Paasche Airbrush AB-PL User Manual

Page 3

Paasche AB (Fine Art) Airbrush Instructions and Parts List

Page 3

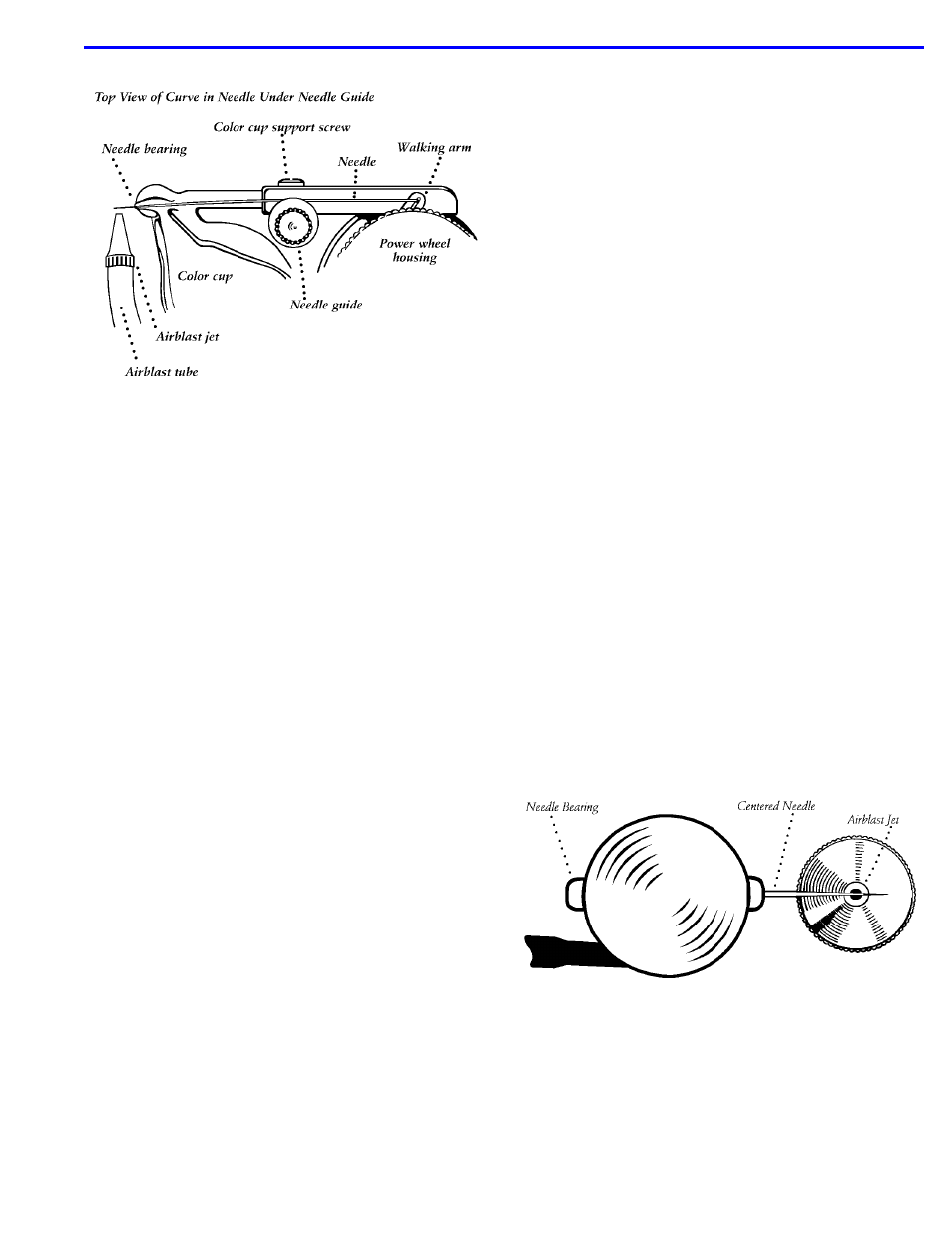

SHAPING THE NEEDLE (Continued from page 2):

The other curve of the needle (top view) is the one that

varies most from airbrush to airbrush. Again, there should

be a gradual curve, with a straight section at the tip of the

needle. The idea is to curve the needle completely under

the lip of the needle guide (if the needle rides at the edge

of the lip, the needle will not stay in place as it oscillates),

and at the same time for the tip of the needle to ride

nearly parallel with the edges of the slot in the needle

bearing. It is normal for the tip of the needle to sit at a

slight angle in the needle bearing—with the curve in the

needle, you can’t help it. But this angle should be

minimized, to keep the needle from binding in the needle

bearing.

ADJUSTING THE COLOR CUP:

The color cup is clamped into the color cup support by

tightening the screw on the front side of the support. To

determine how far the color cup should project from the

support, first run the Finger Lever Adjusting Screw out

(counter-clockwise) until there is just a “hair’s breadth”

remaining between the butt end of the needle and the end

of the slot in the walking arm. This finger lever position is

called the “farthest forward rest position.”

Now slide the color cup in or out of the support until the

tip of the needle comes to the end of the slot in the

needle bearing but does not project from it. Attach the AB

to your air compressor and start the needle moving with

the finger lever in the “farthest forward rest position”

(push down the lever but do not pull back). Slide the color

cup out until the needle does not project from the

bearing—you now have the correct color cup position for

the “farthest forward rest position.” Note: The rapidly

moving tip is easier to see against a white background.

The color cup can also be partially rotated to allow you

to spray onto a surface more or less horizontally. You will

notice as you rotate the color cup, the position of the

needle bearing changes, necessitating a readjustment of

the airblast tube and in a few instances even a

recurvature of the needle. For this reason you will

probably want to find one position for the color cup which

is comfortable for you and then stick with it. The amount

of tilt is limited, from a position in line with the power

wheel housing to about 30 degrees below this line.

AIR VALVE PARTS REPLACEMENT:

This is rarely necessary, but these parts can be

replaced fairly simply. Unscrew the valve nut and remove

the spring plunger, and washer in that order. Use a small

stiff wire with a slight hook bent into the end of it to fish

out the washer. Then place a new washer on the plunger

and insert the plunger and washer together. To avoid

compressing the springs too far, screw the valve nut in

only until it is slightly below the level of the air valve

casing.

ADJUSTING THE AIRBLAST TUBE:

Check that the color cup is properly positioned as

described above. With pliers loosen the locknut where the

airblast tube attaches to the body of the airbrush. Now

rotate the airblast tube, screwing it in (counter-clockwise)

or out (clockwise) until the airblast jet is about 1/64 inch

from the end of the needle bearing. Now with the air

turned off pull back the finger lever so that the needle is

pushed out in front of the airblast jet. The distance from

the needle to the tip of the jet should be about 1/64 inch.

Very carefully you may bend, if necessary, the airblast

tube where it enters the locknut and arches to the body of

the airbrush to accomplish this second adjustment. Do

not bend at the elbow of the airbrush tube or in front of

the elbow for two reasons: (1) curved tubing such as the

elbow in the airblast tube is inherently more brittle and

tends to crack if leverage is applied to it, and (2) there is a

soldered joint where the stipple adjuster is attached to the

elbow, which may break if pressure is applied.

Finally set the airblast tube so that the needle, when

extend ed, passes through the center of the airstream

from the airblast jet—that is, as you sight down the hole in

the airblast jet, the needle should cross the center of that

hole. If the needle is off center, you will get a stippling

effect, and for some applications you may wish to set the

airblast tube in this way purposely.

The “AB” Airbrush is not suitable for use with alcohol or

lacquer colors. Any water color, opaque or oil can be used with

brilliant results.

See Page 4 for AB Replacement Parts and Parts Numbers.