Jackco Model 65500A User Manual

Page 5

Caution: To prevent personal injury, all inspection, maintenance, and repair

procedures must be performed when the jack is free of load.

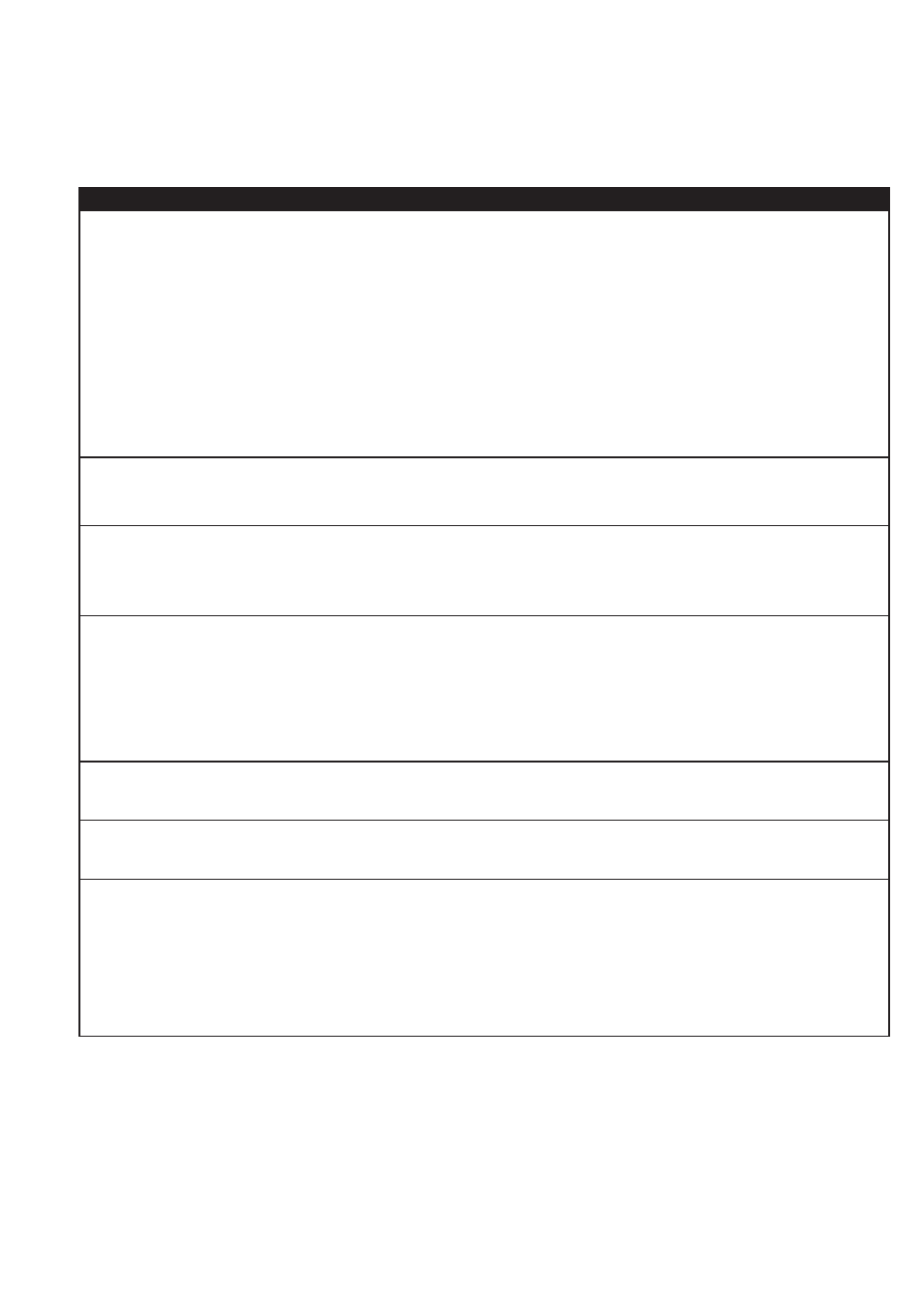

TROUBLESHOOTING

Trouble

Cause

Solution

Jack does not lift

1. Release valve is open

2. Low/ no oil in reservoir

3. Air-locked system

4. Load is above capacity of jack.

5. Delivery vale and/or bypass

valve not working correctly.

6. Packing worn out of defective.

7. Leak in air line

8. Inadequate air pressure.

1. Close release valve.

2. Fill with oil and bleed system.

3. Bleed system.

4. Use correct equipment.

5. Clean to remove dirt or foreign

matter. Replace oil.

6. Install seal kit.

7. Locate leak; tighten

connections

8 Set air pressure to 85-120 psi

Jack lifts only partially

1.too much or not enough oil

1.Check oil level

Jack advances slowly

1. Pump not working correctly.

2. Leaking seals.

1. Install seal kit, or replace power

unit.

2. Install seal kit.

Jack lifts load, but

doesn’t hold

1. Cylinder packing is leaking.

2.Valve not working correctly

(suction, delivery, release, or

bypass)

3. Air-locked system.

1. Install seal kit.

2. Inspect Calves. Clean and

repair seat surfaces.

3. Bleed system.

Jack leaks oil

1. worn or damaged seals

1. install seal kit

Jack Will not retrack

1. Release valve is closed

1.open or clean release valve.

Air motor won’t run or

runs erratically

1. Leak in air line.

2. Inadequate air pressure

3. Air piston is sticking

1. locate leak, tighten

connections, or replace hose.

2. Set air pressure to 85-120 psi.

3. Lube air motor by adding a

small amount of oil to jack’s air

inlet

5