Installation and mechanical set-up, Rapid master installation, Mechanical set-up of die or punch – Rapid-Air AIR FEED / RAPID MASTER WITH KEYPAD User Manual

Page 3

The Rapid Master that you have just re-

ceived is fully assembled and ready to

be put into production. Due to shipment

vibration and handling, the machine

should be checked to ensure all screws

and bolts are tight. Remove the cover

to the electrical controls and visually

inspect that all parts are in place and

secure. If the machine was damaged

in shipment, contact the carrier first to

report the damage and then Rapid-Air.

CAUTION:

THE RAPID MASTER MACHINE IS TOP

HEAVY WHEN NOT SITTING ON ITS

BASE LEGS. USE EXTREME CAUTION

WHEN MOVING THIS MACHINE!

installation and mechanical set-up

rapid Master Installation

1) The customer must provide

minimum CFM – RE: chart, at 75

o 120 PSI of dry air to the machine.

Connect a minimum of 5/8” ID hose

into the filter regulator provided on

the machine. The inlet to the F-R-L

is a NPT female thread.

2) The customer must provide 120

volt, 20 amp, 60 cycle electrical

power. If an extension cord is

used between the source and the

machine, it should be a minimum

12 gauge wire to keep the voltage

loss down and for electrical

safety reasons.

Install machine on a level surface

with sufficient clearance for loading

and unloading process material.

The machine should be secured

to the floor through the 4 holes

provided in the feed of the machine

using 7/16 tie-down bolts. Or, can

be installed using 1/2-13 leveling

bolts and machine pads. The pads

keep the machine from walking

during operation and also act as a

noise reduction device.

The machine has two other

requirements that need attention

before putting the Rapid Master

into production.

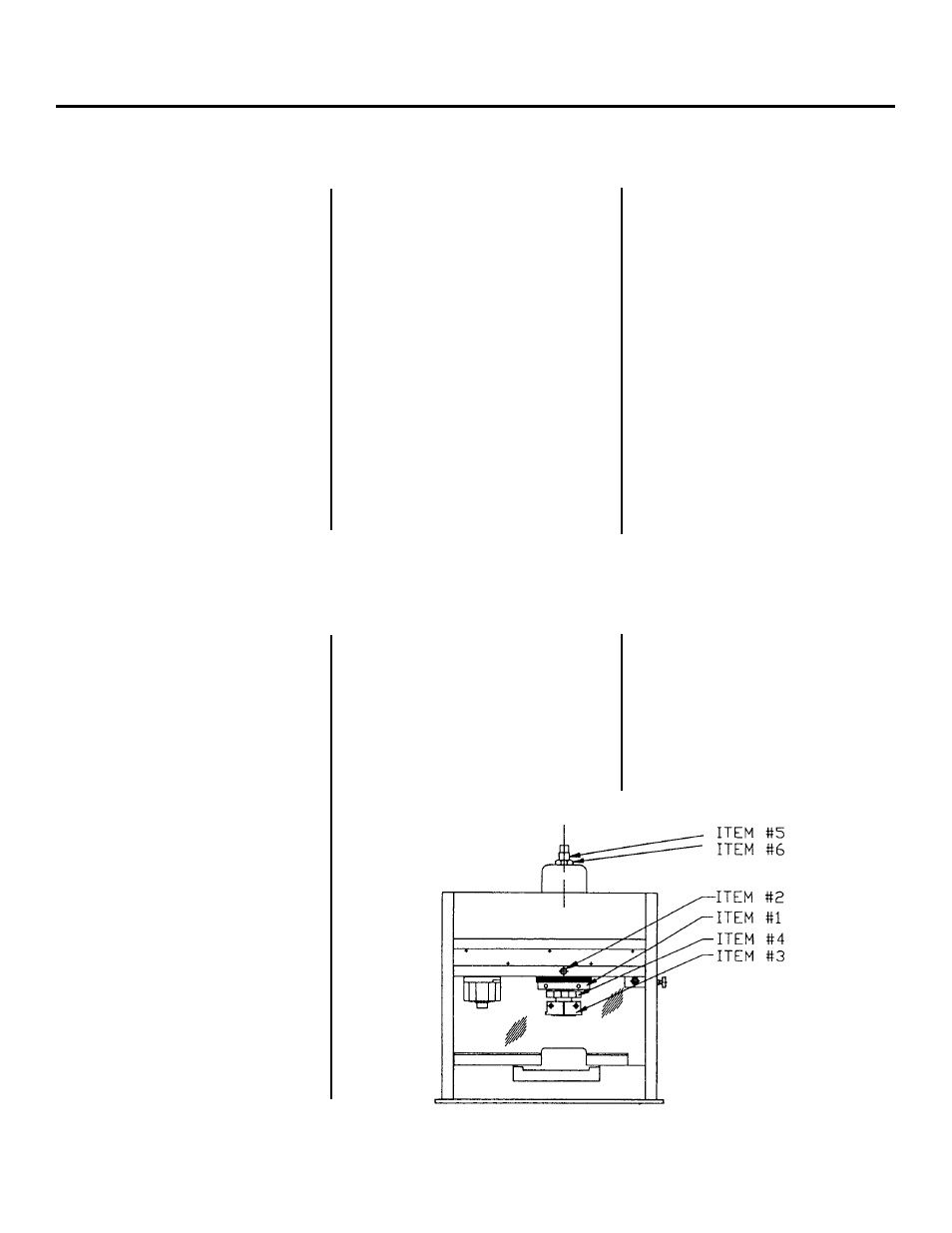

1) Secure the die set to the

bolster plate.

2) The piston adjustment sleeve

(item #1) establishes the stroke to

a maximum of .50 inches when

fully extended. The stroke is

reduced by 1.8 inches with each

full inward rotation, using the 3-3/4

spanner wrench provided. The

piston stroke adjustment sleeve is

locked in place with a nylon tipped

set screw (item #2).

3) Lift the punch holder plate and

loosely connect it to the inner shaft

ram adjustment screw with the

two half shell clamps (item #3)

provided.

4) Adjust the inner shaft (item #4) for

proper open height, using the

wrench provided.

5) Tightly secure the punch holder

plate to the inner shaft.

6) Lower the piston, piston shaft and

piston sleeve by rotating the

adjustment screw on top of the

head assembly (item #5) with the

crank provided. This is done to

check the full stroke set up. If all

adjustments are within limits, the

top adjustment screw should be

retracted to fully raise the piston

and ram assembly.

7) Lock the upper adjustment screw

(item #6) in the up position.

Mechanical Set-Up Of Die Or punch