Part 3, Heater piping, A. piping to the pool filter – HTP SSU-20PH User Manual

Page 5: B. piping to the boiler, Part 3 – heater piping

5

LP-21A Rev. 3.24.14

For winterizing, the pool heater must be completely drained and have one gallon of non-toxic, food-grade propylene

glycol, FDA rated as GRAS (Generally Recognized As Safe) pumped into the heat exchanger to prevent freezing.

Choose a location for the water heater as centralized to the piping and electrical system as possible. Carefully consider

how boiler and pool piping will be routed before choosing final pool heater location. Place the water heater so that the

drain, controls, and inlets/outlets are easily accessible for service.

This water heater must be installed vertical on a level surface.

Locate the water heater where any leakage from the related piping, tank, or connections will not result in damage to

surrounding areas or lower floors. HTP WILL NOT be held liable for leakage damages.

This water heater must not be located near flammable liquids such as gasoline, butane, liquefied propane, adhesives,

solvents, paint thinners, etc., as the controls of this water heater could ignite these vapors and cause an explosion,

resulting in property damage, severe personal injury, or death.

High heat sources (sources generating heat 100

o

F / 37

o

C or greater, such as stove pipes, space heaters, etc.) may

damage plastic components of the water heater as well as plastic vent pipe materials. Such damages ARE NOT covered

by warranty. It is recommended to keep a minimum clearance of 8” from high heat sources. Observe heat source

manufacturer instructions, as well as local, state, provincial, and national codes, laws, regulations and ordinances when

installing this water heater and related components near high heat sources.

PART 3 – HEATER PIPING

It is mandatory that all plumbing be done in accordance with federal, local, and state plumbing codes and practices.

Failure to properly install the water heater WILL VOID the warranty. It is also necessary to use both thread tape and pipe

dope on all mechanical plumbing connections.

A. PIPING TO THE POOL FILTER

The pool water side piping (pool in and pool out, see Figure 2

) is recommended to be 1 ½” PVC. A bypass will be

necessary between the inlet and outlet of the pool heater (see Figure 2). The bypass will allow the boiler to keep up with

the pool heater. If the bypass is not installed, the boiler may not be able to provide adequate temperature.

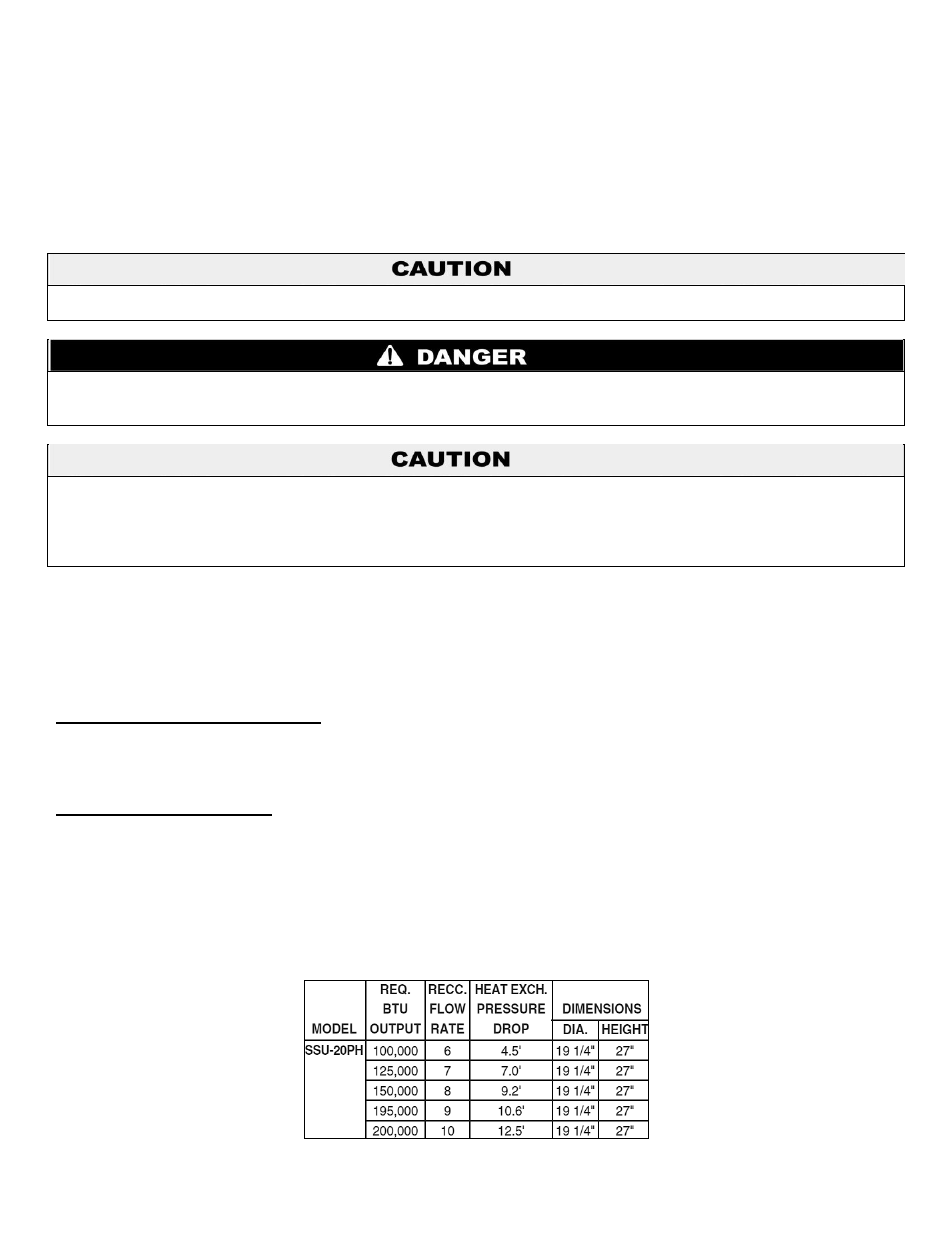

B. PIPING TO THE BOILER

Piping between the boiler and pool heater should be 1 ¼” copper. It is very important to properly size the boiler circulator

to match total system flow rates, pressure drop (feet of head), and boiler output (see Table 1). For example, if the boiler is

100,000 BTU/H, the system requires a 6 GPM flow rate through the heat exchanger. If the boiler is 125,000 BTU/H, the

system requires a 7 GPM flow rate through the heat exchanger.

To achieve proper flow rates, calculate friction loss for the length of piping, plus the number of fittings, elbows, tees, pool

heat exchanger, etc. Pool heat exchanger friction loss is 4.5’ at 6 GPM, 7’ at 7 GPM, and 9.2’ at 8 GPM. The minimum

boiler temperature must be maintained at 160

o

F or higher. Low boiler temperature will dramatically reduce the life of the

boiler.

Table 1

– Pressure Drop through the Heat Exchanger