Introduction, The.cj.servo – Rapid-Air SERVO FEED: 104CJ, 108CJ, 106CJ, 112CJ User Manual

Page 3

The CJ servo has many features found

in the more expensive models. Some of

it’s features are:

input:

120 VAC, 50/60 HZ

.

amperage.required.at.input:

10 amps maximum.

.

accuracy:

.0025 per feed length at the rolls.

.

maximum.feed.length.input:

999.999 inches.

.

Job.storage:

99 jobs

.

display:

4 rows by 80 characters, backlit

.

.

INTRODUCTION

the.cJ.servo

The precision mechanical roll feed has

been designed for compactness, ease

of setup and installation. A 120 VAC

receptacle is all that is required of the

customer. Two cables are supplied with

the control and need to be connected

to the proper locations of the motor.

The electrical controls are housed in a

small box that can be mounted on the

press or if purchased, on a post that

can be positioned close to the press.

Fault.type:

Displayed on the drive if a fault occurs

otherwise an “8.” is displayed.

.

rolls:

Hardened and Ground.

.

drive.roll.parallelism.adjustment:

Used to tune the rolls to the material if

needed.

The Rapid-Air CJ feed uses the same

type of programming procedures as it

has in it’s more expensive models. Input

a feed length, strokes per minute, and a

feed arc and the program will adjust the

servo acceleration/deceleration and

maximum servo speed parameters

to the requirement needed to keep up

to the press strokes per minute.

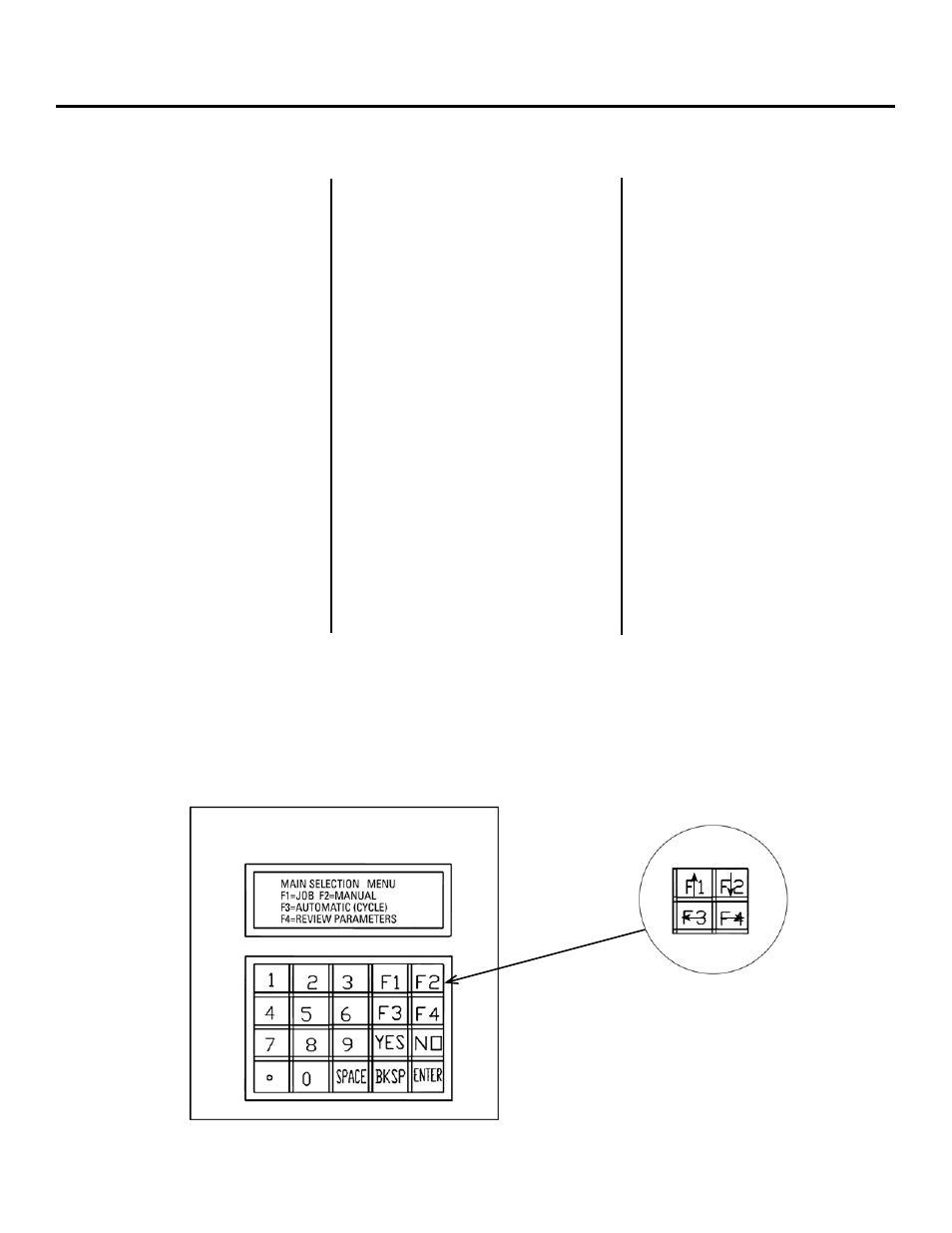

4 keyS weRe CHoSen To HAVe A

DoUble meAnInG, ARRowS AnD

“F” keyS. THe ARRowS weRe

bRoUGHT oUT AS THe pRImARy

InSTeAD oF THe “F” keyS. IF yoU

woUlD beAR wITH US, we ARe

lookInG AT A CoRReCTIon.

keypAD

note: