Pumptec 114T SERIES User Manual

Page 7

7

Version 012313

Pumptec Operating Instructions and Parts Manual

PUMP SERIES 114T

MAINteNANce

DISASSEMblY AnD REASSEMblY

InSTRUCTIOnS (Refer to Schematic)

1. Remove pump from motor using a 3/16” hex wrench.

Remove remaining bolts from manifold of pump. Place

Manifold to side as a reference for re-assembly.

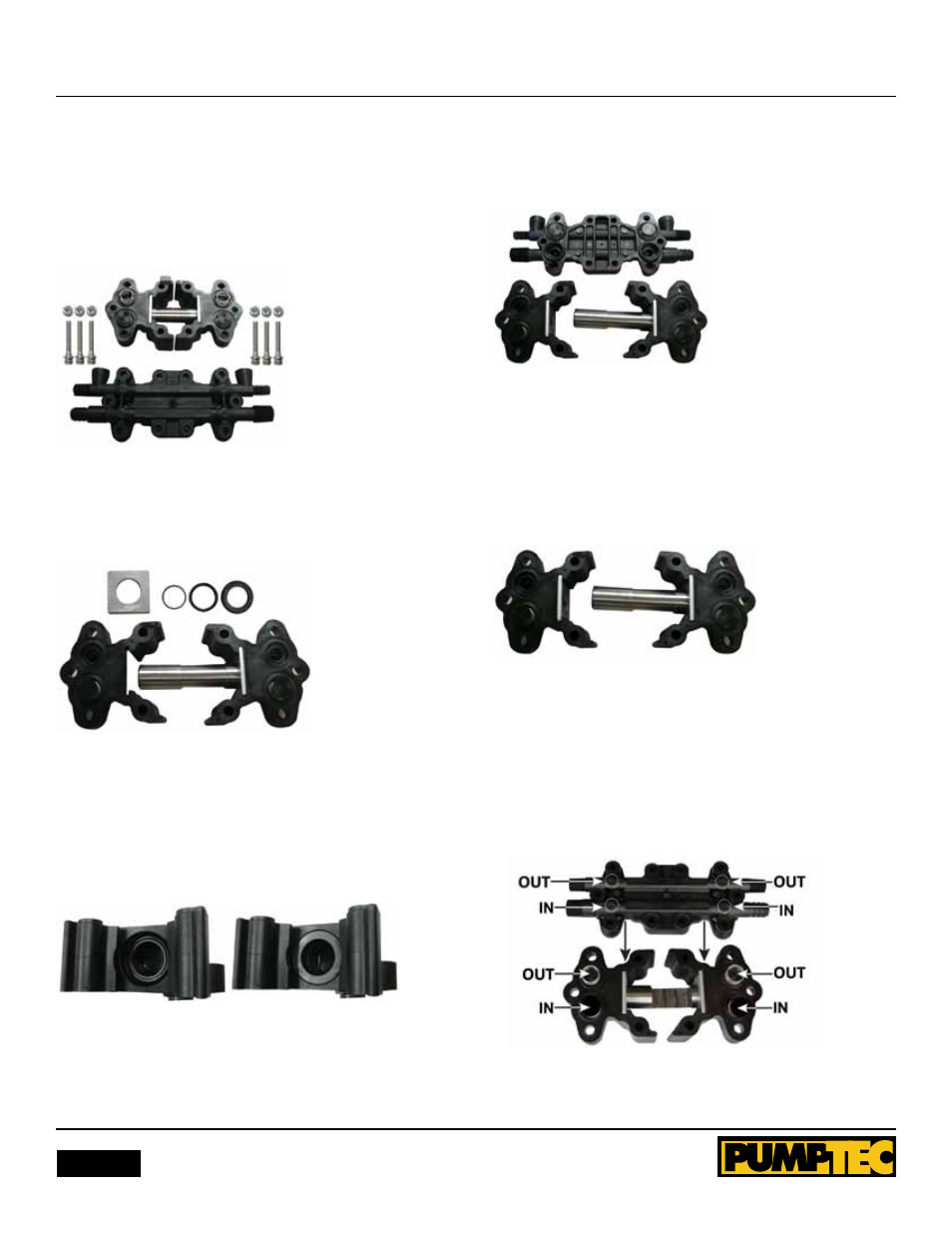

Figure 1

2. Holding each head, pull them apart to remove plunger.

Remove retaining plate from pump head. Remove internal seal

parts with finger. Discard parts.

Figure 2

3. Clean the head with a rag or towel. Inspect for damage or

excess corrosion. If the head is damaged, do not rebuild. note

the order and orientation of repair parts prior to installation.

4. Place o-ring around seal ring and gently place them into seal

bore.

Figure 3

5.

Place guide into seal bore, level above the o-ring seal

assembly. Apply even downward pressure to guide to install

seal and guide into seal bore. Remove guide and verify that

o-ring and seal are properly installed without bulges or

creasing. Slide the retaining plate back into place.

Figure 4

6. Repeat the previous steps 3-5 with the other head.

7. lightly grease the plunger with provided grease in small grey

tube. Slide plunger into one head assembly and then slide the

other head onto plunger. Place head and plunger assembly on

work surface with valves facing upward.

Figure 5

8. Adjust plunger slot position towards center and have slot

facing work surface. Replace all valves and o-rings that may

have fallen out during repair. Refer to image and manifold label

to understand proper orientation.

IMPortANt:

It is imparative the alignment of OUT/In

ports coincide with valves as indicated in Figure 6.

Figure 6