Ransburg Serial Digital Module 76911 User Manual

Page 7

LN-9257-07.1

4

Serial Digital Module - Safety

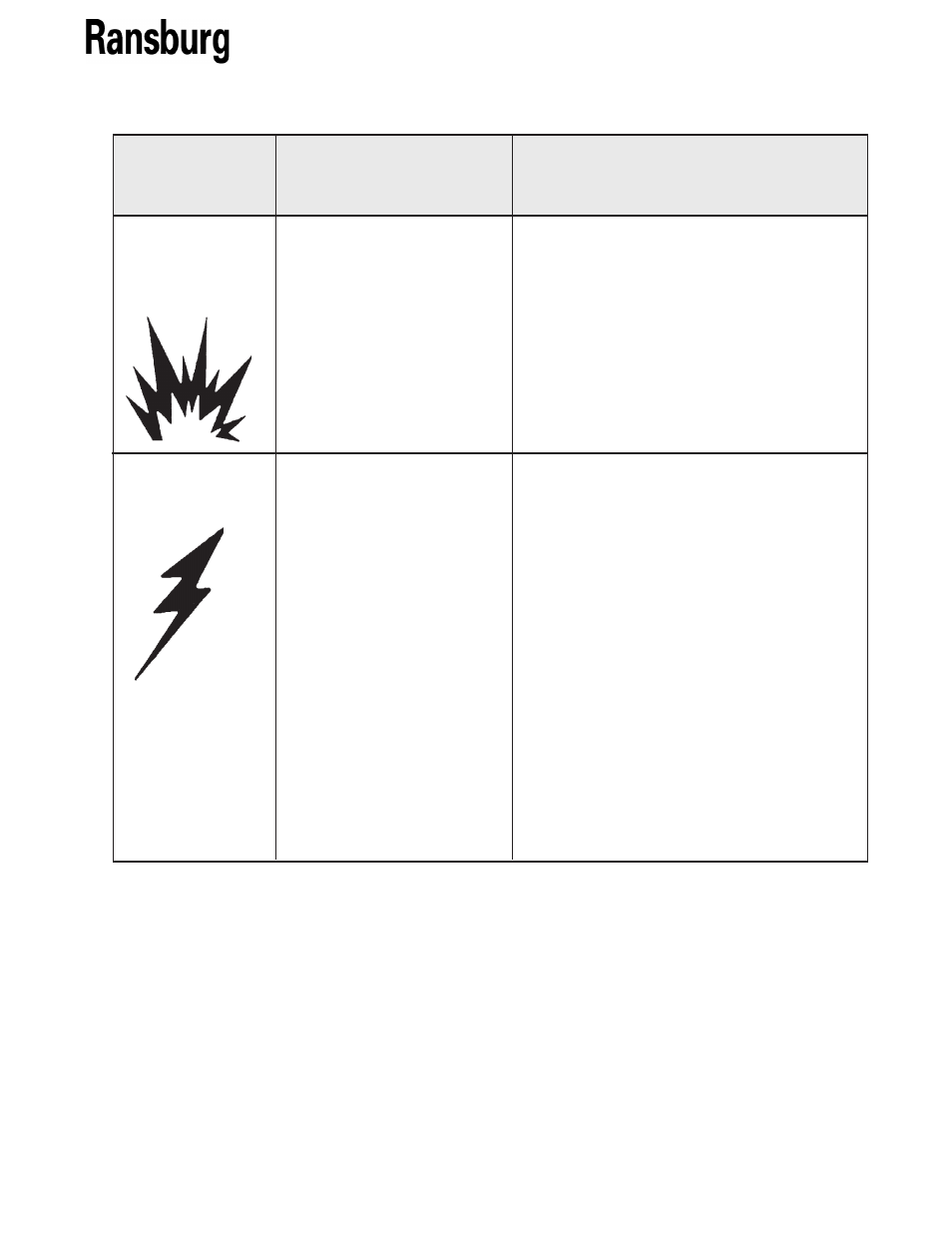

AREA

Tells where hazards

may occur.

HAZARD

Tells what the hazard is.

SAFEGUARDS

Tells how to avoid the hazard.

Spray Area /

High Voltage Equip-

ment

This is a high voltage device that

can produce electrical arcs ca-

pable of igniting coating materials.

Parts being sprayed must be supported on convey-

ors or hangers and be grounded. The resistance

between the part and ground must not exceed 1

megohm. (Reference NFPA-33.)

A safe distance must be maintained between the

parts being coated and the atomizer bell. A distance

of at least 1 inch for each 10 KV of power supply

output voltage is required at all times.

Parts must be supported so that they will not swing

and reduce the clearance specified above.

All electrically conductive objects in the spray area,

with the exception of those objects required by the

process to be at high voltage, must be grounded.

Unless specifically approved for use in hazardous

locations, the power supply and other electrical

equipment must not be used in Class I, Division 1

or 2 locations.

Explosion Hazard/

Incompatible Materi-

als

Halogenated hydrocarbon sol-

vents for example: methylene

chloride and 1,1,1,-Trichloroeth-

ane are not chemically compatible

with the aluminum that might be

used in many system compo-

nents. The chemical reaction

caused by these solvents react-

ing with aluminum can become

violent and lead to an equipment

Aluminum is widely used in other spray application

equipment - such as material pumps, regulators,

triggering valves, etc. Halogenated hydrocarbon

solvents must never be used with aluminum equip-

ment during spraying, flushing, or cleaning. Read

the label or data sheet for the material you intend

to spray. If in doubt as to whether or not a coating

or cleaning material is compatible, contact your

material supplier. Any other type of solvent may

be used with aluminum equipment.