Oven service procedures, Temperature control programming procedure – XLT XD-9006A (GAS Oven Version – C, AVI Hood Version – C) User Manual

Page 21

21

Technical Support US: 888-443-2751

Technical Support INTL: 316-943-2751

Temperature Control Programming Procedure

OVEN SERVICE PROCEDURES

Ser1

OFF

P1

5˚C/22˚F

P3

0

P4

315˚C/600˚F

P5

reU

P6

4-20

P9

AL1.P

P10

H.A.

P11

nonE

P16

0

P17

SFtA

P18

norL

P19

norL

P24

reU

P25

OFF

P28

0

P29

0n

P30

0

P34

OFF

P36

tn.30

P37

0

P39

n0FL

P41

P.I.d.

P42

10.0

P43

Fn.SP

P44

0

SP

260°C/500°F

SP2

0

nnn 3111/OFF

AL1

315°C/600°F

HSA1

0.1

Pb

5.0

ti

5.00

td

0.00

1P

30.0

rL

204°C/400°F

rH

310˚C/590°F

Grd1

InF

Grd2

InF

OLH

100.00

toL

InF

rnP

InF

Figure 4

Figure 2

Figure 3

Read the entire instruction before programming.

TIP

Configuration Button Functions

display advances to the next parameter. This is required be

tween

each

parameter.

UP=

Increases the setting of the selected parameter.

DOWN=Decrease the setting of the selected parameter.

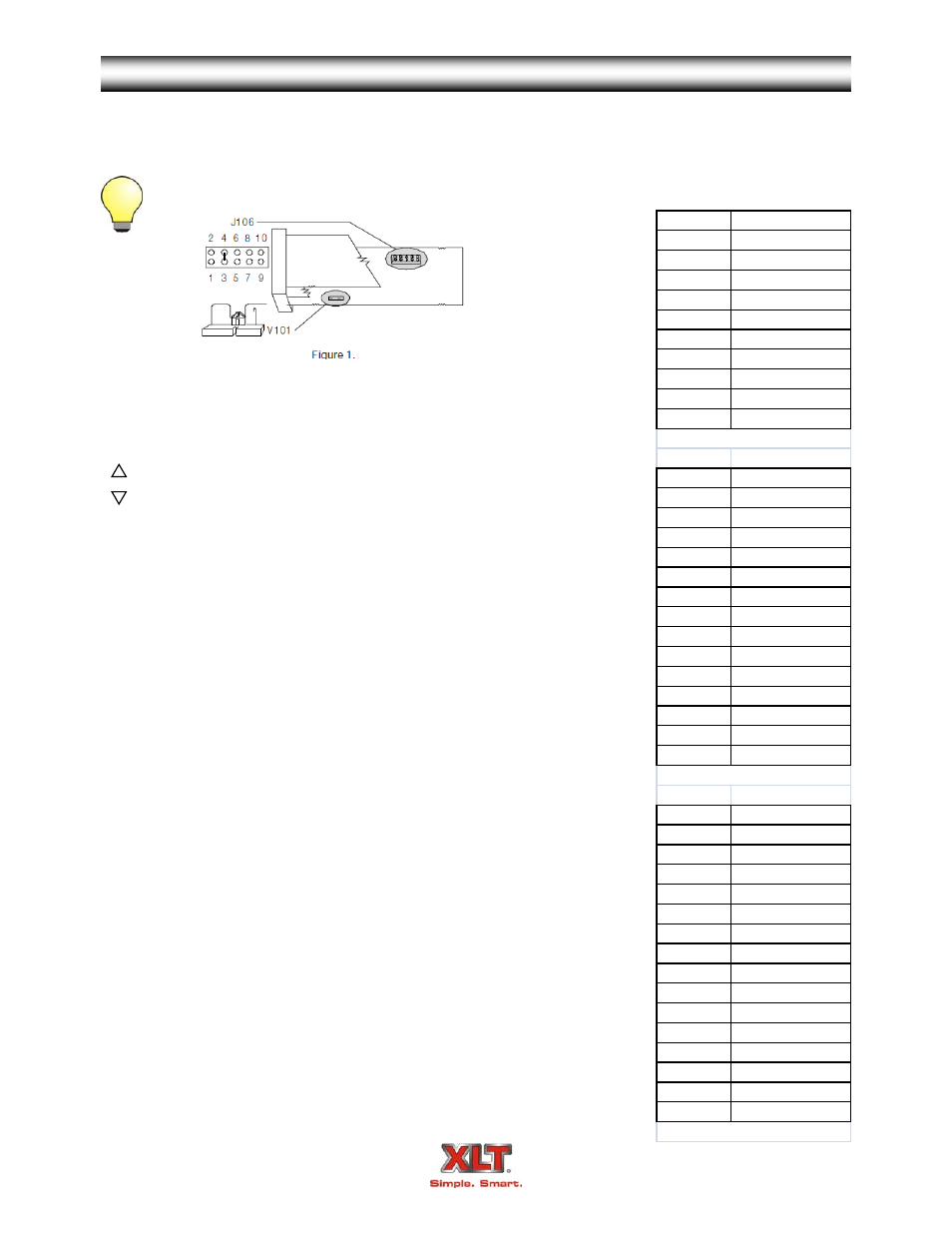

1. Open V101 switch for Basic/Advanced Configuration (Figure 1)

Remove instrument from its case

Open switch V101

Verify that jumper J106, is configured as shown

Re-insert the instrument back in its case

2. Basic

Configurations

Using the configuration buttons, scroll through parameter codes,

changing them to match (Figure 2)

After P17 _._._._. Will appear

Using the configuration buttons scroll to 262 and press

to enter Advanced Configurations

3. Advanced Configuration Procedure

Using the configuration buttons scroll through parameter codes

changing them to match (Figure 3)

4. Close V101 switch after Basic/Advanced Configuration (Figure 1)

Remove instrument from its case

Close Switch V101

Re-insert the instrument back in its case

5. Operating Parameters Procedure (Figure 4)

On the first pass through change nnn to 3111 to unlock the ad

vanced

configuration

Scroll through the parameter codes again and change the nnn to

5 this locks the advanced configuration

Scroll through the parameter codes again and verify nnn in ON