Operating manual – Robinair 15120A_15121A User Manual

Page 4

Operating Manual

3

15121A Wiring Instructions

The CoolTech vacuum pump features dual

voltage ranges. Before operating the pump,

read and follow these rewiring instructions (if

necessary) to be certain your pump is wired for

the appropriate voltage.

CAUTION: To prevent personal injury,

unplug the unit before beginning service

work. Incorrect use or connections can

cause electrical shock. Only qualified

personnel should perform service work.

The CoolTech vacuum pump is factory wired for

a high voltage of 220 volts. To wire the switch

for a low voltage range of 110 volts to 127 volts,

follow these steps:

1. Disconnect unit from the AC power source.

2. Loosen the screws on the plate at the rear

of the motor, and carefully move the plate

aside to clear the opening.

3. Disconnect the leads, and reconnect for low

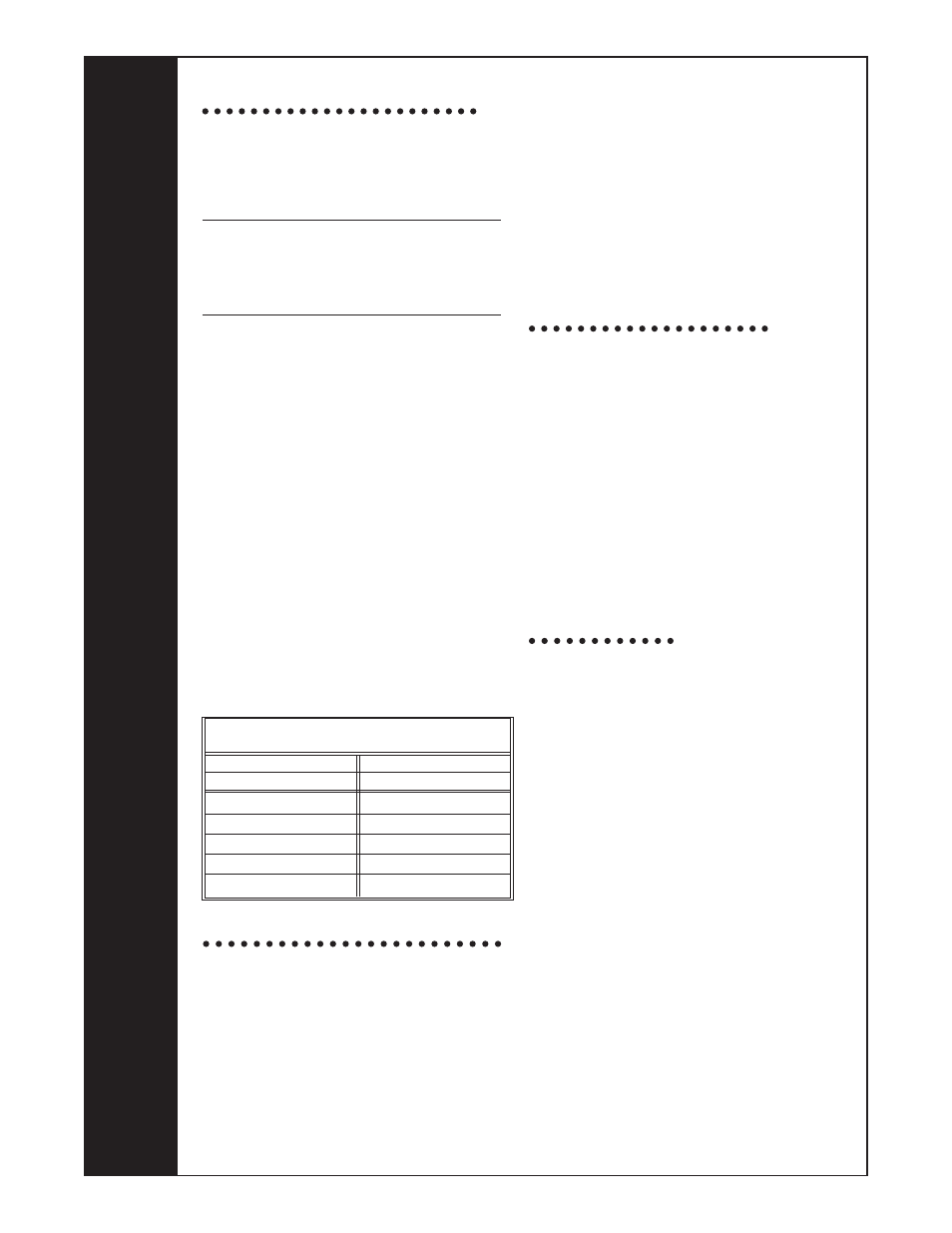

voltage according to the following chart.

(High voltage connections are also shown,

in case you want to rewire at some time.)

4. Verify all connections are secure, and there

are no short circuits. Verify the grounding

connector is correctly connected.

5. Reinstall the plate on the rear of motor with

the screws that were loosened in Step 2.

6. Use a continuity tester to check for short

circuits before reconnecting the unit to the

AC power source.

To use the gas ballast feature

Moisture from the A/C-R system, carried into the

pump as a vapor, tends to condense into a liquid

and combine with the vacuum pump oil. When

moisture contaminates pump oil, it reduces the

pump’s ability to reach its ultimate deep vacuum.

The gas ballast valve purges a small amount

of atmospheric air through the exhaust

chamber. This extra volume of air mixes with

the vapor from the refrigerant system to prevent

condensation and to help exhaust moisture in

the form of vapor from the pump.

To use the gas ballast, start the pump and open

the gas ballast valve. The valve is located beside

the handle, opposite the inlet fitting. When the

system has reached approximately 1000–3000

microns, close the gas ballast valve to allow the

pump to pull down to its ultimate vacuum level.

The gas ballast valve may be opened or closed

at any time during pump operation. It is fully open

at two turns counterclockwise. Note: Robinair

recommends the use of a thermistor vacuum

gauge to most accurately measure vacuum levels.

To shut down the pump

To help prolong pump life and promote easy

starting, follow these procedures for shutdown:

1. Close the manifold valve between the pump

and the system.

2. Turn the Iso-Valve to the CLOSED position.

3. Remove the hose from the pump inlet.

4. Turn the pump power switch to OFF, then

OPEN the Iso-Valve for a few seconds to

relieve any vacuum inside the pump.

5. Cap the inlet port to prevent any contamination

or loose particles from entering the port.

To maintain your high

vacuum pump

For maximum performance, Robinair recommends

changing vacuum pump oil after each use.

Vacuum pump oil

The condition and type of oil used in any high

vacuum pump are extremely important in

determining the ultimate attainable vacuum. Robinair

recommends the use of our Premium High Vacuum

Pump Oil. This oil has been specifically blended

to maintain maximum viscosity at normal running

temperatures and to improve cold weather starts.

Robinair Premium High Vacuum Pump Oil is

available in convenient pint, quart, or gallon

containers. Order by part number:

13201 — Pint (shipped 12 pints per case)

13203 — Quart (shipped 12 quarts per case)

13204 — Gallon (shipped 4 gallons per case)

Oil change procedure

1. Run the pump until warm.

2. Remove the OIL DRAIN cap. Drain

contaminated oil into a suitable container and

dispose according to local regulations.

Oil can be forced from the pump by opening

the inlet and partially blocking the exhaust

with a cloth while the pump is running. Do not

operate the pump for more than 20 seconds

using this method.

EMERSON MOTOR

ELECTRICAL CONNECTION TABLE

115V

220V

WIRE

TERMINAL No.

WHITE

4

BLACK

2

RED

5

BROWN

3

LINE

1 & 4

WIRE

TERMINAL No.

WHITE

3

BLACK

3

RED

5

BROWN

6

LINE

1 & 4