Harrington Hoists and Cranes SH Hoist User Manual

Page 8

8

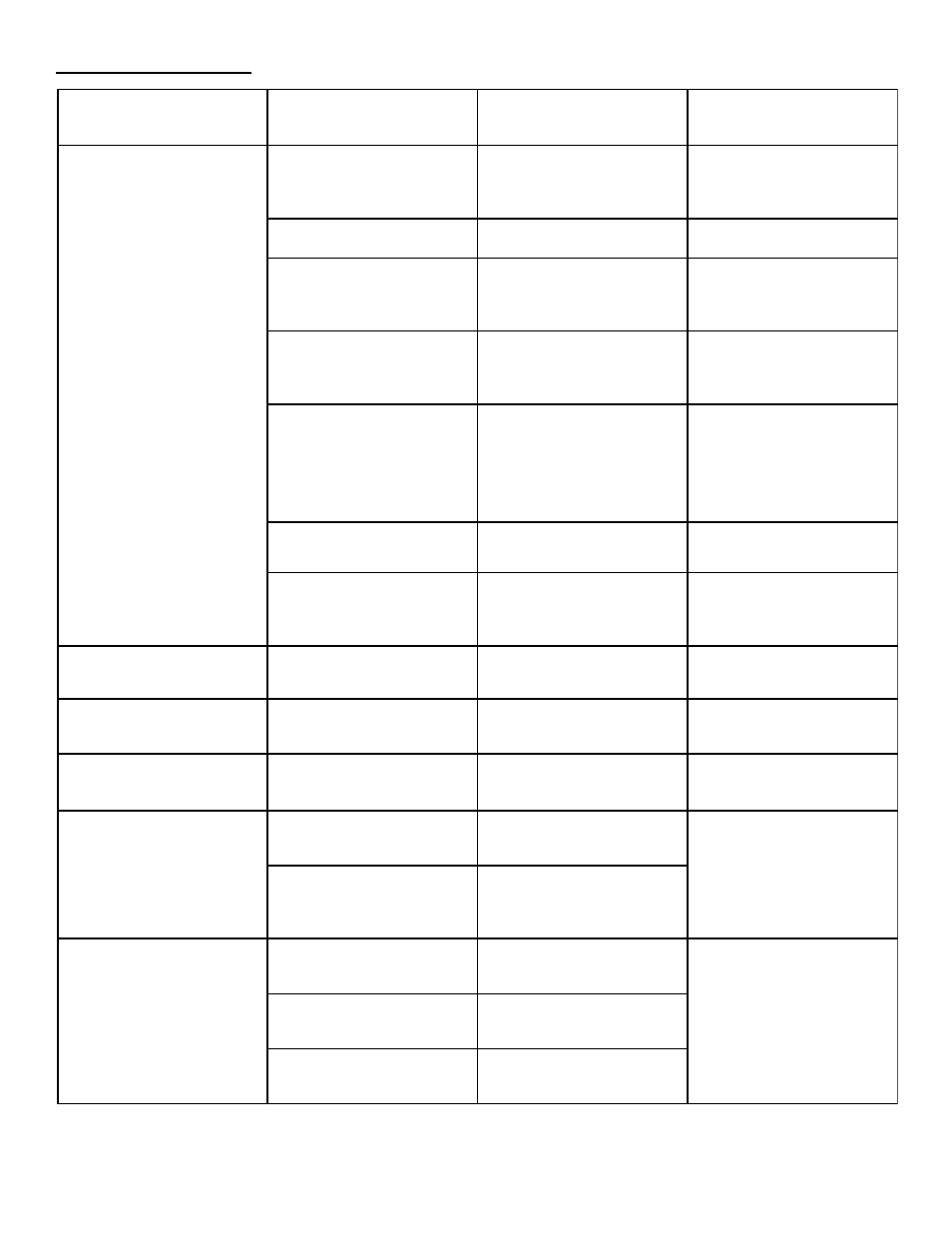

TROUBLE SHOOTING

Trouble

Cause

Remedy

Remarks

Will not move.

Will not lift.

Broken fuse

Replace fuse of same

rating

Do not use copper wire

as substitute. Do not

use fuse of larger rating.

Broken limit switch

Replace limit switch

Broken condensor

Replace with new ones. Replacement should be

made as one complete

set (1 pair).

Voltage drop

Check the voltage with

a voltohm meter and

check wiring.

Interrupt the operation.

Discontinuity in power

supply cable

Discontinuity in push

button control cord

Check discontinuity in

the cable where cable is

subject to frequent

bending, and repair

cable and cord.

The motor turns

immediately but does

not rotate.

Overload

Check the weight of the

load.

Slipping due to poor

friction clutch

performance

Replace with factory

adjusted friction clutch.

Brake slips

Worn brake shoe

Replace brake shoe if

necessary.

Clicking sound is heard Worn load chain

Rusted load chain

Replace load chain if

necessary.

Trolley will not stop

Angulation of beam

Oil-stained beam

Correct the angulation

Remove oil, clean

Electrical leak

Poor grounding work

Provide correct

grounding

Leak at places other

than the electric chain

hoist may sometimes be

responsible.

Foreign matters or

moisture depositing on

electrical parts

Remove foreign matter

from or dry the electrical

parts.

Oil leak

Oil plug missing

Install the regular oil

plug.

If oil leak occurs at

places other than oil

plug, disassemble and

check thoroughly for the

cause and repair.

Loose oil plug

Tighten the plug.

Oil plug packing missing Use new packing.