IDEC SG4 Type 4 Finger & Hand User Manual

Page 4

A Keep the receiver in a steady position and set the emitter until the yellow LED (

SYNC) is OFF.

This condition shows the effective alignment of the first beam (synchronisation beam).

B Rotate the emitter, pivoting on the lower optics axis, until the yellow LED (

LAST) is OFF.

NOTE: Ensure that the green LED (

NORMAL OP.) is steady ON.

C Delimit the area in which the green LED (

) is steady through some micro adjustments - for the first

and then for the second unit - so to have the maximum alignment (4) and then place both units in the

centre of this area.

D Fix the two units firmly using brackets.

Verify that the green LED (

) on the RX unit is ON and beams are not interrupted, then verify that

the red LED turns ON if even one single beam is interrupted SAFE(BREAK)

, condition where an

object has been detected).

This verification shall be made with the special cylindrical “Test Piece” having a size suitable to the

resolution of the device used (refer to paragraph 2.2.6 “Controls after first installation”).

E Switch OFF and ON the device in standard operating mode.

The alignment level is monitored also during device normal operation mode via display (see paragraph

7.2 on the manual inside of the attached CD-ROM).

Once the curtain has been aligned and correctly fastened, the display signal is useful both to check the

alignment and show a change in the environmental conditions (occurrence of dust, light disturbance and

so on) via signal level monitoring.

DIAGNOSTICS FUNCTION

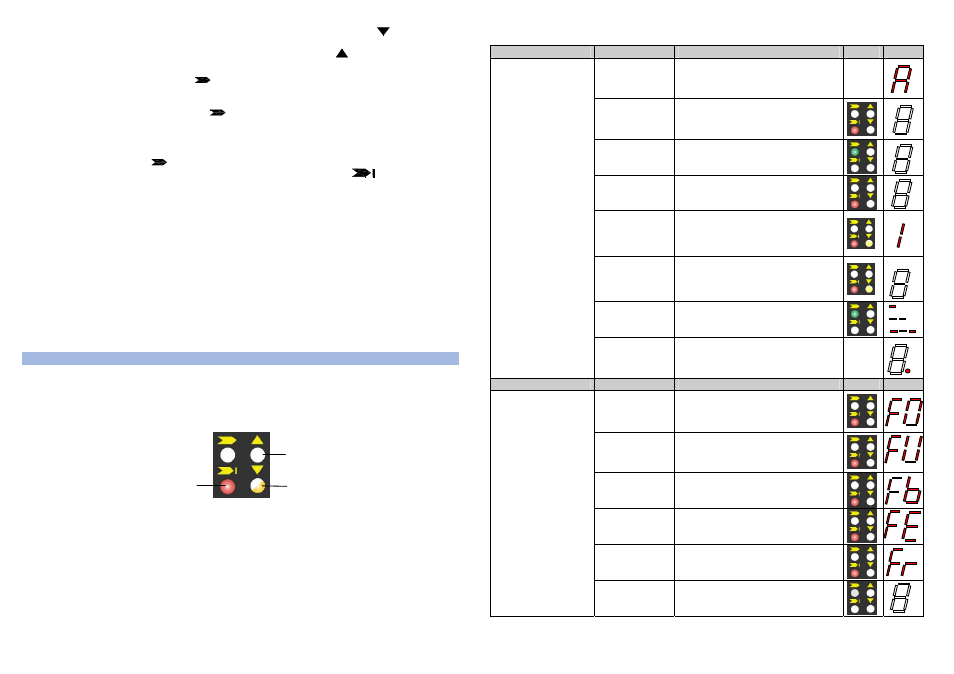

The operator can visualise the operating condition of the light curtains thanks to a one-digit display

positioned on both the RX and TX unit. SG4-B also has four LEDs on the RX unit and two LEDs on the TX

unit.

The figure below shows all signalling LEDs modes: OFF, ON and BLINKING.

4

The operator can evaluate the main causes of the system stopping or failure using the 7-segment display

and LEDs used to visualise the functions. For the receiver:

Function

Status

Meaning

LED

DIGIT

Alignment

See section 5

TEST

(red ON)

Light curtain being tested. OSSD status

shall be OFF

Emission

(OSSD ON)

(green ON)

Light curtain working in normal operating

conditions

Interruption

(OSSD OFF)

(red ON)

Light curtain working in safety block

conditions.

Interlock

Beams free

(red ON

yellow ON)

Light curtain in interlock, waiting for

restart. OSSD status must be OFF

Interlock

Beams interrupted

(red ON

yellow ON)

Light curtain in interlock. OSSD status

must be OFF

Signal level

Minimum (1 bar)

Medium (2

bar)

Maximum (3 bar)

Normal operation

EDM enabled

EDM function is selected

Function

Type

Check and repair

LED

DIGIT

OSSD error

(red ON)

Check OSSD connections. Make sure that

they are not in contact with one another or

with the supply cables, then Reset. If the

failure continues contact DATASENSOR

Internal error

(red ON)

Switch OFF and switch ON the power

supply circuit. If the failure continues

contact DATASENSOR

Optical error

(red ON)

Reset. If the failure continues contact

DATASENSOR

EDM error

(red ON)

Check EDM connections and lines. If the

failure continues contact DATASENSOR

Restart selection

error (red ON)

Check the man/auto restart connection. If

the failure continues contact

DATASENSOR

Error status

No power supply

(LEDs OFF)

Check connections and input voltage

value. If the failure continues contact

DATASENSOR

5

LED ON

LED OFF

LED BLINKING