Powermate 009-0002CT User Manual

Page 5

5 - ENG

After each use:

Clean the surface with an air blaster or medium

bristle brush to remove any remaining abrasive material.

Always disconnect the tool from

the air supply before performing

any maintenance.

Changing ceramic nozzles:

Periodically (depending on the amount of grit accu-

mulated in the nozzle and the amount of use), the ceramic

nozzle will become worn, causing the spray to become

irregular or to stop.

1.

Disconnect the sandblaster from the air supply.

2.

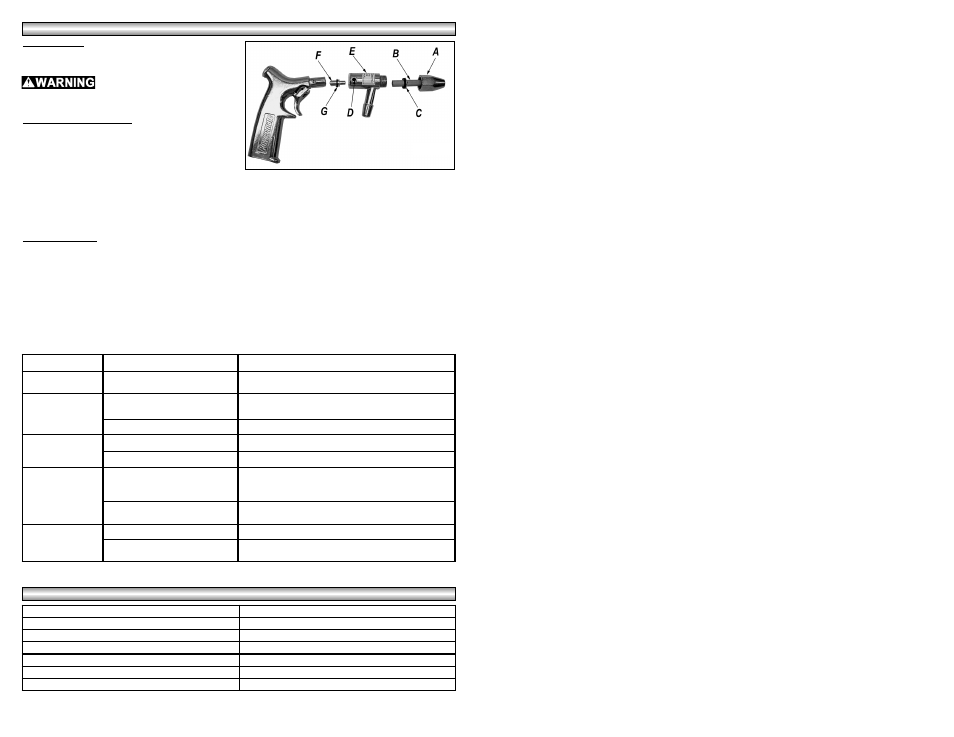

Remove the nozzle tip (A) and carefully pull out the ceramic nozzle (B) .

3.

Gently insert the new ceramic nozzle, being careful not to dislodge the internal tooth washer (C).

4.

Replace the nozzle tip (A).

NOTE: For replacement ceramic nozzles, contact Coleman® Powermate® at the number on the back of this

manual

Changing orifices:

Occasionally (after approximately 6-8 nozzle replacements), the nozzle orifice will need to be replaced.

1.

Disconnect the sandblaster from the air supply.

2.

Loosen the allen socket screw (D) from the tool with the hex key wrench (included).

3.

Remove the nozzle assembly (E).

4.

Remove the orifice (F). NOTE: If the orifice is stuck, tap the nozzle assembly lightly until the orifice is

dislodged.

5.

Place a new washer (G) on the new orifice (F).

6.

Gently drop the new orifice into the nozzle assembly.

7.

Reassemble the nozzle assembly and tighten the allen socket screw.

This sandblaster kit comes with standard 1/8”, 3/32” and 5/64” orifices.

USER-MAINTENANCE INSTRUCTIONS

USER-MAINTENANCE INSTRUCTIONS

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Sputtering-vacuum

leak

Damaged o-ring

Replace o-ring.

Gun does not spray

material

Wet or damp material

Replace wet abrasive material with dry material. Damp

material can be reused after it has dried.

Water in air lines

Drain compressor tank and install and in-line filter.

Sputtering-air/mate-

rial leaking at nozzle

tip area

Damaged o-ring

Replace o-ring.

Loose nozzle or orifice

Tighten nozzle tip or orifice (nozzle assembly).

Material slow out of

gun

Clogged siphon hose

Reduce the air pressure to 30 PSI and hold the gun

nozzle tip against a flat surface. Pull the trigger to force

any stuck material back out of the siphon hose.

Wet or damp material

Replace wet abrasive material with dry material. Damp

material can be reused after it has dried.

Sputtering-low vacu-

um

Worn orifice and/or ceramic nozzle Replace orifice and/or ceramic nozzle.

Abrasive material buildup around

orifice and/or ceramic nozzle

Remove and clean orifice and ceramic nozzle.

T

T

OOL

OOL

SPECIFICA

SPECIFICA

TIONS

TIONS

Average SCFM Requirements - 1/8” Orifice

6.0 SCFM @ 90 PSI

Average SCFM Requirements - 3/32” Orifice

3.0 SCFM @ 90 PSI

Average SCFM Requirements - 5/64” Orifice

1.5 SCFM @ 90 PSI

Air Inlet

1/4” NPT (female)

Siphon Hose

10 Feet

Recommended Hose Size

3/8”

Maximum Working Pressure

90 PSI

Figure 4