Kx-t dough divider/rounder, Features, Benefits – AMF Dough Divider/Rounder KX-T User Manual

Page 2: Mechanical features

KX-T DOUGH DIVIDER/ROUNDER

Auger

•

Large 8” (203 mm) UHMW single auger gently urges dough

to the metering pump

•

Strong 8” (203 mm) stainless steel pump housing for long

service life

•

No dusting flour needed for dividing or rounding

•

250 lb. (113 kg) capacity stainless steel hopper

− Round design ensures dough has no corners

to hang on

− First in/first out flow design

− Easy to clean

•

Simple open stainless steel frame design for easy access

and sanitation

•

Metering pump and manifold mounted on separate cart

provides easy access for sanitation and maintenance

•

Heavy duty, hollow shaft Nord direct auger drive

•

No chains on the entire machine

− No operating maintenance adjustments required

− Extremely low maintenance

•

Large 8” (203 mm) coupling drive allows auger to be

removed in seconds

•

Entire design provides slow, simple rotary motions

ensuring long service life with low maintenance costs

FEATURES

&

BENEFITS

Scaling Accuracy

•

Stainless steel metering pump provides greater scaling

accuracy than conventional volumetric dividers

•

Low pressure manifold with individual port control valves

provides estimated ±1% accuracy

Low Maintenance

•

Simple design with slow rotating parts requires very little

maintenance

•

Machine can be run for weeks with no required

maintenance downtime

Easy Sanitation

•

CIP system controlled by the PLC program efficiently cleans

all internal product areas

•

Complete visual inspection of entire dough path can be

performed in minutes with no tools

Simple Set-up with Recipe Management

•

Change products with the push of a button, adjust

machine scaling in seconds

•

No change over parts required for different size

products

Efficient Design and Lower Cost

•

Small footprint can replace conventional dividers

•

Lower purchase price, low maintenance, no divider oil,

all add up to lower operating cost

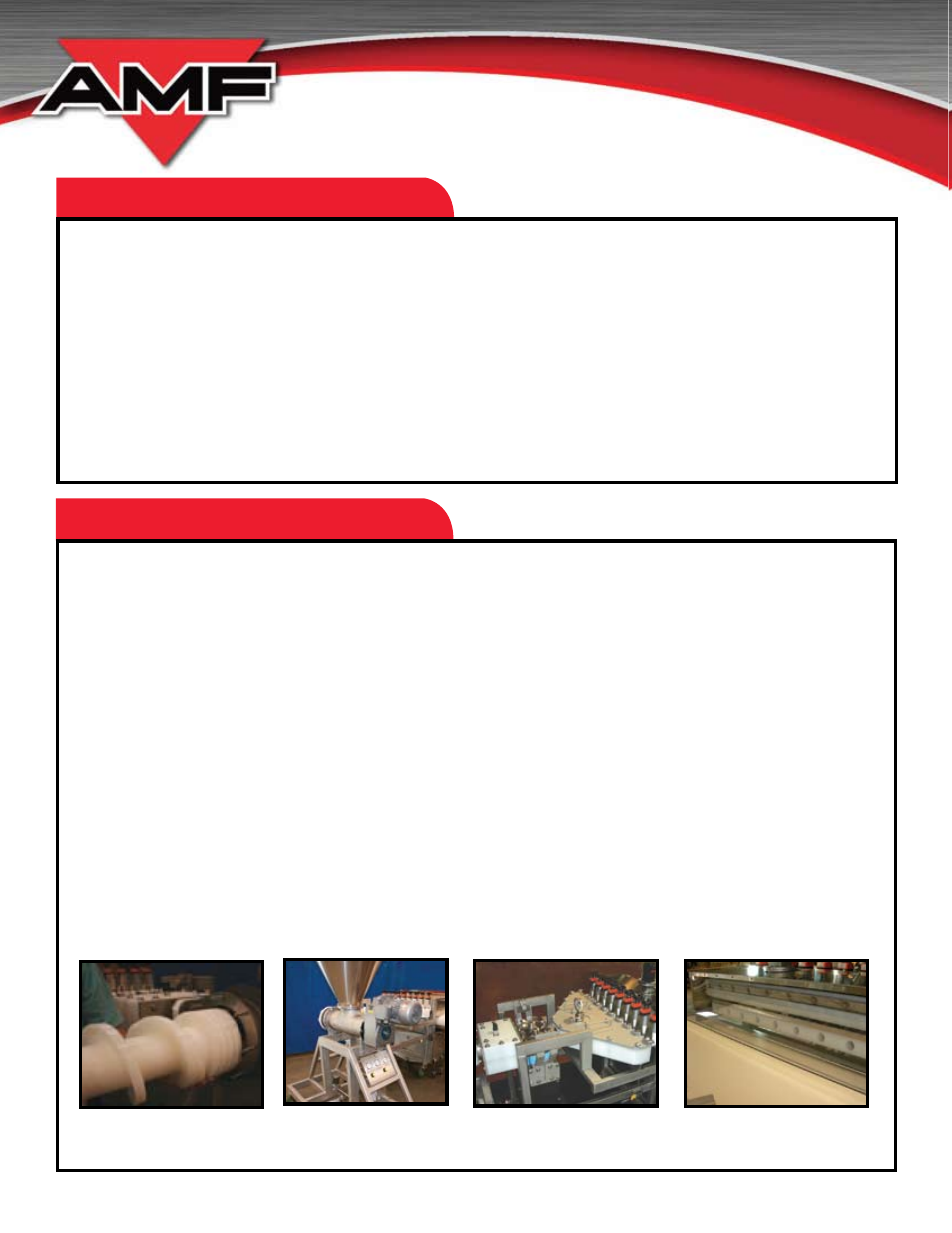

MECHANICAL FEATURES

Main Frame Area

& Vacuum System

Metering Pump, Manifold,

and Valves

Servo Rotary Cut-off

•

Venturi generator based vacuum system for positive

pumping action and thorough degassing

•

Auger speed controlled by pressure feedback loop for

accurate throughput

•

Dependable Waukesha stainless steel metering pump

with 3” (76 mm) outlet

•

UHMW "Quick Clean" scaling division manifold

available in 4, 5, 6, 8, or 9 pocket configuration

•

Individual stainless steel control valves on each port

provide simple, precise scaling control

•

UHMW cut-off knife

− For precise cutting motion up to 110 cuts per

minute

− Optional rotary high speed cut-off for speeds

up to 200 cuts per minute

•

Dividing system requires no divider oil

•

Divider unit mounted on heavy duty casters

•

Stainless steel rounder frame with direct Eurodrive on

belt

•

Grooved UHMW rounder bars with AMF floating foot

•

Divider can be assembled in either LH or RH

configuration

•

Rounder must be specified LH or RH