Shaft connections, Instruction manual – Grove Gear Helical-Inline Aluminum (P Series) User Manual

Page 5

Shaft Connections

provide suitable guards in accordance with OSHA standards.

Input and output shaft extension diameter tolerance is +0.000”; -0.001” for shafts up to 1.375” diameter. The fitted component must be machined to ensure

proper fit .

DO NOT drive coupling hub, pinion, sprocket or pulley on the shaft. An endwise blow on the shaft may damage gears and bearings. Coupling hubs,

pinions, sprockets or pulleys must be pushed onto the shaft using a screw jack device fitted into the threaded hole provided in the end of the shaft, see

Table 3 below.

Output Shaft

Input Shaft

Drive Size

Tap Size

Depth

Tap Size

Depth

717

1/4-20

.62

1/4-20

.62

727

5/16-18

.75

1/4-20

.62

747

5/16-18

.75

5/16-18

.75

757

5/16-18

.75

5/16-18

.75

Table 3 - Shaft End threaded Holes - Inches

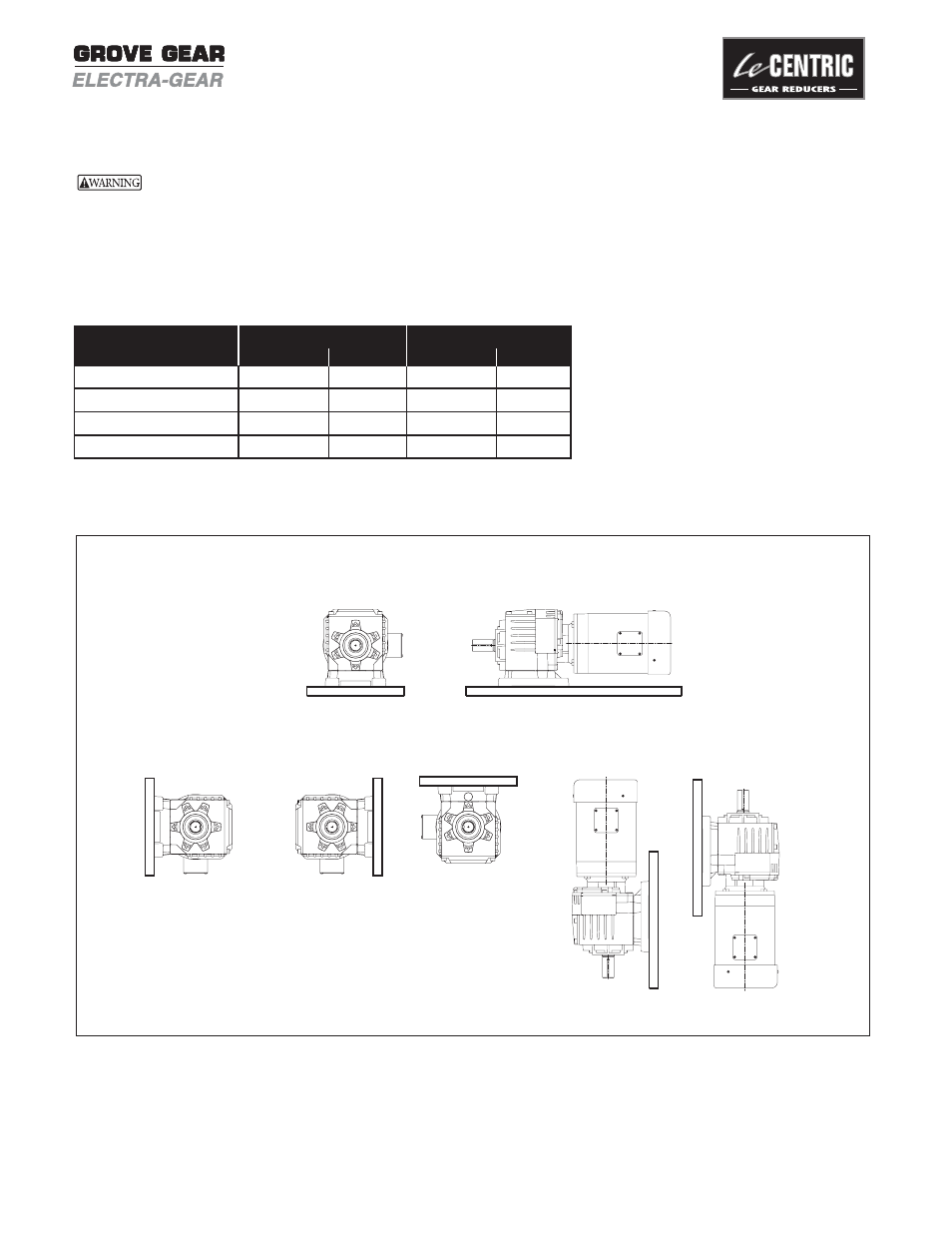

H7

H6

H3 (Standard Position)

V6*

V5

H8

Standard mounting position is H3. All reducers will be filled to this level, unless otherwise specified.

**Not Recommended

Figure 1 - Reducer Mounting Positions

INSTRUCTION MANUAL

™