Lubrication – Grove Gear Helical-Inline Cast Iron (R Series) User Manual

Page 4

Phone: (262) 878-1221

Fax: (262) 878-1968

4

Lubrication

Lubrication

All standard reducers ordered from the factory are

filled with lubricant to the correct level for the mounting

position specified to operate within a 30° to125° F

ambient temperature range. Quad reduction units have

separate oil sumps and must be filled/checked

independently. Prior to startup, verify that the oil is at the

level shown on the drawings on pages 6 and 7. If the

ambient temperature will be outside the range for the

lubricant installed at the factory, drain and refill the

reducer with the proper viscosity lubricant prior to use.

If the mounting position is changed, the oil

quantity must be adjusted to obtain the proper oil level

per these Lubrication Instructions. Mounting position must

be one shown on pages 6 and 7. Consult the factory if you

are not certain of the correct oil level or quantity. Consult

the factory for mounting positions not shown.

In the Food and Drug Industry (including

animal food), consult the lubrication supplier for

recommendation of lubricants which are acceptable to the

Food and Drug Administration and/or other authoritative

bodies having jurisdiction. Factory supplied oil is not

suitable for these applications or this industry.

Do not mix different oils in the reducer. Oil

should be compatible with Nitrile seal material.

Use of an oil with an EP additive on units

with backstops may prevent proper operation of the

backstop. Injury to personnel, damage to the reducer or

other equipment may result.

Change Intervals: After the first 500 hours or one month

in service, whichever comes first, drain the oil from the

reducer. Flush and refill with new oil. TorqueLine units

utilize extreme pressure lubricants which protect the

teeth in the event of the oil thinning out due to local

temperature rise, or high pressure due to accidental

overloads. These oils are liable to form sludge after

continuous service. The oil should be changed after every

1500 hours of operation, or more often as conditions may

dictate. The grades of oil shown below are for normal

conditions of duty and ambient temperature. High

ambient temperatures cause the oil to thin out and

reduce its protective qualities. In such cases it will be

necessary to utilize heavier grades than shown. Conversely,

low temperatures will necessitate a thinner grade,

otherwise trouble may be experienced with burning out of

motors at starting. In this connection, the pour point of the

oil must be less than the lowest ambient temperature to

be encountered.

The precision-made gears and bearings in Grove Gear

Speed Reducers require high-grade lubricants of the

proper viscosity to maintain trouble-free performance. For

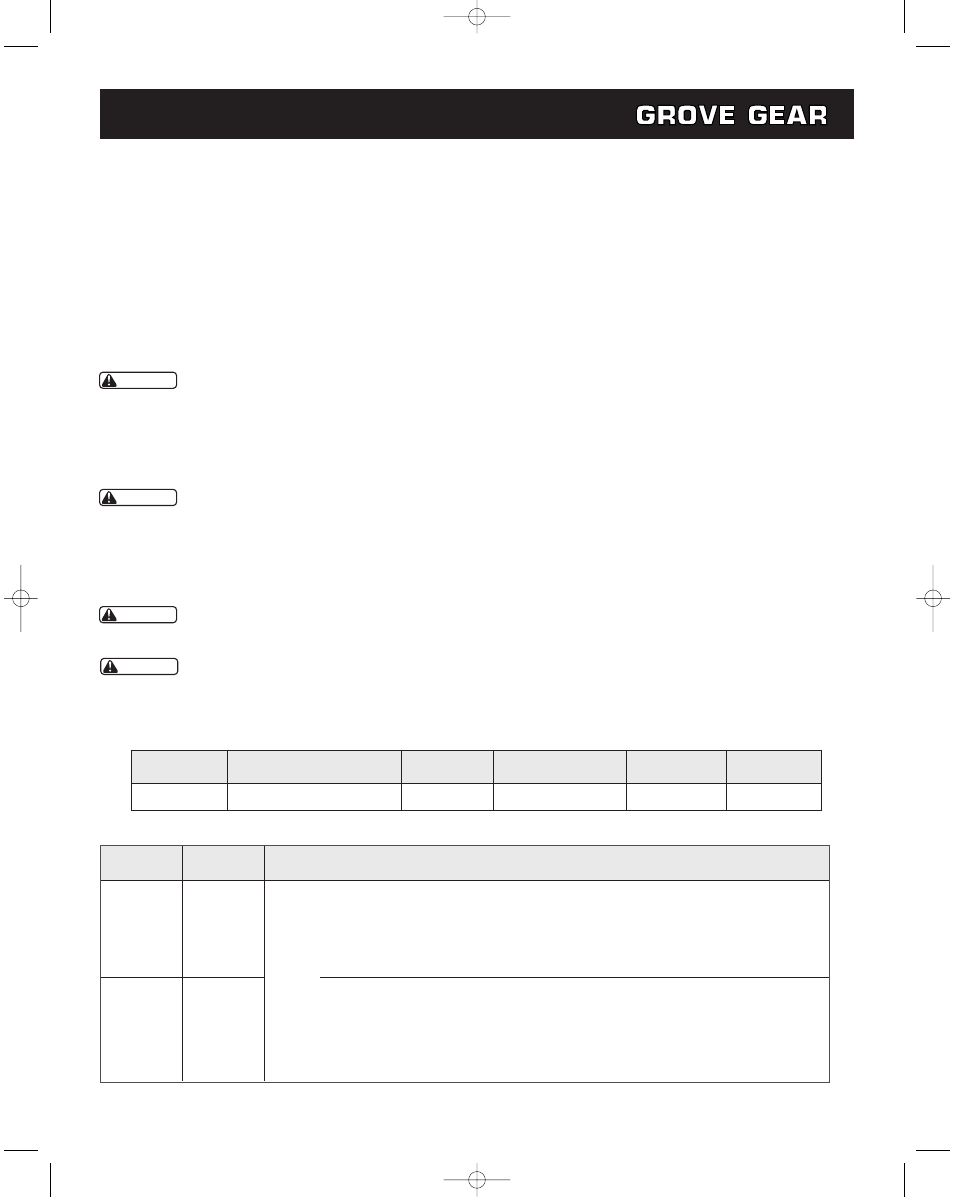

best results, use lubricants on the following chart for

TorqueLine gear reducers for ambient temperatures of 30°

to 125° F.

CAUTION

CAUTION

CAUTION

Mobil

Chevron

Texaco

Citgo Petroleum

Shell Group

Castrol

Corporation

Corporation

Inc.

Corporation

of Companies

Limited

Mobilgear 630

Gear Compound EP ISO220

Meropa 220

EP Compound 220

Omala 220

Alpha SP220

WARNING

P

e

rmanentl

y

Grease Lubed

Approximate Oil Capacities Double Reduction (Pints)

Model

Mounting

UNIT SIZE

Type

Position

7172

8272

8372

8472

8572

8672

8772

8872

8972

81072

C-Frame

B3 & B5 Floor

1.0

1.0

1.6

1.6

3.3

4.3

6.8

16.9

22.5

or

B8 Ceiling

1.8

1.8

3.0

3.0

5.2

7.4

11.4

20.1

28.4

Gearmotor

B6 & B7 Wall

1.5

1.5

2.3

2.3

4.2

6.1

10.1

19.6

25.5

Style

V5 & V1

Vertical

1.4

1.4

2.5

2.5

4.0

5.5

10.0

13.6

19.4

Shaft

B3, B5 Floor

1.0

1.0

1.6

1.6

3.3

4.3

6.8

16.9

22.5

Input

B8 Ceiling

2.2

2.2

3.1

3.1

5.4

7.8

13.2

23.3

33.3

Style

B6 & B7 Wall

1.6

1.6

2.4

2.4

4.2

6.1

11.0

21.6

30.0

V5 & V1

1.4

1.4

2.5

2.5

4.0

5.5

10.0

13.6

19.4

Vertical

Helical InlineDrs,7-07 8/2/07 11:50 AM Page 4