Powermate 009-0002CT User Manual

Page 4

4 - ENG

OPERA

OPERA

TING INSTRUCTIONS

TING INSTRUCTIONS

TYPICAL

TYPICAL

INST

INST

ALLA

ALLA

TION

TION

To begin using the tool:

1.

As a standard practice, drain water from the air

compressor tank and air lines prior to use each day

(reference your compressor operators manual for

detailed instructions). IMPORTANT: Installation of

appropriate water/oil removal equipment is

recommended. Failure to do so will cake the

abrasive material and clog the sandblasting gun,

causing the gun to not operate (follow the

recommended installation for the spray gun in

Figure 1).

2.

Install a 1/4” NPT male connector (not included) into the

air inlet port on the tool (see Figure 2). Note: Use

Teflon® Tape on all threaded connections.

3.

Turn on the air compressor and allow it to build up

pressure.

4.

Adjust the air compressor’s regulator or the supply line regulator to 90 PSI.

Assembly:

1.

Push one end of the siphon hose onto the small end of the

metal aspirator tube (see Figure 3). NOTE: Do not push the

siphon hose all the way onto the aspirator tube, only push

on about an inch.

2.

Push the other end of the siphon hose onto the vacuum tube

(See Figure 3).

3.

Insert the aspirator tube into the abrasive material, making

sure that the shorter tube remains above the material (the tube

can be placed directly into the bag). Silica (playground sand) or

hard sand, ground nut shells or aluminum oxide carbide are all

abrasive materials that can be used. NOTE: Make sure that

the abrasive material is dry.

4.

Connect the tool to the air hose quick coupler. NOTE: It is recommended that a whip hose with a swivel

(P012-0079SP - not included) be used to prevent twisting, kinking and excessive wear to the air hose

(ref. item “F” in figure 1 for recommended connections).

Always disconnect the sandblaster from the air supply before changing accessories,

relocating or performing any maintenance.

5.

To start sandblasting, gently pull back on the trigger using smooth and even strokes accross the blasting

surface. NOTE: The nozzle should be positioned at an angle to the surface being sandblasted rather

than perpendicular, to reduce work surface material from rebounding back at you.

Risk of Injection. The high pressure and abrasive materials that are used during

sandblasting can penetrate skin and cuase serioius injury. Wear ANSI A87.1

approved safety glasses or face shield, gloves and a MSHA/NIOSH approved

resiprator during operation. Always direct spray away from self and others or

serious injury could occur.

6.

To stop sandblasting, release the trigger.

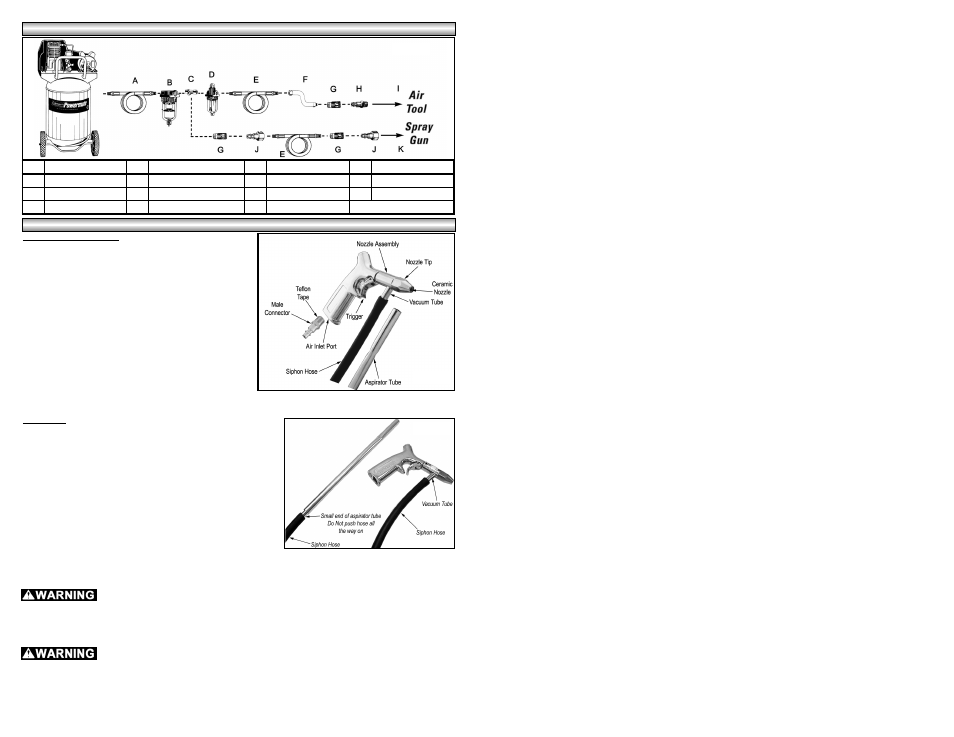

Key

Description

Key

Description

Key

Description

Key

Description

A

Air hose

D

In-line Oiler

G

Quick Coupler

J

Female Connector

B

In-line Filter

E

Air Hose

H

Male Connector

K

Spray Gun

C

Tee Fitting

F

Whip Hose

I

Air Tool

Figure 1

Figure 2

Figure 3