Jackco Model 65500A User Manual

Page 4

• Store the jack in a well-protected area where it will not be exposed to corrosive

vapors, abrasive dust, or any other harmful elements.

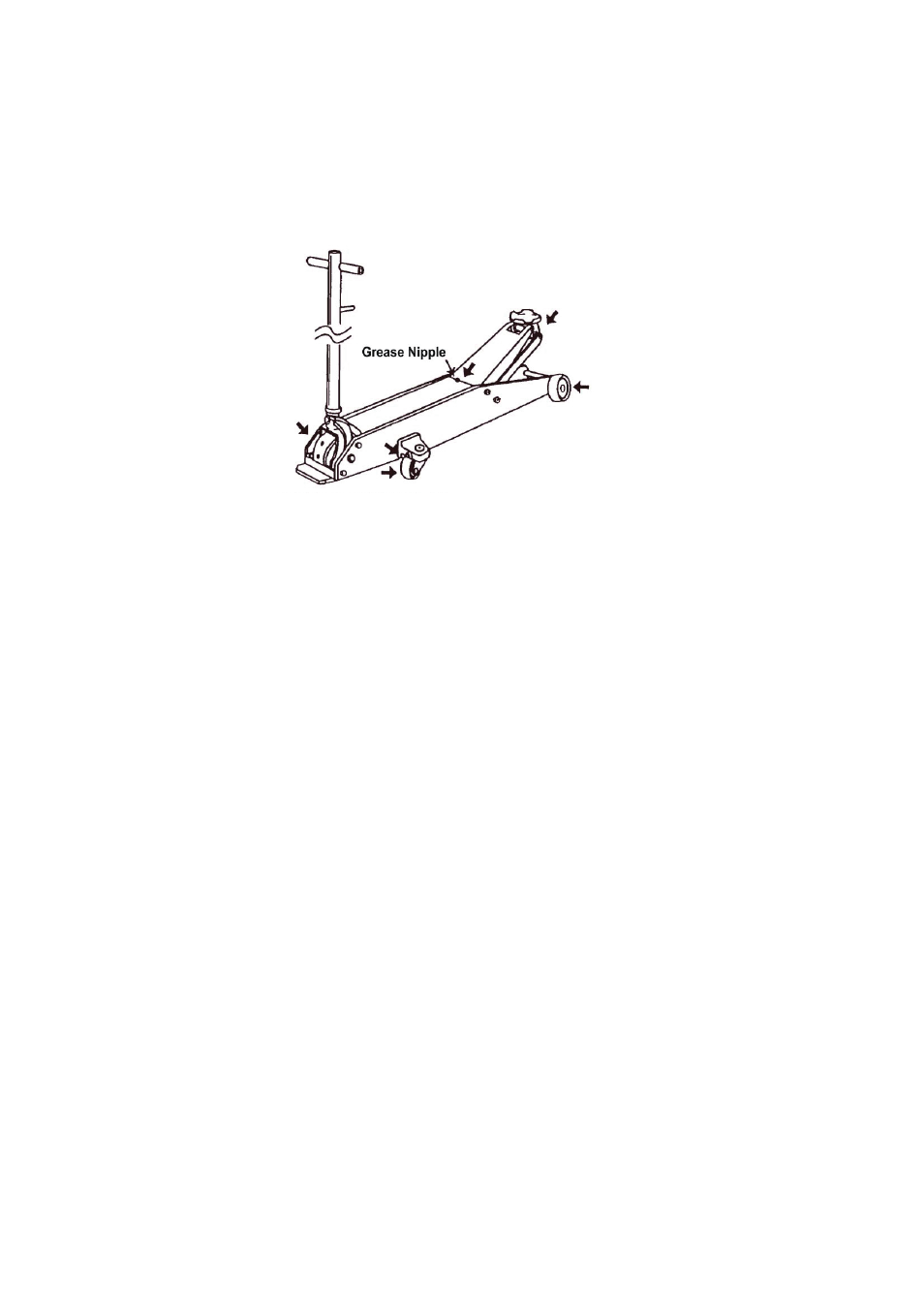

• Refer to the illustration, and regularly (at least once per month) lubricate the

moving parts shown.

• Add grease to upper arm grease nipple (shown) every three months.

• If necessary, add approved anti-wear hydraulic jack oil. Important: the use of

alcohol, hydraulic brake fluid, detergent motor oil, or transmission oil could

damage the seals and result in jack failure.

• Inspect the jack before each use. Take corrective action if any of the following

problems are found:

a. Cracked or damaged frame

b. excessive wear , bending, or other damage

c. Leaking hydraulic fluid

d. Scored, damaged piston rod

e. Malfunctioning swivel heads or

adjusting screws

f. Loose hardware

g. Modified or altered equipment

Preventive Maintenance

Important: Dirt is the greatest single cause of failure in hydraulic units. Keep the

service jack clean and well lubricated to prevent foreign matter from entering the

system. If the jack has been exposed to rain, snow, sand or grit, it must be cleaned

before it is used.

4