Paasche Airbrush AB-PL User Manual

Page 2

Page 2

Paasche AB (Fine Art) Airbrush Instructions and Parts List

BASIC PRECAUTIONS:

Before starting any adjustments or parts replacements,

a couple of precautions should be observed. The fine tip of

the needle is very delicate, and once damaged it is difficult

to straighten again. Remove the needle before beginning a

repair, or if necessary use an old needle. Secondly, most

of the threaded parts are made of brass, and the threads

are easily stripped. Do not force the parts to do what they

don’t want to do.

(See section “Speed Regulator Screw” for specific

example of this problem.)

ADJUSTING STIPPLE ADJUSTER & AIRBLAST JET:

The stipple adjuster is the screw at the elbow of the

airblast tube. It controls the airflow through the airblast

tube. By turning this screw in (clockwise), you restrict the

volume of air blown out the airblast jet and across the

needle. When the air is almost shut off you create a grainy,

stippling effect.

The threads of the stipple screw can become so loose

that it will not hold its position in the airblast tube and will

gradually turn out as you use the airbrush. As a preventive

measure, we suggest you avoid excessive turning in and

out of this screw. From the fully closed position, you only

need to turn the screw two full turns to fully open this little

valve.

If the screw is too loose, you can tighten the threads’ fit

by pressing a dab of beeswax onto the threads and rolling

the screw between your thumb and forefinger to work the

beeswax into the threads. Only a thin coating is needed.

Then pass the screw very briefly over a match flame,

melting the beeswax into the threads. The wax will adhere

better as you insert the screw back into the airblast tube.

SPEED REGULATOR SCREW:

This screw works much the same as the stipple

adjuster. It controls airflow and thus the speed of the

power wheel and the needle. Again, all the adjustments

happen within a range of two turns of the screw. As noted

before, do not try to force the screw tighter than it wants to

go. You can shear the head of the screw right off, leaving

the screw firmly embedded in the body of the airbrush,

impossible to remove.

POWER WHEEL TOP SHAFT BEARING ADJUSTING:

Adjusting shaft bearings is a procedure that should be

done only if the power wheel is sluggish, is intermittently

binding, or is completely stuck. To check this, remove the

needle, then try to operate the power wheel and walking

arm, pressing down the finger lever and moving it back

and forth. If the power wheel runs smoothly now, the

problem is with your needle, not with the bearing

adjustments. If the problem continues, however, you will

need to adjust the bearings. If the power wheel is sluggish

or will not move at all, it could be that you simply need to

loosen the top bearing a little. Remove the top grease cap,

exposing the top shaft bearing. You will find the bearing

covered with grease, which you may want to remove in

order to see the slot in the top of the bearing better. To

adjust the bearing, use a screwdriver with a blade as wide

as the opening into which the bearing fits. A larger

screwdriver can be filed down to fit exactly the slot in the

bearing. While pressing down on the finger lever for air,

slowly loosen the top bearing (turn counter-clockwise). If

the power wheel frees itself and begins to run smoothly,

you have found the problem. To adjust the bearing

accurately, tighten it again until the power wheel stops,

then loosen it just until the power wheel runs smoothly.

This is a matter of 1/16 to 1/8 turn, never more than 1/4

turn. Do not loosen the bearing beyond the point where the

power wheel frees itself and runs smoothly. Beyond this

point the power wheel will begin to vibrate in the bearing. It

will appear to be running smoothly but then will suddenly

bog down. If this happens, tighten the bearing a little. You

will find the power wheel returns to normal speed.

If you find that the power wheel runs smoothly for a

while then freezes up again, the problem is that the

threads in the power wheel cover have become too worn

to hold the bearing snugly in place. The power wheel

happens to spin in the same direction needed to tighten

the top shaft bearing. If the bearing does not fit snugly in

the power wheel cover, the power wheel will actually drag

the bearing until it stops the power wheel! The remedy for

this situation is the same as for the loose stipple adjuster

or speed control—work beeswax into the threads of the

bearing. Over a long time period, the beeswax will wear

out and this repair will have to be done again.

FINGER LEVER ADJUSTING SCREW:

This screw is located at the back of the finger lever, in

the lever fork, and adjusts the “rest position” of the finger

lever. When you turn the adjusting screw in, the walking

arm is pushed farther into the stream of air from the

airblast jet. By adjusting this screw you set the width of the

line created when the finger lever is simply depressed, but

not pulled back (the “rest position” spray width.) Note: In

the “farthest forward rest position” you get no spray if the

color cup is properly positioned.

Be careful with the two extremes of this adjustment. If

you turn the adjusting screw too far out (counter-

clockwise), the needle moves to the very end of the slot in

the walking arm, and the needle binds between this slot

and the slot in the color cup support. Always check that the

needle is at least a “hair’s breadth” from the very end of

the walking arm slot.

On some ABs, if you turn the adjusting screw too far in

(clockwise), the walking arm will be pushed too far forward

and will hit the front of the opening in the power wheel

cover through which it extends.

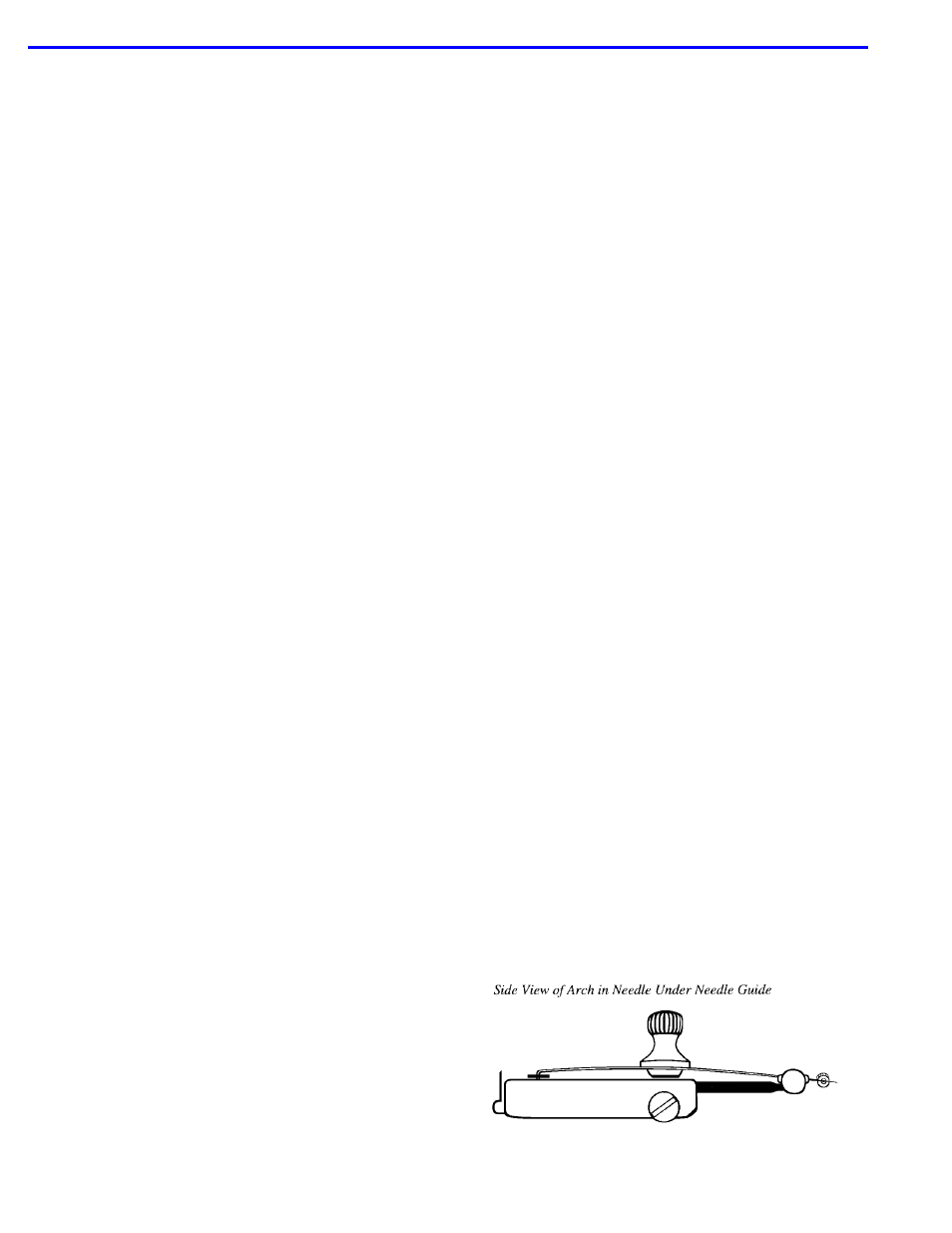

SHAPING THE NEEDLE:

In general an AB needle should be curved in two

directions. Viewed from the side the needle should have a

slight arch, so that the needle guide can hold it firmly in the

slot in the needle bearing. Viewed from the top, the needle

should curve underneath the lip of the needle guide screw.

Both arch and curve should be gradual bends along the

length of the needle, with no sudden bends or angles.

About 3/8 inch at the tip of the needle—that portion which

rides in and out of the needle bearing—should be left

straight. In fact, try not to touch the tip at all as you are

arching and curving the needle, for fear of distorting the

needle. Remember that you are shaping the needle to fit

your particular airbrush.

The arch (side view) of the needle does not need to be

too great—just enough to give a little tension when the

needle guide is screwed all the way down. With a more

extreme arch the tip of the needle rides in the bearing at

too great an angle. In addition, the motion of the needle is

not as smooth, because the crest of the arch is passing in

and out from under the needle guide.

Continued on page 3