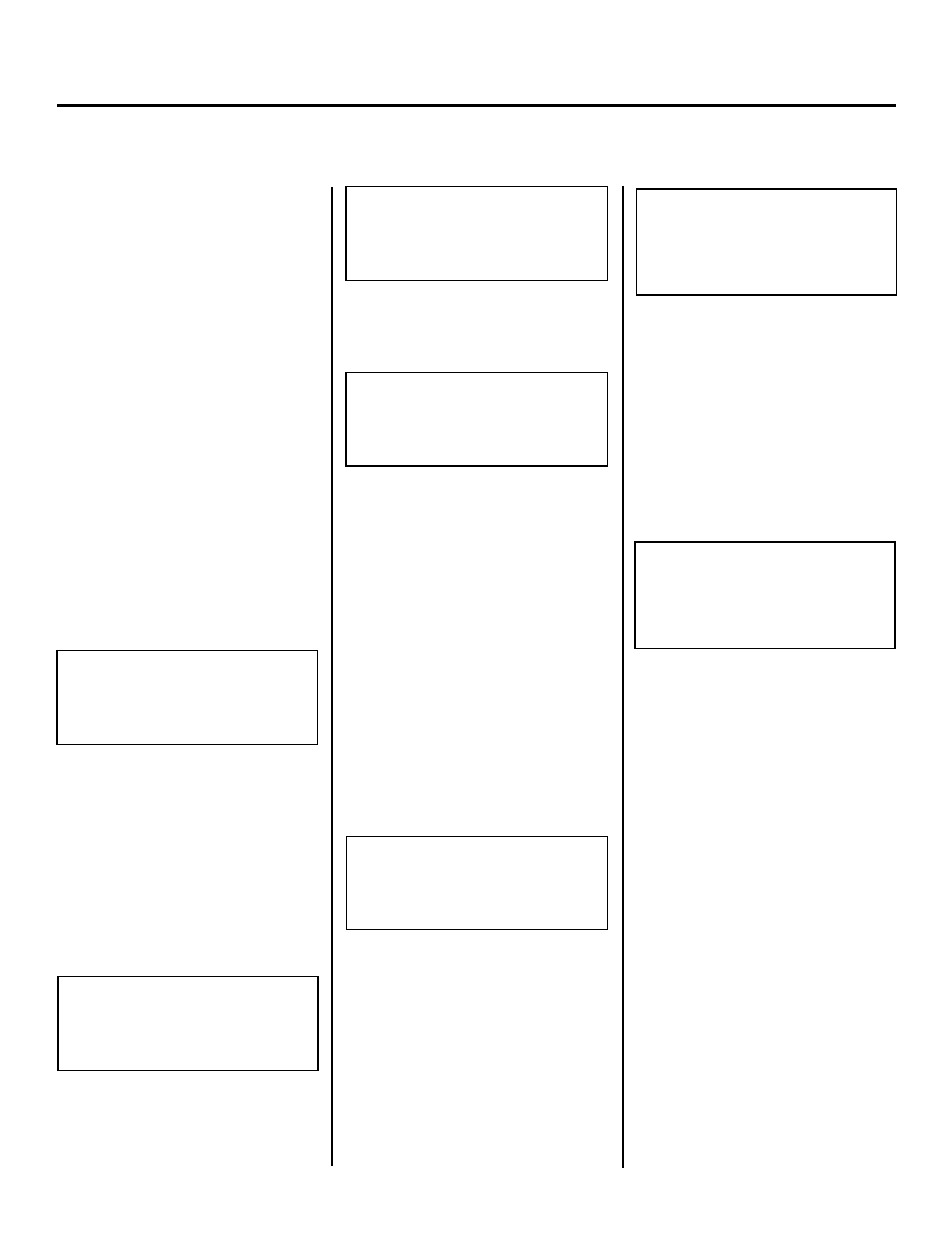

PROGRAmmING PROCEDURE

The intent of this section is to famil-

iarize the operator with the flow of

the program and what to expect with

each key press. each program screen

of the servo will be displayed

and also comments to clarify possible

questions. There are four sections

that will be explained and they are as

follows

section.1.—-.

. Job.number.

section.2.—-.

. manual.mode.

section.3.—-.

. automatic.mode.

section.4.—-

. reVieW.parameters.

when the servo is first started, and

has performed its startup procedure,

the first screen displayed should look

like this.

main.selection.menu:..................

. . F1=Job.num.F2=manual.

. . F3=automatic.(cYcle).

. . F4=reVieW.parameters.

*.select.F1=Job.num

The first step in programming a job is

to select a two digit job number which

will be used to store the parameters

that the operator inputs or to recall

an existing job number that was

previously loaded. when the operator

presses F1 on the keypad, the screen

will change to:

. Job.selection.menu.

. . enter.Job.number=____

. . press.F4.KeY.aFter.

. . correct.#.is.entered.

The next screen lets you program

parameters or exit with the existing

parameters.

. . Job.number.=.______

. . F1=prog..parameters

. . F4=don’t.alter.Values.

pressing the “F1 pRoG. pARAm-

eTeRS” key initiates the following

screen. key in the required param-

eters.

Feed.length=_________

. press.speed=_________

. Feed.angle=__________

*.once.the.parameters.haVe.

been.entered,.the.program.Will.

complete.the.math.routine.

Which.selects.the.proper.ac-

cel/decell.and.motor.speed.For.

the.parameters.listed.and.then.

the.main.menu.is.displaYed.

again.

*select.F2.manual

If the operator elects to move the

material from the feed to the die

electrically, the manual mode has to

be selected. pressing the F2 key will

bring up the manual mode screen.

. manual.length=_______

. F1=single_Feed

. F2=go.to.inch.mode

. F4=return

.......

each time the F1 key is pressed, the

servo will move the material the feed

length entered for the job number.

The material will move at the speed

required to keep up with the pro-

grammed press strokes per minute.

If the operator would like the material

to move a slower rate then the inch

mode should be selected. press F2

now to display the inch mode screen.

. .

. . inch.mode:

. . F1=Jog.ForWard

. . F2=Jog.reVerse

. . F4=return

when the F1 key is pressed, the feed

will advance the material at a slow

rate of speed. when the F2 key is

pressed, the feed will reverse the

material and run at a slow rate of

speed. press F4 to return to the main

screen.

with the main menu displayed and

pressing the “F3 AUTomATIC (Cy-

Cle)”, the following screen appears.

automatic....Job=01

. . Feed.length=______

. . press.speed=______

. . F4=return

In the automatic mode, the feed

length and operator entered press

speed will be displayed. whenever

the press mounted feed switch is

activated, the servo will feed the

feed length displayed on the screen.

because there is not an interface in

the control for the pilot release it will

be up to the customer to wire the pilot

release switch to the solenoid that

operates the raising of the rolls.

press F4 button to return to the main

menu and deactivate the automatic

control.

press F4 again and the final mode is

review parameters, the parameters

for the job number will then be dis-

played.

The last function on the keypad is the

“ReSeT Job pARAmeTeRS”. This

function should be used with special

Operator Input Section (cont.)