J. boiler tank control, K. circulator sizing, L. boiler back-up heat exchanger (sb models only) – HTP SSC-119SE User Manual

Page 24

24

LP-200 REV. 3.25.14

I. BOILER BACK-UP HEAT EXCHANGER

CONNECTION (SB MODELS ONLY)

The boiler heat exchanger connections are located in the

front of the solar water heater. Use a 1” minimum pipe

size when connecting zone valves or circulators.

The inlet of the circulator must be connected to the hot

outlet side of the boiler. Be sure the direction of the arrow

on the circulator is facing toward the flow direction from

the boiler to the boiler inlet of the water heater. On the

water heater, the boiler return must be connected to the

return side of the boiler. The return from the heating loop

should have a flow check or swing check valve installed

before the return pipe from the boiler heat exchanger.

J. BOILER TANK CONTROL

Insert the boiler tank control into the control well provided

in the front of the water heater. Wire the boiler tank

control to the boiler control or relay center. Additional

equipment may be needed in order to wire the control to

the existing system. Controls also have the ability to

monitor and display solar collector temperature and upper

and lower tank temperature. See Figure 9 for installation

detail.

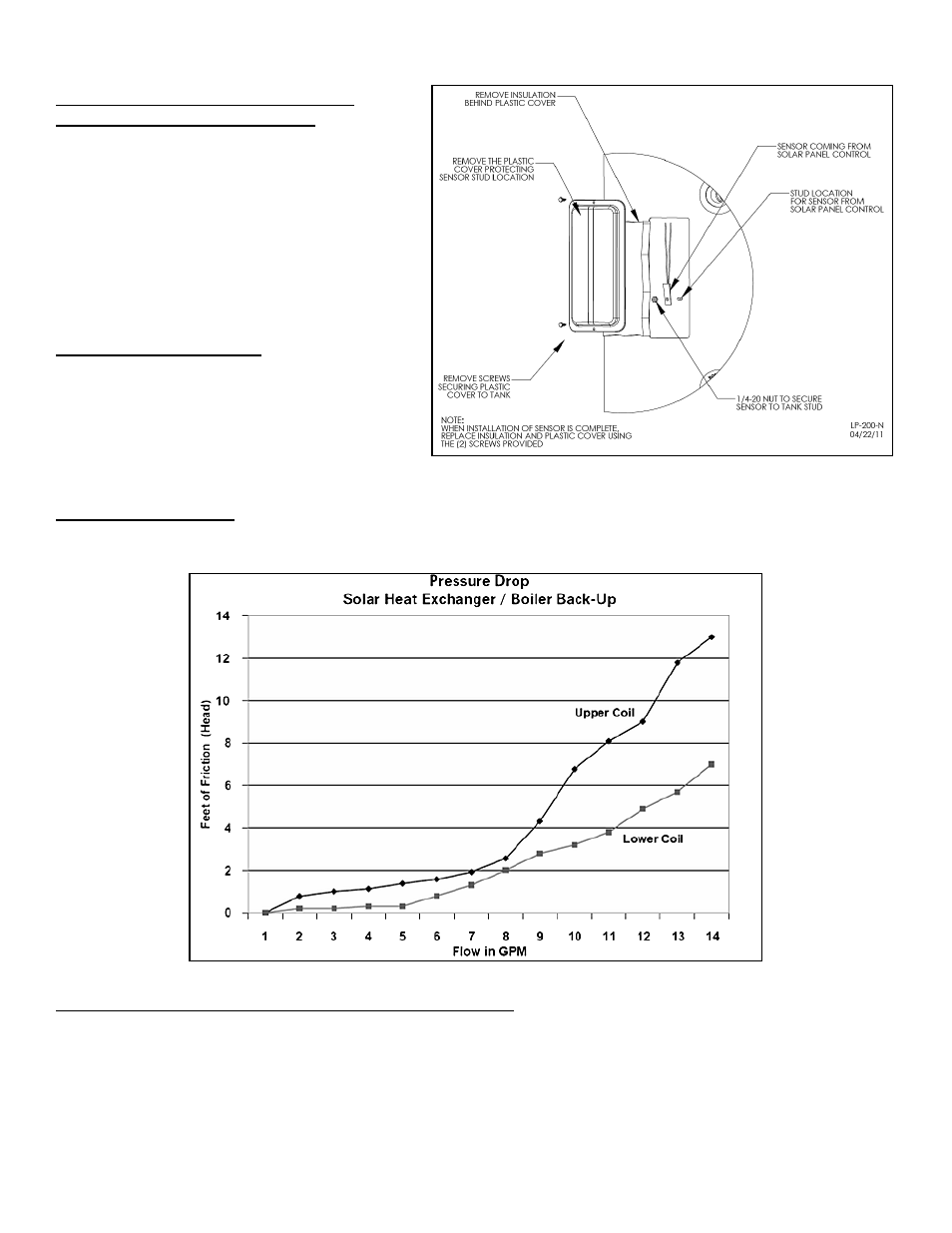

K. CIRCULATOR SIZING

The circulator pump must be sized for the related piping and pressure drop of the heat exchanger, and for situations specific to your

solar system. The following graph represents the pressure drop of the solar heat exchanger. Consult the solar panel manufacturer for

flow requirements to assist in pump selection.

Figure 10

– Pressure Drop through the Solar Water Heater Heat Exchanger

L. BOILER BACK-UP HEAT EXCHANGER (SB MODELS ONLY)

To assure the correct flow through the boiler back-up heat exchanger, refer to Figure 10 to correctly size the circulator to the boiler or

auxiliary heat exchanger. HTP recommends a flow rate of 1 gpm for every 10,000 BTU based on a 20

o

F temperature difference

between the supply and return of the heat exchanger.

Example: Boiler is 100,000 BTU / 10,000 BTU = 10 gpm flow rate. The heat exchanger at 10 gpm will require a circulator that will

operate at 8 feet of friction.

Figure 9

– Sensor Installation Detail