Troubleshooting guide – Ransburg RCS-100FP Fluid Pump Kit 70945 User Manual

Page 17

LN-9227-00

13

13

13

13

13

Fluid Pump Motor Speed Control Station - Maintenance

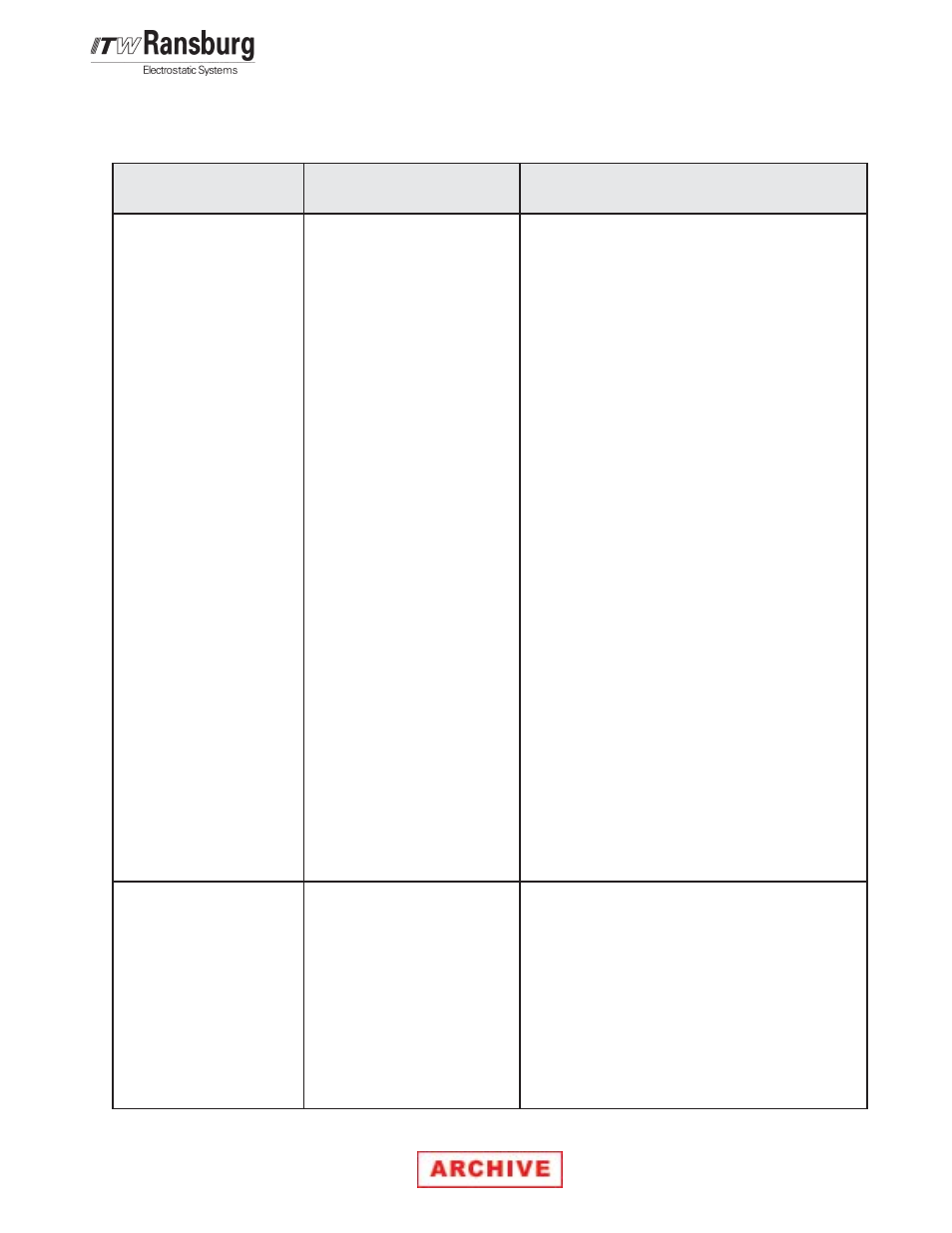

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Figure 5: Troubleshooting Guide

Figure 5: Troubleshooting Guide

Figure 5: Troubleshooting Guide

Figure 5: Troubleshooting Guide

Figure 5: Troubleshooting Guide

General Problem

General Problem

General Problem

General Problem

General Problem

Cause

Cause

Cause

Cause

Cause

Solution

Solution

Solution

Solution

Solution

Motor Will Not Start

Controller Line Fuse

Blows When AC Line

Power is Applied to the

Controller

1. AC line open

2. Operator controls inop-

erative or connected

incorrectly

3. Relay 1RE bad

4. Line voltage selection

jumper J1 in wrong po-

sition

5. Controller not enabled

6. Controller not adjusted

correctly

7. Open shunt field wind-

ing or wiring to the mo-

tor shunt field, causing

loss of torque

8. Motor failure

9. Control board failure

1. Wiring faulty or incor-

rect

2. Circuit, component, or

wiring grounded

3. Motor shunt field

shorted or grounded

4. Control board failure

1. - Be sure rated AC line voltage is ap-

plied to controller.

- Measure for 115 VAC between TB1-

L2 and 1RE-8.

2. Hold HV control ON, measure HV inter-

lock input voltage.

115 VAC - TB3-1 to TB3-3 -or-

24 VAC - TB3-2 to TB3-3 -or-

24 VDC - TB3-2 to TB3-3

3. Be sure HV control ON signal is present

(above). Measure for 115 VAC between

TB1-L1 and TB1-L2. If not, replace 1RE.

4. Be sure J1 is in the 115 VAC position.

5. Be sure that TB2-8 is jumpered to TB2-9.

6. Turn the ACCEL and CUR LMT potenti-

ometers fully clockwise (100%).

7. Check the motor shunt field and associ-

ated circuitry for a loose or broken wire.

8. Repair or replace motor.

9. Repair or replace the controller.

1. Check all external wiring terminating in

the controller.

2. Remove ground fault.

3. Repair or replace motor.

4. Repair or replace controller.