Cartridge operation/features, Shade guide settings – Lincoln Electric IM10055 AUTO-DARKENING HELMET User Manual

Page 7

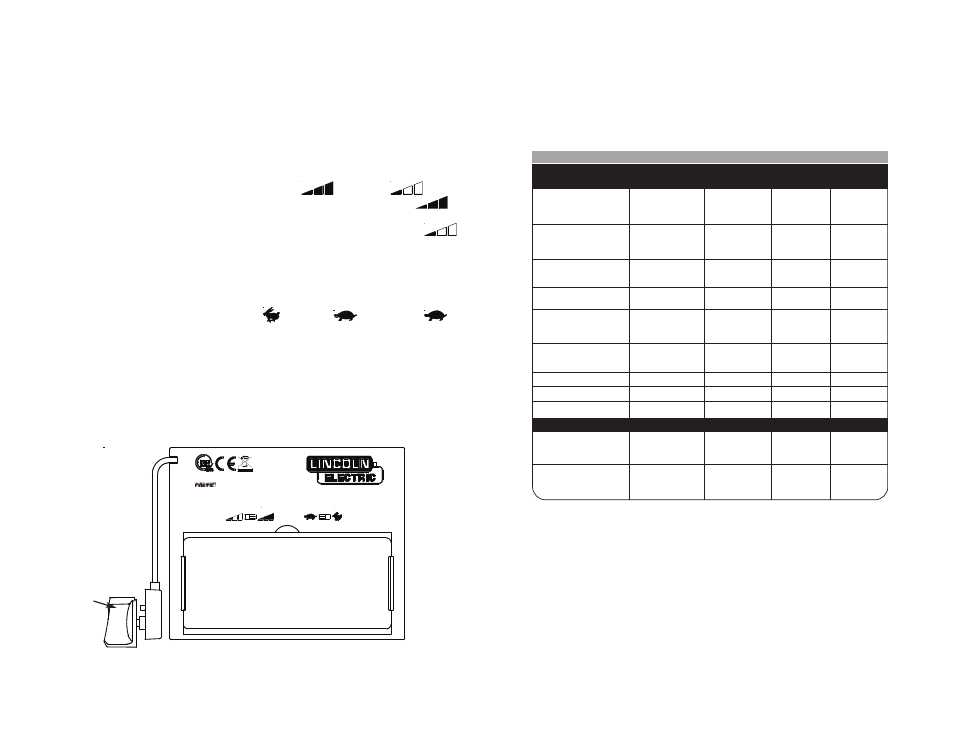

CARTRIDGE OPERATION/FEATURES

Variable Shade Control

The shade can be adjusted from shade 9 to 13 based upon welding process or

application (refer to Shade selection chart on page 6). The variable shade control

knob is mounted to shell for external adjustment.

Sensitivity Control

You can adjust the light sensor by selecting the (High) or (Low)

position of the sensitivity switch as shown in figure below. Generally, the

(High) setting is selected for normal use. Where the helmet is used in the pres-

ence of excess ambient light or with another welding machine close by, the

(Low) setting may be selected for better performance.

Delay Time Control

This control is designed to protect the welder’s eyes from the strong residual rays

after welding. You can delay the time of change to light state from the darkened

state with setting delay control switch on (Fast) or (Slow). The

(Slow) setting is recommended for high amperage applications where the weld

puddle is still very bright after the welding arc has ceased and for situations

where the filter may be temporarily blocked from seeing the welding arc.

Solar Power

This helmet is powered by solar energy. As such, there is no battery that requires

replacement.

Variable shade

control Knob

5

ALWAYS TEST TO BE SURE THE ADF CARTRIDGE IS CHARGED

BEFORE WELDING. The helmet can be placed in sunlight to charge. Do

not store the helmet in a dark cabinet or other storage area for long periods.

While welding, the arc also charges the ADF cartridge.

SHADE GUIDE SETTINGS

If your helmet does not include any one of the shades referenced above, it is

recommended you use the next darker shade.

6

SS27

279978

78--55 ((600

600SS))

®

®

44//9-

9-13

13 11//22//11//22//37

3799 C

CEE D

DIIN

N

TTM

M ZZ8877

C

CAAN

N/C

/CSA

SA ZZ94

94..33

LLAABBSS

SE

SEN

NSSIIB

BIILLIITTEE

SE

SEN

NSSIIB

BIILLIID

DA

AD

D

SE

SEN

NSSIITTIIVVIITTYY

TTEEM

MPS

PS D

DEE D

DEELLA

AII

TTIIEEM

MPPO

O D

DEE R

REETTA

AR

RD

DO

O

TTIIM

MEE D

DEELLA

AYY

S

S27

279

978

78--5

5 ((600

600S

S))

®

®

4

4//9-

9-13

13 1

1//2

2//1

1//2

2//37

379

9 C

CE

E D

DIIN

N

T

TM

M Z

Z8

87

7

C

CA

AN

N/C

/CSA

SA Z

Z94

94..3

3

L

LA

AB

BS

S

SE

SEN

NS

SIIB

BIIL

LIIT

TE

E

SE

SEN

NS

SIIB

BIIL

LIID

DA

AD

D

SE

SEN

NS

SIIT

TIIV

VIIT

TY

Y

T

TE

EM

MPS

PS D

DE

E D

DE

EL

LA

AII

T

TIIE

EM

MP

PO

O D

DE

E R

RE

ET

TA

AR

RD

DO

O

T

TIIM

ME

E D

DE

EL

LA

AY

Y

GUIDE FOR SHADE NUMBERS

OPERATION

ELECTRODE SIZE

ARC

MINIMUM

SUGGESTED(1)

1/32 in. (mm)

CURRENT (A)

PROTECTIVE

SHADE NO.

SHADE

(COMFORT)

Shielded metal arc

Less than 3 (2.5)

Less than 60

7

–

welding

3-5 (2.5–4)

60-160

8

10

5-8 (4–6.4)

160-250

10

12

More than 8 (6.4)

250-550

11

14

Gas metal arc

Less than 60

7

–

welding and flux

60-160

10

11

cored arc welding

160-250

10

12

250-500

10

14

Gas tungsten arc

Less than 50

8

10

welding

50-150

8

12

150-500

10

14

Air carbon

(Light)

Less than 500

10

12

Arc cutting

(Heavy)

500-1000

11

14

Plasma arc welding

Less than 20

6

6 to 8

20-100

8

10

100-400

10

12

400-800

11

14

Plasma arc cutting

(Light)

(2)

(2)

(2)

Less than 300

8

9

(Medium)

300-400

9

12

(Heavy)

400-800

10

14

Torch brazing

–

–

3 or 4

Torch soldering

–

–

2

Carbon arc welding

–

–

14

PLATE THICKNESS

in.

mm

Gas welding

Light

Under 1/8

Under 3.2

4 or 5

Medium

1/8 to 1/2

3.2 to 12.7

5 or 6

Heavy

Over 1/2

Over 12.7

6 or 8

Oxygen cutting

Light

Under 1

Under 25

3 or 4

Medium

1 to 6

25 to 150

4 or 5

Heavy

Over 6

Over 150

5 or 6

(

1) As a rule of thumb, start with a shade that is too dark, then go to a lighter shade which gives sufficient view of the weld zone without going

below the minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs

the yellow or sodium line the visible light of the (spectrum) operation

(2) These values apply where the actual arc is clearly seen. Experience has shown that lighter filters may be used when the arc is hidden by the

workpiece.

.

Data from ANSI Z49.1-2005

GUIDE FOR SHADE NUMBERS

OPERATION

ELECTRODE SIZE

ARC

MINIMUM

SUGGESTED(1)

1/32 in. (mm)

CURRENT (A)

PROTECTIVE

SHADE NO.

SHADE

(COMFORT)

Shielded metal arc

Less than 3 (2.5)

Less than 60

7

–

welding

3-5 (2.5–4)

60-160

8

10

5-8 (4–6.4)

160-250

10

12

More than 8 (6.4)

250-550

11

14

Gas metal arc

Less than 60

7

–

welding and flux

60-160

10

11

cored arc welding

160-250

10

12

250-500

10

14

Gas tungsten arc

Less than 50

8

10

welding

50-150

8

12

150-500

10

14

Air carbon

(Light)

Less than 500

10

12

Arc cutting

(Heavy)

500-1000

11

14

Plasma arc welding

Less than 20

6

6 to 8

20-100

8

10

100-400

10

12

400-800

11

14

Plasma arc cutting

(Light)

(2)

(2)

(2)

Less than 300

8

9

(Medium)

300-400

9

12

(Heavy)

400-800

10

14

Torch brazing

–

–

3 or 4

Torch soldering

–

–

2

Carbon arc welding

–

–

14

PLATE THICKNESS

in.

mm

Gas welding

Light

Under 1/8

Under 3.2

4 or 5

Medium

1/8 to 1/2

3.2 to 12.7

5 or 6

Heavy

Over 1/2

Over 12.7

6 or 8

Oxygen cutting

Light

Under 1

Under 25

3 or 4

Medium

1 to 6

25 to 150

4 or 5

Heavy

Over 6

Over 150

5 or 6

(

1)

As a rule of thumb, start with a shade that is too dark, then go to a lighter shade which gives sufficient view of the weld zone without going

below the minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs

the yellow or sodium line the visible light of the (spectrum) operation

(2)

These values apply where the actual arc is clearly seen. Experience has shown that lighter filters may be used when the arc is hidden by the

workpiece.

.

Data from ANSI Z49.1-2005